Assembly

Preparing the Saw

BLADE SELECTION

No one blade can be efficient on all cutting jobs. Different materials require specially designed blades. Since your reciprocating saw can cut so many materials, many types of SKIL blades are available. Be sure to use the proper blade to insure proper cutting performance.

INSTALLING A BLADE

!WARNING Unplug tool from power source before changing blade

or making any adjustments.

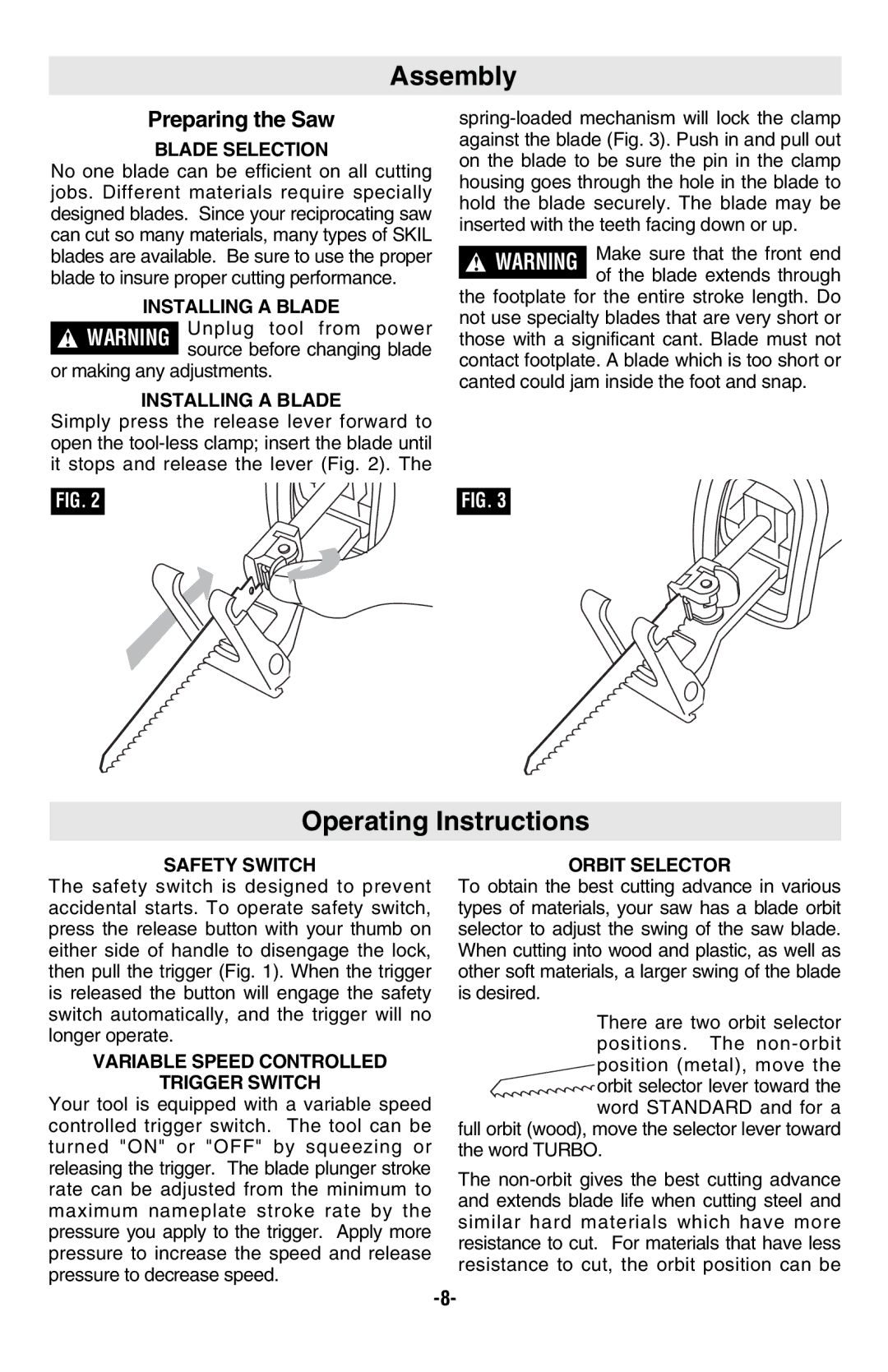

INSTALLING A BLADE

Simply press the release lever forward to open the

!WARNING Make sure that the front end of the blade extends through

the footplate for the entire stroke length. Do not use specialty blades that are very short or those with a significant cant. Blade must not contact footplate. A blade which is too short or canted could jam inside the foot and snap.

FIG. 2 | FIG. 3 |

Operating Instructions

SAFETY SWITCH

The safety switch is designed to prevent accidental starts. To operate safety switch, press the release button with your thumb on either side of handle to disengage the lock, then pull the trigger (Fig. 1). When the trigger is released the button will engage the safety switch automatically, and the trigger will no longer operate.

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed controlled trigger switch. The tool can be turned "ON" or "OFF" by squeezing or releasing the trigger. The blade plunger stroke rate can be adjusted from the minimum to maximum nameplate stroke rate by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed.

ORBIT SELECTOR

To obtain the best cutting advance in various types of materials, your saw has a blade orbit selector to adjust the swing of the saw blade. When cutting into wood and plastic, as well as other soft materials, a larger swing of the blade is desired.

There are two orbit selector

positions. The

position (metal), move the

![]()

![]()

![]() orbit selector lever toward the

orbit selector lever toward the ![]() word STANDARD and for a full orbit (wood), move the selector lever toward

word STANDARD and for a full orbit (wood), move the selector lever toward

the word TURBO.

The