SM 1619X04086

surface. Then, simply apply even pressure when driving the screw. The screw shank clearance hole in the first piece allows the screw head to pull the pieces tightly together.

The adjustable screw drill accessory will do all of these oper ations quickly and easily. Screw drills are available for screw sizes No. 6, 8, 10 and 12.

DRILL BITS

Always inspect drill bits for excessive wear. Use only bits that are sharp and in good condition.

TWIST BITS: Available with straight and reduced shanks for wood and light duty metal drilling. High speed bits cut faster and last longer on hard ma erialst.

CARBIDE TIPPED BITS: Used for drilling stone, con crete, plaster, cement and other unusually hard nonmetals. Use continuous heavy feed pres sure when employing carbide tip bits.

DRILLING WOOD

Be certain workpiece is clamped or anchored firm yl. Always apply pressure in a straight line with the drill bit. Maintain enough pressure to keep the drill “biting”.

When drilling holes in wood, twist bits can be used. Twist bits may overheat unless pulled out frequently to clear chips from flutes.

Use a

You will drill a cleaner hole if you ease up on the pressure just before the bit breaks through the wood. Then complete the hole from the back side.

DRILLING METAL

There are two rules for drilling hard materials. First, the harder the material, the greater the pres sure you need to apply to the tool. Second, the harder the material, the slower the speed. Here are a couple of tips for drilling in metal. Lubri cate the tip of the bit occasionally with cutting oil except when drilling soft metals such as alu minum, cop per or cast iron. If the hole to be drilled is fairly large, drill a smaller hole first, then enlarge to the required size, it’s often faster in the long run. Main tain enough pressure to assure that the bit does not just spin in the hole. This will dull the bit and greatly shorten its life.

DRILLING MASONRY

Soft materials such as brick are relatively easy to drill. Concrete however, will require much more pressure to keep the bit from spinning. Be sure to use carbide tip bits for all masonry work.

Before using an accessory, ! WARNING be certain that its maximum

safe operating speed is not exceeded by the nameplate speed of the tool. Do not exceed the recommended wheel diameter.

SANDING AND POLISHING

Fine sanding and polishing re quire “touch”. Select the most efficient speed.

When using polishing bonnets, always be sure the excess string that secures the bonnet is tucked well within the bonnet during operation.

WIRE BRUSHES

Work with brushes requires high speeds.

BRUSHING PRESSURE

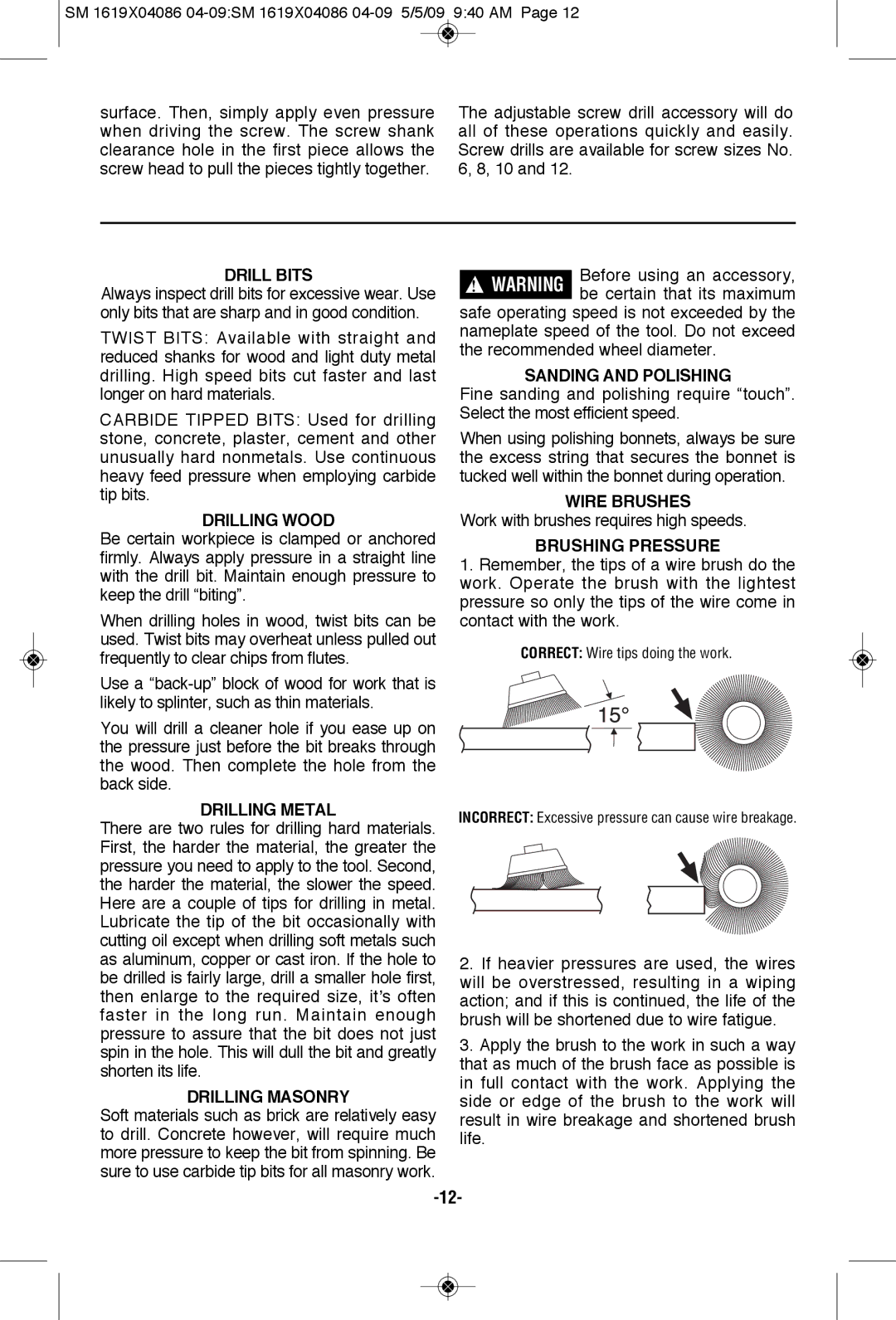

1.Remember, the tips of a wire brush do the work. Operate the brush with the lightest pressure so only the tips of the wire come in contact with the work.

CORRECT: Wire tips doing the work.

INCORRECT: Excessive pressure can cause wire breakage.

2.If heavier pressures are used, the wires will be overstressed, resulting in a wiping action; and if this is continued, the life of the brush will be shortened due to wire fatigue.

3.Apply the brush to the work in such a way that as much of the brush face as possible is in full contact with the work. Applying the side or edge of the brush to the work will result in wire breakage and shortened brush life.