Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

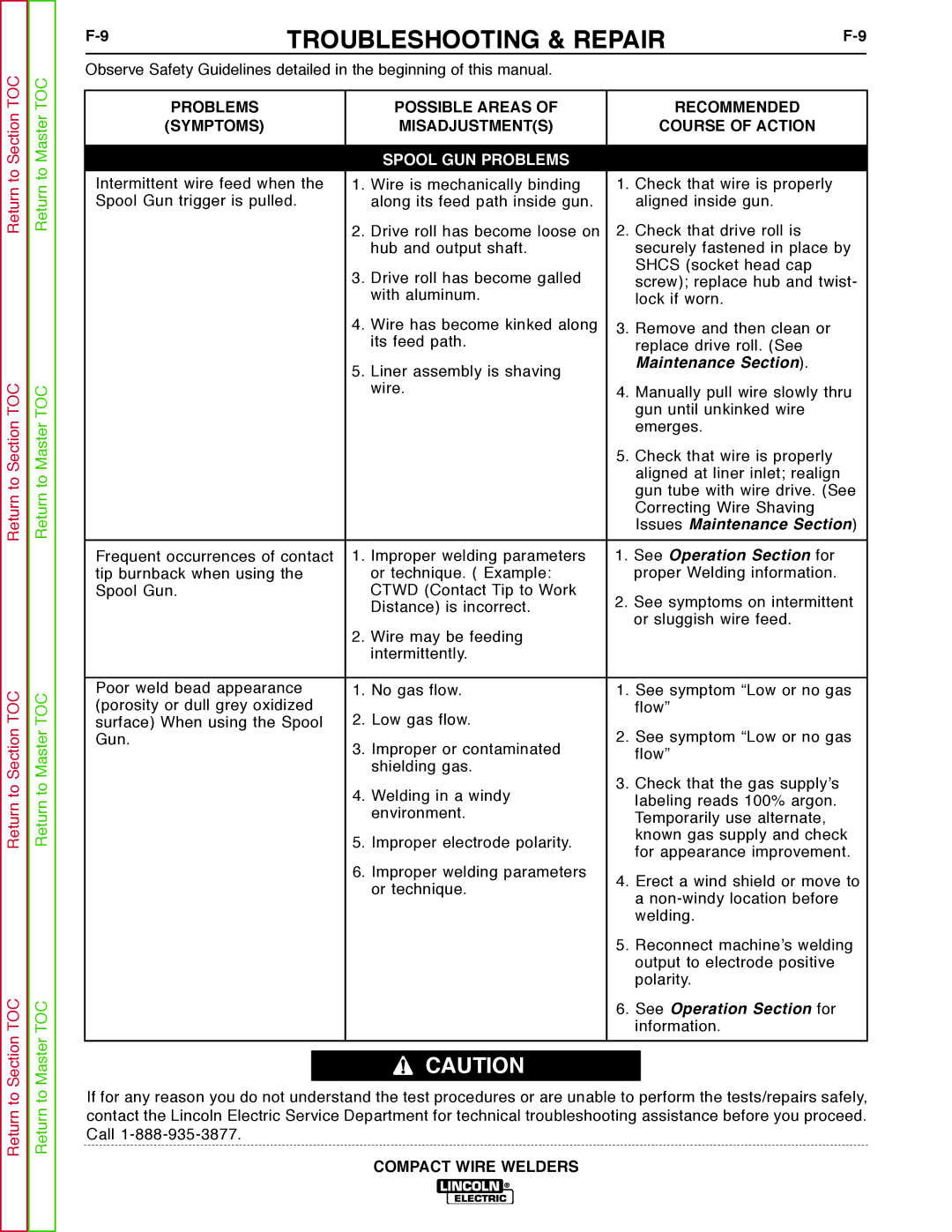

TROUBLESHOOTING & REPAIR | ||||

|

|

| ||

|

|

| ||

Observe Safety Guidelines detailed in the beginning of this manual. |

|

| ||

|

|

|

|

|

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

|

|

|

|

| SPOOL GUN PROBLEMS |

|

|

Intermittent wire feed when the | 1. Wire is mechanically binding | 1. Check that wire is properly |

| |

Spool Gun trigger is pulled. | along its feed path inside gun. | aligned inside gun. |

| |

|

| 2. Drive roll has become loose on | 2. Check that drive roll is |

|

|

| hub and output shaft. | securely fastened in place by | |

|

| 3. Drive roll has become galled | SHCS (socket head cap |

|

|

| screw); replace hub and twist- | ||

|

| with aluminum. | ||

|

| lock if worn. |

| |

|

|

|

| |

|

| 4. Wire has become kinked along | 3. Remove and then clean or |

|

|

| its feed path. |

| |

|

| replace drive roll. (See |

| |

|

|

|

| |

|

| 5. Liner assembly is shaving | Maintenance Section). |

|

|

|

|

| |

|

| wire. | 4. Manually pull wire slowly thru | |

|

|

| ||

|

|

| gun until unkinked wire |

|

|

|

| emerges. |

|

|

|

| 5. Check that wire is properly |

|

|

|

| aligned at liner inlet; realign |

|

|

|

| gun tube with wire drive. (See | |

|

|

| Correcting Wire Shaving |

|

|

|

| Issues Maintenance Section) | |

|

|

|

| |

Frequent occurrences of contact | 1. Improper welding parameters | 1. See Operation Section for |

| |

tip burnback when using the | or technique. ( Example: | proper Welding information. |

| |

Spool Gun. |

| CTWD (Contact Tip to Work | 2. See symptoms on intermittent | |

|

| Distance) is incorrect. | ||

|

| or sluggish wire feed. |

| |

|

|

|

| |

|

| 2. Wire may be feeding |

|

|

|

| intermittently. |

|

|

|

|

| ||

Poor weld bead appearance | 1. No gas flow. | 1. See symptom “Low or no gas | ||

(porosity or dull grey oxidized | 2. Low gas flow. | flow” |

| |

surface) When using the Spool | 2. See symptom “Low or no gas | |||

Gun. |

| 3. Improper or contaminated | ||

|

| flow” |

| |

|

| shielding gas. |

| |

|

|

|

| |

|

| 4. Welding in a windy | 3. Check that the gas supply’s |

|

|

| labeling reads 100% argon. |

| |

|

| environment. |

| |

|

| Temporarily use alternate, |

| |

|

|

|

| |

|

| 5. Improper electrode polarity. | known gas supply and check | |

|

| for appearance improvement. | ||

|

|

| ||

|

| 6. Improper welding parameters | 4. Erect a wind shield or move to | |

|

| or technique. | ||

|

| a |

| |

|

|

|

| |

|

|

| welding. |

|

|

|

| 5. Reconnect machine’s welding | |

|

|

| output to electrode positive |

|

|

|

| polarity. |

|

|

|

| 6. See Operation Section for |

|

|

|

| information. |

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call