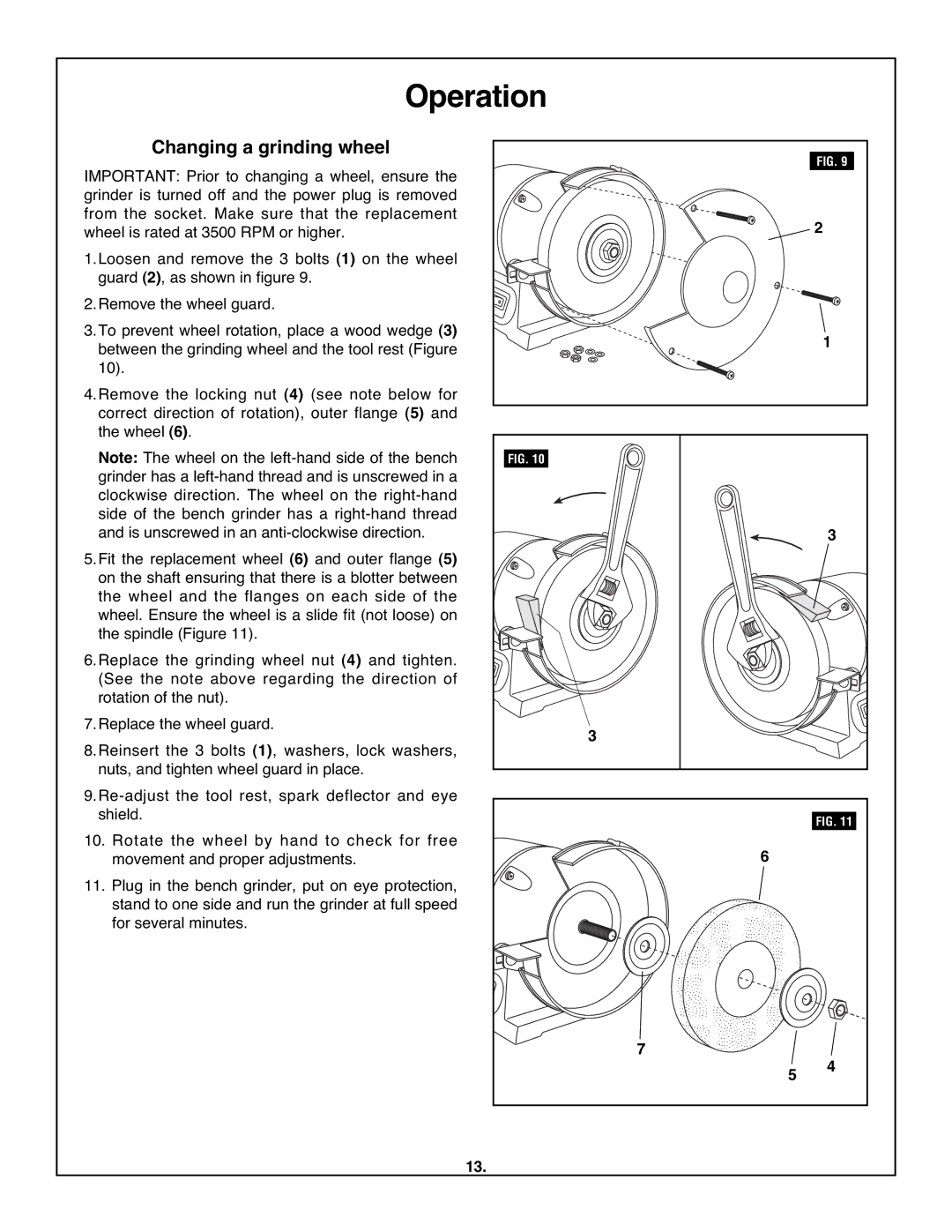

Changing a grinding wheel | Operation |

| FIG. 9 | |

IMPORTANT: Prior to changing a wheel, ensure the |

|

|

| |

grinder is turned off and the power plug is removed |

|

|

| |

from the socket. Make sure that the replacement |

|

| 2 | |

wheel is rated at 3500 RPM or higher. |

|

|

| |

1.Loosen and remove the 3 bolts (1) on the wheel |

|

|

| |

guard (2), as shown in figure 9. |

|

|

|

|

2.Remove the wheel guard. |

|

|

|

|

3.To prevent wheel rotation, place a wood wedge (3) |

|

| 1 | |

between the grinding wheel and the tool rest (Figure |

|

| ||

10). |

|

|

|

|

4.Remove the locking nut (4) (see note below for |

|

|

| |

correct direction of rotation), outer flange | (5) and |

|

|

|

the wheel (6). |

|

|

|

|

Note: The wheel on the | FIG. 10 |

|

| |

grinder has a |

|

|

| |

clockwise direction. The wheel on the |

|

|

| |

side of the bench grinder has a |

|

|

| |

and is unscrewed in an |

|

| 3 | |

5.Fit the replacement wheel (6) and outer flange (5) |

|

| ||

on the shaft ensuring that there is a blotter between |

|

|

| |

the wheel and the flanges on each side of the |

|

|

| |

wheel. Ensure the wheel is a slide fit (not loose) on |

|

|

| |

the spindle (Figure 11). |

|

|

|

|

6.Replace the grinding wheel nut (4) and tighten. |

|

|

| |

(See the note above regarding the direction of |

|

|

| |

rotation of the nut). |

|

|

|

|

7.Replace the wheel guard. |

|

| 3 |

|

8.Reinsert the 3 bolts (1), washers, lock washers, |

|

| ||

nuts, and tighten wheel guard in place. |

|

|

|

|

|

|

| ||

shield. |

|

|

| FIG. 11 |

10. Rotate the wheel by hand to check for free |

| 6 |

| |

movement and proper adjustments. |

|

|

| |

11. Plug in the bench grinder, put on eye protection, |

|

|

| |

stand to one side and run the grinder at full speed |

|

|

| |

for several minutes |

|

|

|

|

7 | 5 | 4 |

|

13.