TOC

TOC

B-11 OPERATION

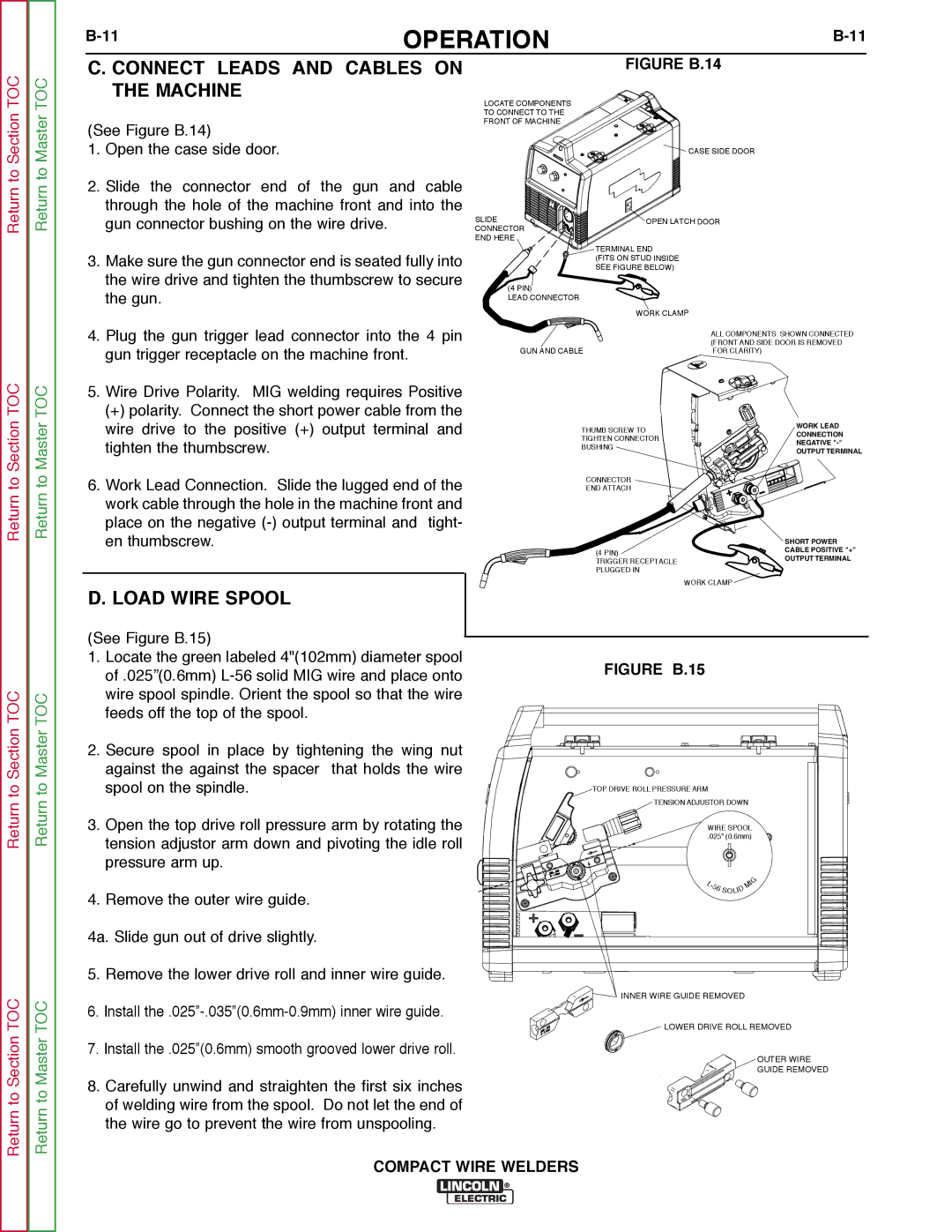

C. CONNECT LEADS AND CABLES ON THE MACHINE

FIGURE B.14

Section

Master

(See Figure B.14)

LOCATE COMPONENTS TO CONNECT TO THE FRONT OF MACHINE

1.Open the case side door.

2.Slide the connector end of the gun and cable

through the hole of the machine front and into the

gun connector bushing on the wire drive. | SLIDE | |

CONNECTOR | ||

| END HERE | |

3. Make sure the gun connector end is seated fully into |

| |

the wire drive and tighten the thumbscrew to secure | (4 PIN) | |

the gun. | ||

LEAD CONNECTOR | ||

|

![]() CASE SIDE DOOR

CASE SIDE DOOR

OPEN LATCH DOOR

TERMINAL END (FITS ON STUD INSIDE SEE FIGURE BELOW)

WORK CLAMP

4. Plug the gun trigger lead connector into the 4 pin |

| ALL COMPONENTS SHOWN CONNECTED |

| GUN AND CABLE | (FRONT AND SIDE DOOR IS REMOVED |

gun trigger receptacle on the machine front. | FOR CLARITY) | |

|

|

TOC

TOC

5. Wire Drive Polarity. MIG welding requires Positive |

(+) polarity. Connect the short power cable from the |

wire drive to the positive (+) output terminal and |

THUMB SCREW TO

WORK LEAD CONNECTION

TIGHTEN CONNECTOR

BUSHING

NEGATIVE

OUTPUT TERMINAL

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

tighten the thumbscrew. |

6. Work Lead Connection. Slide the lugged end of the |

work cable through the hole in the machine front and |

place on the negative |

en thumbscrew. |

D. LOAD WIRE SPOOL

(See Figure B.15)

1.Locate the green labeled 4"(102mm) diameter spool of .025”(0.6mm)

2.Secure spool in place by tightening the wing nut against the against the spacer that holds the wire spool on the spindle.

3.Open the top drive roll pressure arm by rotating the tension adjustor arm down and pivoting the idle roll pressure arm up.

4.Remove the outer wire guide.

CONNECTOR |

| |

END ATTACH |

| |

| SHORT POWER | |

(4 PIN) | CABLE POSITIVE "+" | |

OUTPUT TERMINAL | ||

TRIGGER RECEPTACLE | ||

| ||

PLUGGED IN |

| |

| WORK CLAMP |

FIGURE B.15

TOP DRIVE ROLL PRESSURE ARM

![]() TENSION ADJUSTOR DOWN

TENSION ADJUSTOR DOWN

WIRE SPOOL

.025" (0.6mm)

L |

|

|

| IG |

- |

|

| M | |

| 5 | 6 |

| |

|

| D | ||

|

|

| S OLI |

|

Return to Section TOC

Return to Master TOC

4a. Slide gun out of drive slightly.

5. Remove the lower drive roll and inner wire guide.

![]() INNER WIRE GUIDE REMOVED

INNER WIRE GUIDE REMOVED

6. Install

LOWER DRIVE ROLL REMOVED

7. Install the .025”(0.6mm) smooth grooved lower drive roll.

OUTER WIRE

GUIDE REMOVED

8. Carefully unwind and straighten the first six inches of welding wire from the spool. Do not let the end of the wire go to prevent the wire from unspooling.

COMPACT WIRE WELDERS