- | - | |

Model 5040 | Form # Z397 | |

Date | ||

@Câ@ | ||

318'' Sq. Drive Butterfly | ||

Lever ImpactWrench | ||

IMPORTANT |

|

Read these instructions carefully before installing,operating,servicing or repairingthis tool. Keep these instructions in a safe accessible place.

2

SAFETY MESSAGES | 1 | A WARNING |

| 1 | Operator Instructions |

| |||||

Use |

|

|

| @ AlwaysWear Safety Goggles | ~ o r e & e nUse |

|

| ||||

Use - Safety Boots |

|

|

| @ ~arliearingProtection | Work Stations |

|

| ||||

Use |

| Putting Into Service |

| ||||||||

|

| Avoid Pmhged Exposure | Operating |

|

| ||||||

Use | YES |

|

|

|

| ||||||

| ,&I | ToVibration |

|

| Dismantling and Assembly. | ||||||

|

| Safety rules when using a 5040 ImpactWrench |

|

| |||||||

- Useoniy impactsocketsandextensions, universaljoints, |

| requirementswheninstalling, usingor maintainingthetool. | |||||||||

etc., ratedasbaingsuitablefor usewith impactwrenches. | - Take carethat the exhaustair doesnotpointtowards any | ||||||||||

- | to vibrationmay cause injury. |

|

| other person or material or substance that could be | |||||||

- R d A i m b a b W W W - N m m d |

| contaminatedby oil droplets.When first lubricatinga tool | |||||||||

b * M h b m d 6 d m * * |

|

|

| or if the tool exhaust has a high oil content, do not allow | |||||||

- Do not exceedthe maximumworking air pressure. |

| - | the exhaust air to come nearvery hotsurfaces or flames. | ||||||||

- Use personalprotectionequipment& r&mended. |

| Never lay the tool down untilthe working attachmenthas | |||||||||

- U s e - d r m & W w m |

|

|

|

| stoppedmoving. |

|

|

| |||

- If the tool appears to malfunction, remove from use | - When thet d is not in use,shut off the air supply and | ||||||||||

immediatelyandarrangefor s e w atxi repair. If it isnot |

| press throttle triggerhever to drain the supply line. If the | |||||||||

practicalto removet |

| d from service, thenshutoffthe air |

| t d is not to be used for a periodof time, first lubricate, | |||||||

supply to the t d and write or have written a warning |

| disconnectfrom airsupplyandstoreinadryaverageroom | |||||||||

note and attach it to the tool. |

|

|

|

| - | temperatureenvirmnt . |

|

| |||

- If tool is to be used with a balancer or other suspension | If the t d is passed from one user to a new or inexperi- | ||||||||||

device, ensure that the tool is firmly attached to the |

| enceduser, makesure these instructionsare availableto | |||||||||

suspension/supportdevice. |

|

|

|

| - | be passedwith the t d . |

|

| |||

- When operating the tool, always keep the body and | Do not remove any manufacturer fitted safety devices | ||||||||||

particularlythe handsawayfrom the workingattachment |

| where fitted, i.e., | wheel guards, safety trigger, speed | ||||||||

fixed to the t d . |

|

|

|

|

|

| - | governors, etc. |

|

|

|

- The tool is not electricallyinsulated. Never use the tool if | Whereverpossible,secure workpiece withdamps, a vise, | ||||||||||

there is any chance of coming into contact with live |

| etc. to make it rigid.so it does not move during the work | |||||||||

electricity. |

|

|

|

|

|

|

| operation. Keepgood balanceat all times. Do notstretch | |||

- Always when usingthe t d , adopt a firm footing and/or |

| or overreach. |

|

|

| ||||||

position and grip the tool sufficiently | only to overcome | - Try to match the t | d to the work operation. Do not use a | ||||||||

any reaction forces that may result from the t | d doing |

| tool !hat is too light or heavy for the work operation. If in | ||||||||

work. Do not overgrb. |

|

|

|

|

| doubt, seekadvice. |

|

| |||

- Use only correct $are | partsfor maintenanceand rew'r. | - In general terms, this tool is not suitable for underwater | |||||||||

Do not improvise or make temporary repairs. Maior |

| useor | |||||||||

servicing and repairs should only be cahed out |

| manufacturer. |

|

|

| ||||||

wrsons trained to do so- |

|

|

|

| - Try to makesure that the work area is dear to enablethe | ||||||

- Do not lock, tape, wire, etc. the 'On/0ff'valve in 'On' |

| work task to be performed safely, If practical and | |||||||||

position.The throttletriggerhever,etc. must alwaysbefree |

| possible, try to dear unnecessary obstructions before | |||||||||

to returnto the 'Off'positionwhen released. |

|

|

| starting work. |

|

|

| ||||

- Awa shut off the air supply to the tool and press the | - h a y s use air hose and couplings with minimum work- | ||||||||||

'0n/&'valve to exhaust the air from the feed hose |

| ing pressure ratings at least 1 1/2 times the maximum | |||||||||

before fitting, removing or adjusting the woking attach- |

| working pressure ratingof the tool. |

|

| |||||||

ment fitted to the t d . |

|

|

|

|

|

|

|

|

| ||

- Eeforeusingthe tool,makesurethat a | 1 |

|

|

|

|

| - |

| |||

shut off device has been fitted to the- |

|

|

|

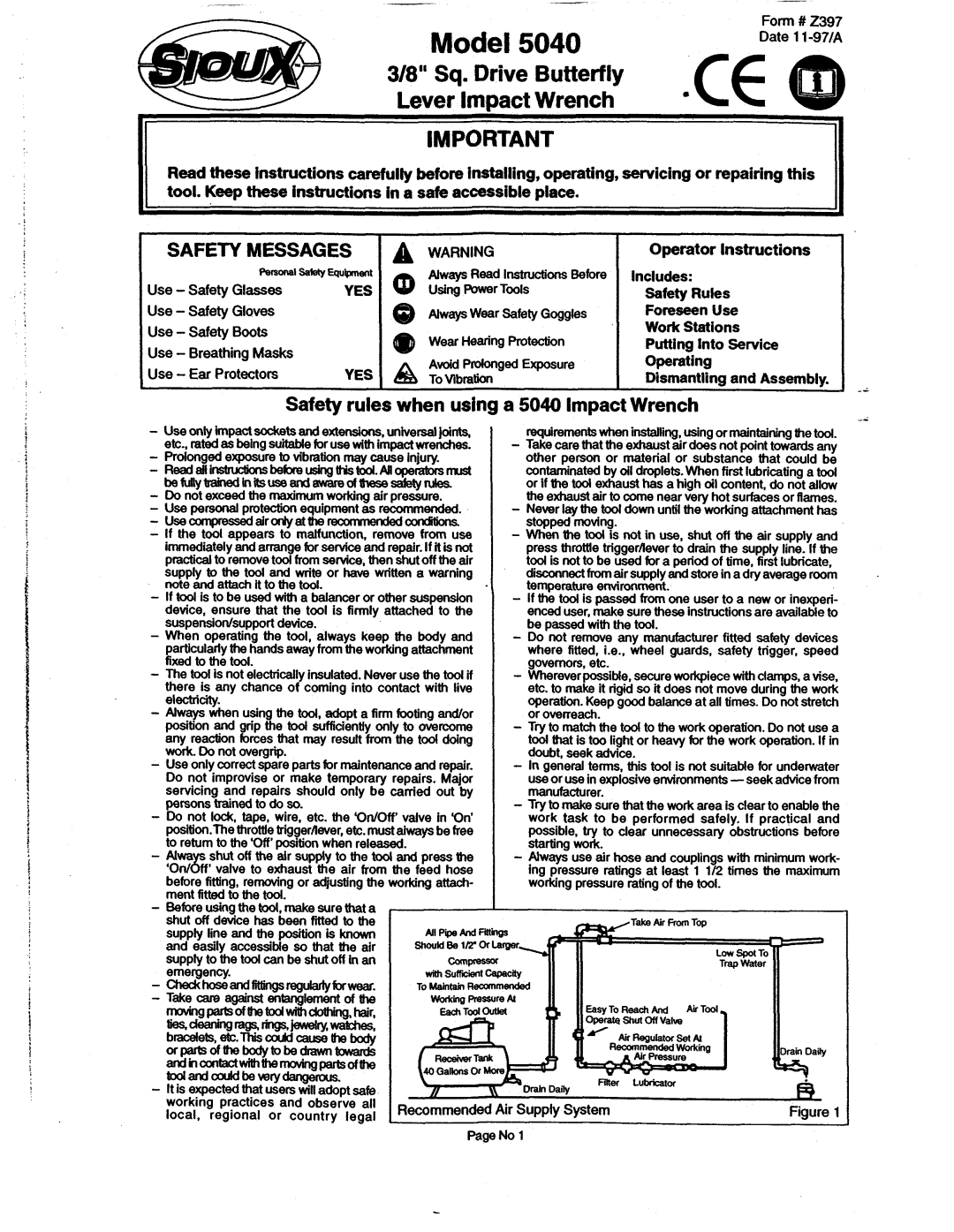

| TakeAir FromTop |

| |||||

supply line and the position is known |

| Ail P i And F i l t i i |

|

| Low Spot To | ||||||

and easily accessible so that the air |

|

|

|

|

| L.2 |

| ||||

|

|

|

|

|

|

|

|

|

|

| |

supply to the t d canbe shutoff inan |

| *W |

|

| Trap Water |

|

| ||||

emergency. |

|

|

|

| wiul s u w icapacity |

|

|

|

| ||

C h e C k ~ a n d ~ r e g ~ f G f To~ Maintain. | U m | W |

|

|

| ||||||

~ & ecare against entang~ementof the |

|

|

|

| Easy To Reach And Air T d |

|

| ||||

nmingpartsofthetcdwihdothing,hair, |

|

|

|

|

|

| |||||

b ~ t s , e t c . T l n s c u d d c a u s e ~ b o d y

orpartsofthcJbodytobedmwntuwa~~~

a n d i n ~ ~ t h e ~ ~ o f t h c J

t o d a n d c c u l d b e w t y ~ |

|

|

Itis expectedthat users will adopt sfe | 1 RecommendedAir Supply System |

|

working practices and observe all | Figure 1 | |

local, regional or country legal | ||

| Page No 1 |

|