SM 1619X02967

SM 1619X02967 05-08 4/30/08 11:34 AM Page 13

|

|

| Service | Maintenance | Cleaning | ||||||

|

|

|

|

|

|

|

|

|

| ||

|

| Preventive maintenance |

|

|

|

| To avoid accidents always | ||||

! | WARNING |

| ! | WARNING |

| ||||||

|

| performed by unauthorized |

| disconnect the tool from | |||||||

personnel may result in misplacing of | the power supply before cleaning or | ||||||||||

internal wires and components which | performing any maintenance. The tool may | ||||||||||

could cause serious hazard. | We | be cleaned most effectively with compressed | |||||||||

recommend that all tool service, including | dry air. Always wear safety goggles when | ||||||||||

service of laser, be performed by a Skil | cleaning tools with compressed air. | ||||||||||

Factory Service Center or Authorized Skil | Ventilation openings and switch levers must | ||||||||||

Service Station. |

|

|

|

| be kept clean and free of foreign matter. Do | ||||||

| TOOL LUBRICATION |

|

|

| not attempt to clean by inserting pointed | ||||||

Your Skil tool has been properly lubricated | objects through openings. | ||||||||||

and is ready to use. It is recommended that |

|

|

|

|

| Certain cleaning agents and | |||||

| ! | CAUTION |

|

| |||||||

tools with gears be regreased with a special |

|

| solvents damage plastic | ||||||||

gear lubricant at every brush change. |

|

|

| parts. Some of these are: gasoline, carbon | |||||||

| CARBON BRUSHES |

|

|

| tetrachloride, chlorinated cleaning solvents, | ||||||

The brushes and commutator in your tool | ammonia and household detergents that | ||||||||||

have been engineered for many hours of | contain ammonia. | ||||||||||

dependable service. To maintain peak |

| CARE OF BLADES | |||||||||

efficiency of the motor, we recommend every | Blades become dull even from cutting regular | ||||||||||

two to six months the brushes be examined. | lumber. If you find yourself forcing the saw | ||||||||||

Only genuine Skil replacement brushes | forward to cut instead of just guiding it through | ||||||||||

specially designed for your tool should be | the cut, chances are the blade is dull or coated | ||||||||||

used. | BEARINGS |

|

|

| with wood pitch. |

| |||||

|

|

|

|

|

| When cleaning gum and wood pitch from | |||||

After about | blade, unplug the saw and remove the blade. | ||||||||||

every second brush change, the bearings | Remember, blades are designed to cut, so | ||||||||||

should be replaced at Skil Factory Service | handle carefully. Wipe the blade with kerosene | ||||||||||

Center or Authorized Skil Service Station. | or similar solvent to remove the gum and pitch. | ||||||||||

Bearings which become noisy (due to heavy | Unless you are experienced in sharpening | ||||||||||

load or very abrasive material cutting) should | blades, we recommend you do not try. | ||||||||||

be replaced at once to avoid overheating or | |||||||||||

motor failure. |

|

|

|

|

|

|

|

|

| ||

|

| Accessories |

|

|

|

|

|

|

|

| |

|

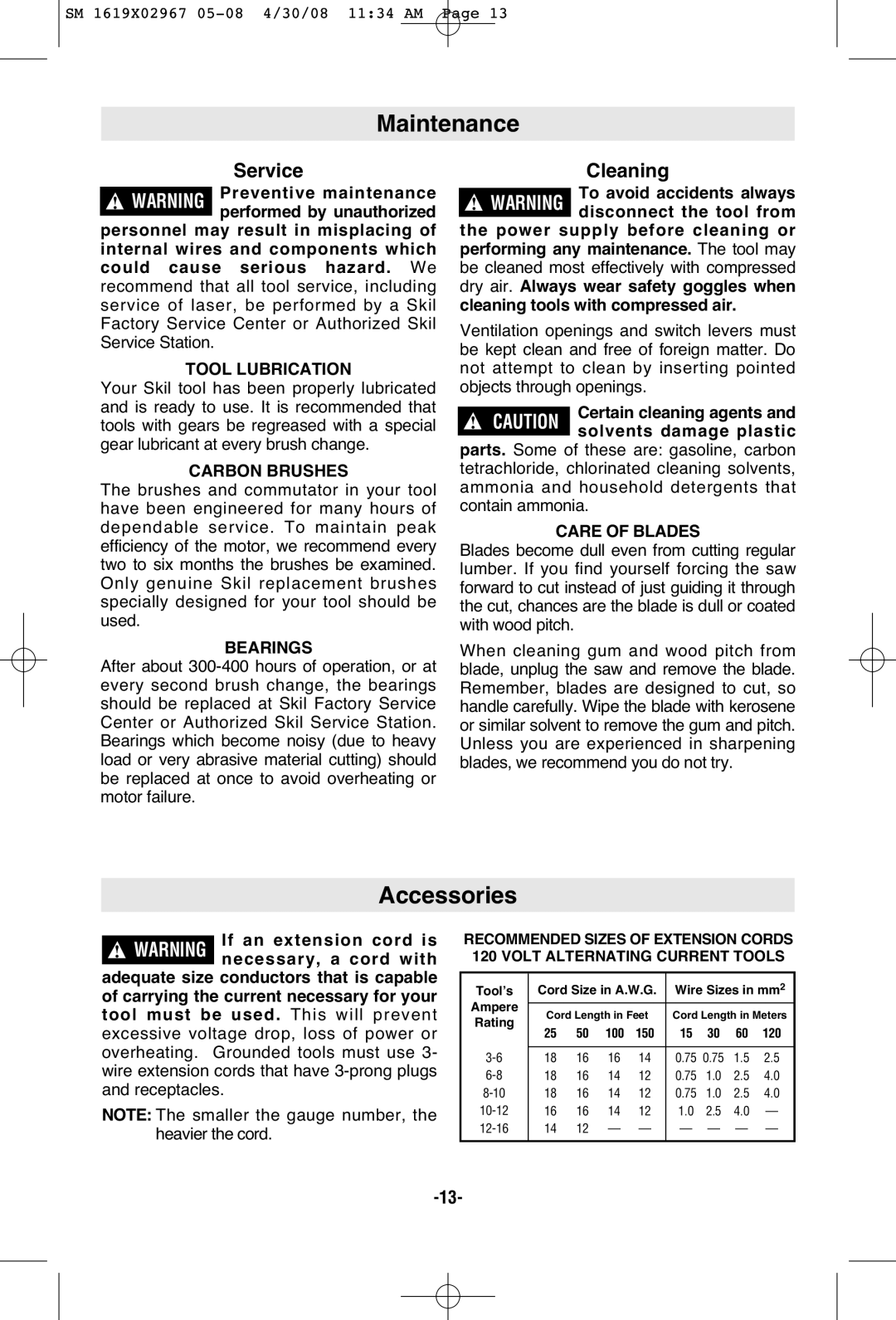

| If an extension cord is | RECOMMENDED SIZES OF EXTENSION CORDS | ||||||||

! | WARNING | ||||||||||

| necessary, a cord with | 120 VOLT ALTERNATING CURRENT TOOLS | |||||||||

adequate size conductors that is capable |

|

|

|

|

|

|

|

|

| ||

Tool’s | Cord Size in A.W.G. |

|

|

| 2 | ||||||

of carrying the current necessary for your | Wire Sizes in mm | ||||||||||

tool must be used. This will prevent | Ampere | Cord Length in Feet | Cord Length in Meters | ||||||||

excessive voltage drop, loss of power or | Rating | 25 | 50 | 100 | 150 | 15 | 30 | 60 | 120 | ||

overheating. | Grounded tools must use 3- |

|

|

|

|

|

|

|

| ||

18 | 16 | 16 | 14 | 0.75 | 0.75 | 1.5 | 2.5 | ||||

wire extension cords that have | 18 | 16 | 14 | 12 | 0.75 | 1.0 | 2.5 | 4.0 | |||

and receptacles. | 18 | 16 | 14 | 12 | 0.75 | 1.0 | 2.5 | 4.0 | |||

NOTE: The smaller the gauge number, the | 14 | 12 | — | — | — | — | — | — | |||

| heavier the cord. | 16 | 16 | 14 | 12 | 1.0 | 2.5 | 4.0 | — | ||

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|