TOC

TOC

| INSTALLATION |

| |||

|

|

|

| ||

|

|

|

|

| |

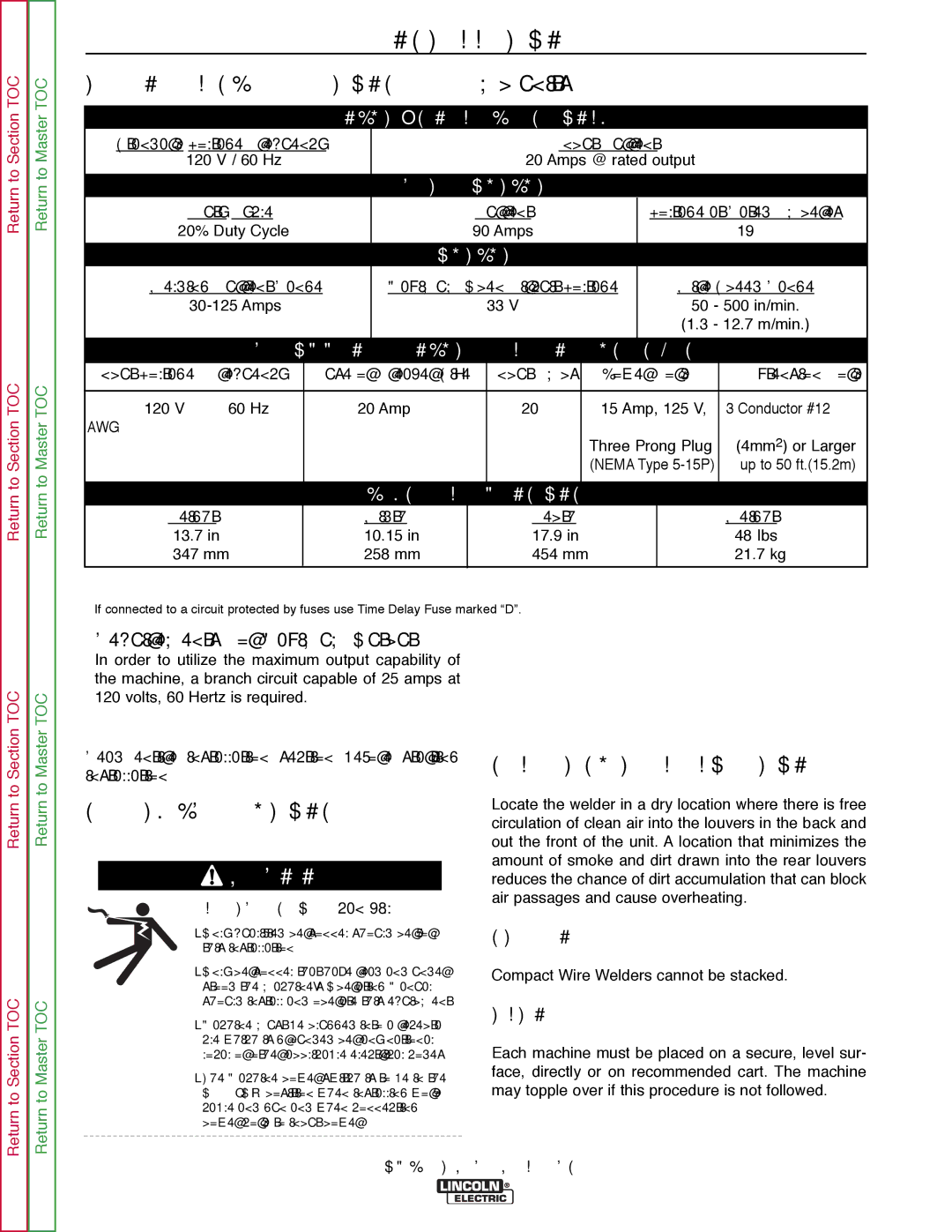

| TECHNICAL SPECIFICATIONS | 125 Amp units |

|

| |

|

|

|

|

| |

|

| INPUT – SINGLE PHASE ONLY |

|

| |

to Section

to Master

Standard Voltage/Frequency

120 V / 60 Hz

Input Current

20 Amps @ rated output

Return

Return

Duty Cycle

20% Duty Cycle

Welding Current Range

RATED OUTPUT

Current

90 Amps

OUTPUT

33 V

Voltage at Rated Amperes

19

Wire Speed Range

50 - 500 in/min.

(1.3 - 12.7 m/min.)

Return to Section TOC

Return to Master TOC

| RECOMMENDED INPUT CABLE AND FUSE SIZES |

| ||||||

Input Voltage / Frequency | Fuse or Breaker Size1,2 | Input Amps |

| Power Cord | Extension Cord | |||

|

|

|

|

|

|

|

|

|

120 V | 60 Hz | 20 Amp | 20 |

| 15 Amp, 125 V, | 3 Conductor #12 | ||

AWG |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Three Prong Plug | (4mm2) or Larger | |

|

|

|

|

|

| (NEMA Type | up to 50 ft.(15.2m) | |

|

|

|

|

|

|

|

|

|

|

| PHYSICAL DIMENSIONS |

|

|

| |||

|

|

|

|

|

|

|

| |

Height |

| Width |

| Depth |

|

| Weight | |

13.7 in |

| 10.15 in |

| 17.9 in |

|

| 48 Ibs | |

347 mm | 258 mm |

| 454 mm |

|

| 21.7 kg | ||

|

|

|

|

|

|

|

|

|

1If connected to a circuit protected by fuses use Time Delay Fuse marked “D”.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

2Requirements For Maximum Output

In order to utilize the maximum output capability of the machine, a branch circuit capable of 25 amps at 120 volts, 60 Hertz is required.

Read entire installation section before starting installation.

SAFETY PRECAUTIONS

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

•Only qualified personnel should perform this installation.

•Only personnel that have read and under- stood the machine’s Operating Manual should install and operate this equipment.

•Machine must be plugged into a recepta- cle which is grounded per any national, local or other applicable electrical codes.

•The Machine power switch is to be in the OFF (“O”) position when installing work cable and gun and when connecting power cord to input power.

SELECT SUITABLE LOCATION

Locate the welder in a dry location where there is free circulation of clean air into the louvers in the back and out the front of the unit. A location that minimizes the amount of smoke and dirt drawn into the rear louvers reduces the chance of dirt accumulation that can block air passages and cause overheating.

STACKING

Compact Wire Welders cannot be stacked.

TILTING

Each machine must be placed on a secure, level sur- face, directly or on recommended cart. The machine may topple over if this procedure is not followed.

COMPACT WIRE WELDERS