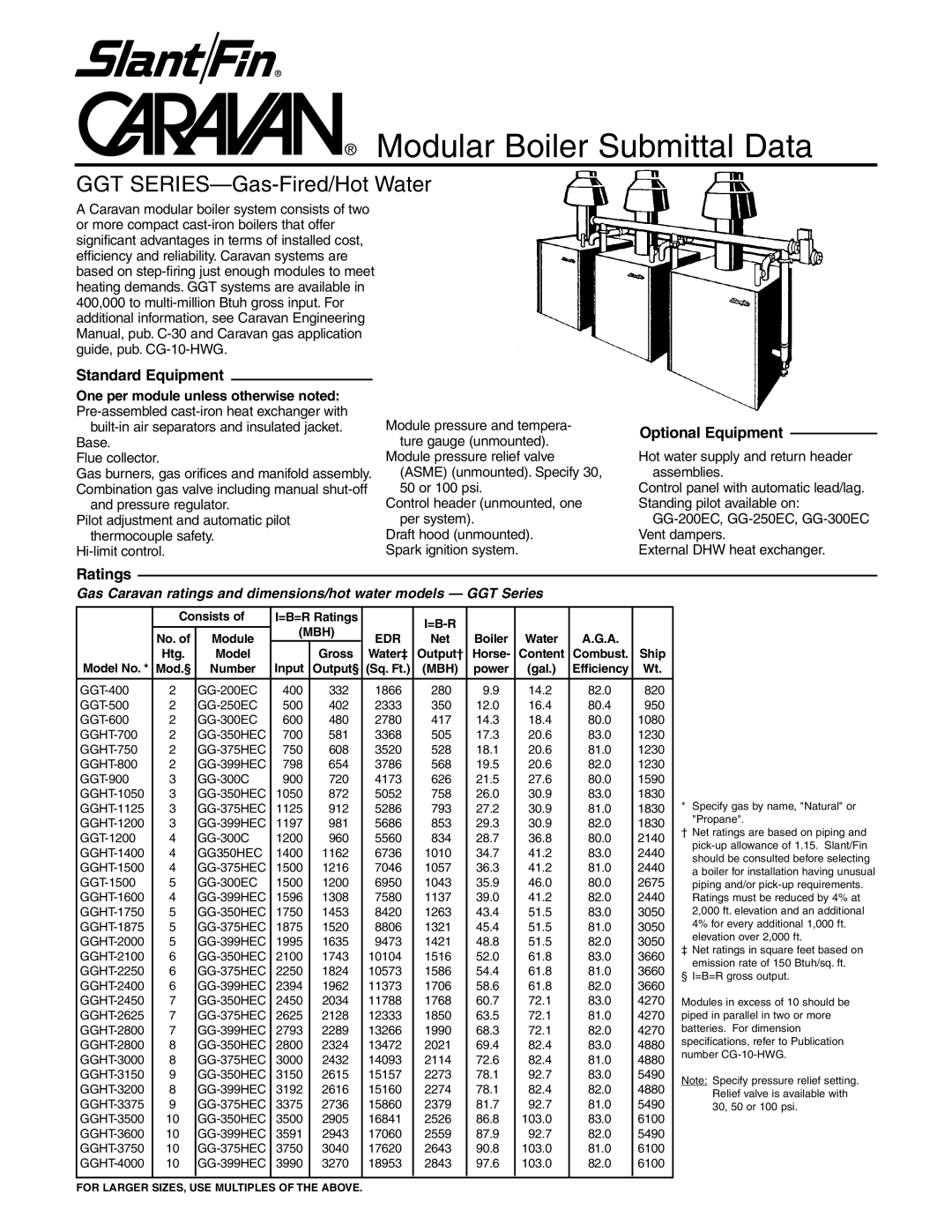

GGT Series specifications

The Slant/Fin GGT Series is a groundbreaking line of high-efficiency condensing gas boilers designed to meet the growing demands for reliability, performance, and energy efficiency in heating systems. One of the standout features of the GGT Series is its advanced condensing technology, which allows for optimal heat extraction from combustion gases. This design significantly enhances efficiency, translating to lower energy bills for homeowners and reduced environmental impact.A hallmark of the GGT Series is its impressive AFUE (annual fuel utilization efficiency) rating of up to 95%, allowing users to maximize their fuel use while minimizing waste. This efficiency is achieved through a unique design that captures and utilizes heat that would otherwise be lost in traditional boiler systems. The two-stage burner not only provides precise control over heating output but also ensures quieter operation and lower emissions.

The GGT Series is constructed with durable stainless steel heat exchangers, which offer superior resistance to corrosion, leading to a longer lifespan and reduced maintenance needs. The units come equipped with an integrated control system that simplifies user interaction. This advanced control technology allows for easy programming and monitoring, enabling homeowners to manage their heating systems effortlessly. The intuitive interface ensures that users can adjust their heating needs based on personal preferences and comfort levels.

Safety is a top priority for the GGT Series; hence, these boilers are equipped with various safety features, including a high-limit control and flame monitoring system. The units also offer a venting flexibility with options for direct venting or through the roof, making installation adaptable to various home designs and building codes.

Another key characteristic of the GGT Series is its compact design, which allows for easy installation in tight spaces. With models available for both residential and light commercial applications, the GGT Series accommodates a wide range of heating needs, ensuring effective warmth for almost any setting.

In summary, the Slant/Fin GGT Series offers cutting-edge technology, robust construction, and exceptional efficiency, making it an ideal choice for homeowners and businesses looking for a high-performance heating solution. With its combination of advanced features and user-friendly controls, the GGT Series is a sensible and sustainable choice in today’s heating market.