B-12 OPERATION

Return to Master TOC

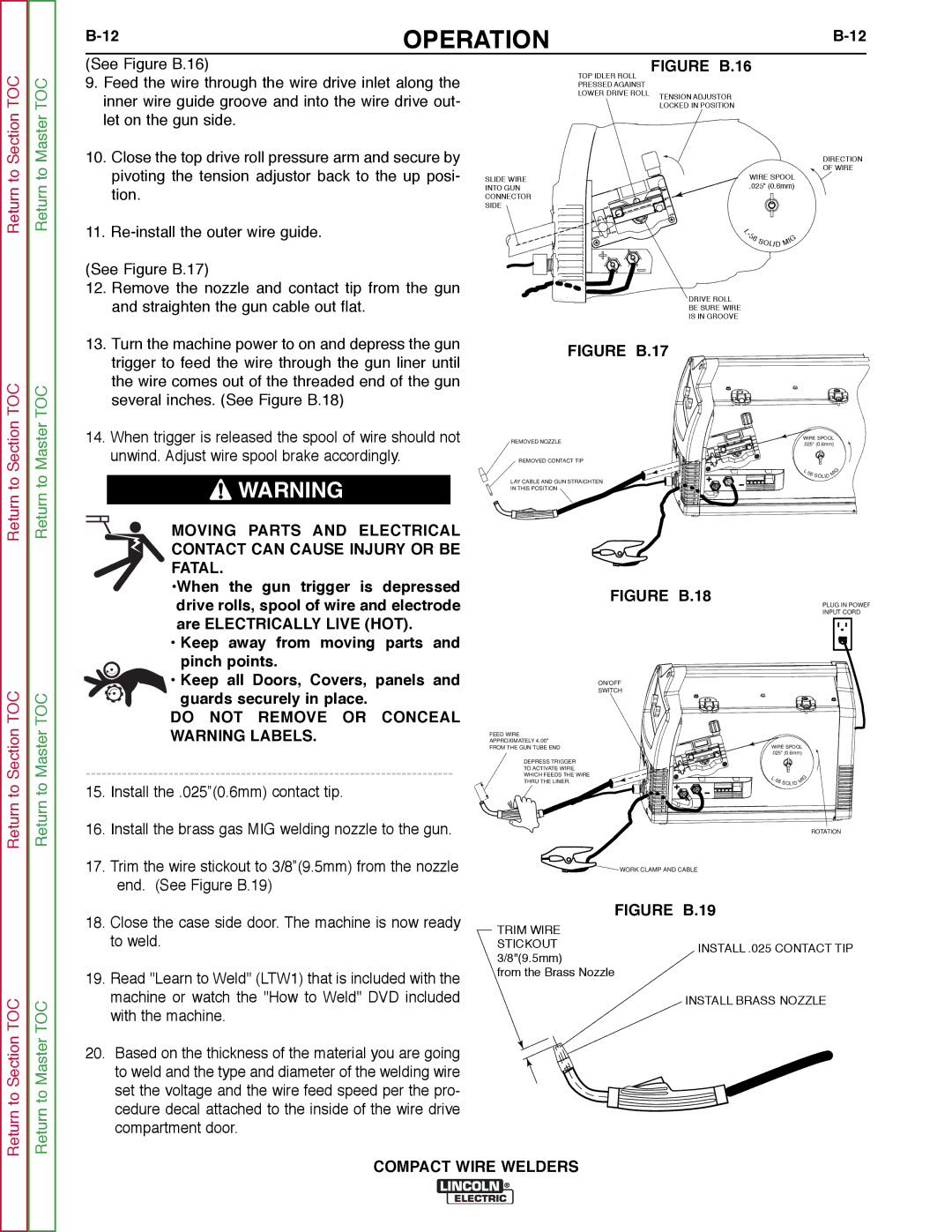

(See Figure B.16)

9.Feed the wire through the wire drive inlet along the inner wire guide groove and into the wire drive out- let on the gun side.

10.Close the top drive roll pressure arm and secure by pivoting the tension adjustor back to the up posi- tion.

11.

(See Figure B.17)

12.Remove the nozzle and contact tip from the gun and straighten the gun cable out flat.

SLIDE WIRE INTO GUN CONNECTOR SIDE

FIGURE B.16

TOP IDLER ROLL

PRESSED AGAINST

LOWER DRIVE ROLL TENSION ADJUSTOR

LOCKED IN POSITION

DIRECTION OF WIRE

WIRE SPOOL

.025" (0.6mm)

L |

|

- |

|

5 |

|

6 | IG |

| S |

| OLI DM |

DRIVE ROLL

BE SURE WIRE

IS IN GROOVE

Return to Master TOC

13.Turn the machine power to on and depress the gun trigger to feed the wire through the gun liner until the wire comes out of the threaded end of the gun several inches. (See Figure B.18)

14.When trigger is released the spool of wire should not unwind. Adjust wire spool brake accordingly.

![]() WARNING

WARNING

MOVING PARTS AND ELECTRICAL CONTACT CAN CAUSE INJURY OR BE FATAL.

FIGURE B.17

REMOVED NOZZLE

REMOVED CONTACT TIP

LAY CABLE AND GUN STRAIGHTEN

IN THIS POSITION

WIRE SPOOL

.025" (0.6mm)

L |

| IG |

6 | ||

| SOLIDM |

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

•When the gun trigger is depressed drive rolls, spool of wire and electrode are ELECTRICALLY LIVE (HOT).

•Keep away from moving parts and pinch points.

•Keep all Doors, Covers, panels and

guards securely in place.

DO NOT REMOVE OR CONCEAL WARNING LABELS.

15. Install the .025”(0.6mm) contact tip. |

16. Install the brass gas MIG welding nozzle to the gun. |

17. Trim the wire stickout to 3/8”(9.5mm) from the nozzle |

end. (See Figure B.19) |

FIGURE B.18

ON/OFF

SWITCH

FEED WIRE

APPROXIMATELY 4.00"

FROM THE GUN TUBE END

DEPRESS TRIGGER

TO ACTIVATE WIRE,

WHICH FEEDS THE WIRE

THRU THE LINER.

![]() WORK CLAMP AND CABLE

WORK CLAMP AND CABLE

PLUG IN POWER

INPUT CORD

WIRE SPOOL

.025" (0.6mm)

L |

| IG |

6 | ||

| SOLIDM |

ROTATION

Return to Section TOC

Return to Master TOC

18. | Close the case side door. The machine is now ready |

| to weld. |

19. | Read "Learn to Weld" (LTW1) that is included with the |

| machine or watch the "How to Weld" DVD included |

| with the machine. |

20. | Based on the thickness of the material you are going |

| to weld and the type and diameter of the welding wire |

| set the voltage and the wire feed speed per the pro- |

| cedure decal attached to the inside of the wire drive |

| compartment door. |

FIGURE B.19

TRIM WIRE

STICKOUTINSTALL .025 CONTACT TIP 3/8"(9.5mm)

from the Brass Nozzle

INSTALL BRASS NOZZLE

COMPACT WIRE WELDERS