Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance, service or repairs with the engine running. STOP engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine.

4.1ENGINE ADJUSTMENTS & REPAIR

Refer to the Engine owner’s Manual for the adjustments/repairs that can be made by the owner.

4.2MOWER BLADE REPLACEMENT

4.2.1. Blade Wear Limits

Blades are subject to wear during normal usage and require frequent inspections. Blades that have reached the wear limit (see Figure 4.1) or have been damaged must be replaced.

WARNING

DO NOT operate machine with a blade that shows signs of excessive wear or damage.

NEW BLADE![]()

![]() WEAR LIMIT (NOTCH STARTS)

WEAR LIMIT (NOTCH STARTS)

![]() DANGEROUS CONDITION!

DANGEROUS CONDITION!

DO NOT USE ON MOWER!

REPLACE WITH NEW

FIGURE 4.1

4.2.2. Blade Sharpening

Inspect blades carefully. Blades that have not reached the wear limit and have not been damaged may have the cutting edge resharpened. DO NOT attempt to sharpen a blade that shows signs of excessive wear or damage. DO NOT sharpen beyond existing cutting edge.

2.Carefully stand machine on rear bumper.

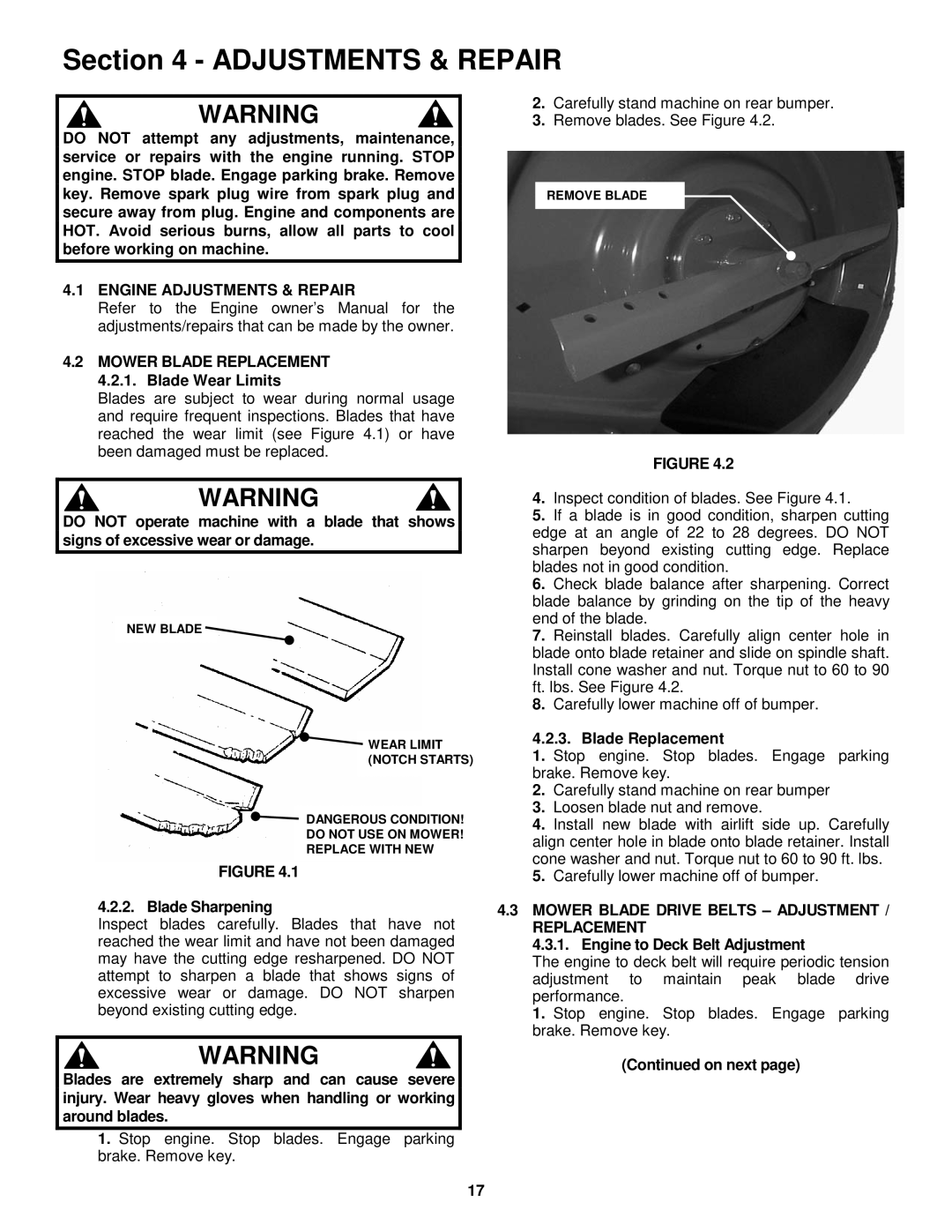

3.Remove blades. See Figure 4.2.

REMOVE BLADE

NUT

FIGURE 4.2

4.Inspect condition of blades. See Figure 4.1.

5.If a blade is in good condition, sharpen cutting edge at an angle of 22 to 28 degrees. DO NOT sharpen beyond existing cutting edge. Replace blades not in good condition.

6.Check blade balance after sharpening. Correct blade balance by grinding on the tip of the heavy end of the blade.

7.Reinstall blades. Carefully align center hole in blade onto blade retainer and slide on spindle shaft. Install cone washer and nut. Torque nut to 60 to 90 ft. lbs. See Figure 4.2.

8.Carefully lower machine off of bumper.

4.2.3. Blade Replacement

1.Stop engine. Stop blades. Engage parking brake. Remove key.

2.Carefully stand machine on rear bumper

3.Loosen blade nut and remove.

4.Install new blade with airlift side up. Carefully align center hole in blade onto blade retainer. Install cone washer and nut. Torque nut to 60 to 90 ft. lbs.

5.Carefully lower machine off of bumper.

4.3MOWER BLADE DRIVE BELTS – ADJUSTMENT / REPLACEMENT

4.3.1.Engine to Deck Belt Adjustment

The engine to deck belt will require periodic tension adjustment to maintain peak blade drive performance.

1.Stop engine. Stop blades. Engage parking brake. Remove key.

WARNING

Blades are extremely sharp and can cause severe injury. Wear heavy gloves when handling or working around blades.

1.Stop engine. Stop blades. Engage parking brake. Remove key.

(Continued on next page)

17