Section 3 – MAINTENANCE

3.2SERVICE - AFTER FIRST 5 HOURS INTERLOCK SYSTEM SAFETY CHECKS (Cont.)

ENGINE MUST NOT START IF:

1)Clutch/brake pedal is not fully depressed OR,

2)Blade Control is in the “ON” (blades engaged) position.

ENGINE SHOULD START IF:

1)Blade Control is in the “OFF” (blades disengaged) position AND,

2)Clutch/brake pedal is fully depressed.

ENGINE AND BLADES MUST STOP IF:

1)Operator rises off of seat with Blade Control in “ON” (blades engaged) position OR,

2)Operator rises off of seat with Clutch/Brake not fully depressed.

3.2.8.REVERSE LOCKOUT MECHANISM Check function of Reverse Lockout Mechanism with engine off.

1. Depress and hold blade pedals.

2. Depress and hold clutch/brake pedal.

3. Shift lever must not go into reverse.

WARNING

DO NOT operate machine if Reverse Lockout Mechanism is not functioning properly. Contact your SNAPPER dealer immediately for assistance.

3.2.9.LUBRICATION – GREASE FITTINGS The following components on the Rear Engine Rider are equipped with grease fittings and require periodic lubrication. Apply General Purpose grease (NLGI No.2) with a grease gun.

1.Front Wheel Bearings. Refer to Section

“FRONT WHEEL BEARINGS – LUBRICATION”.

2.Rear Axle Bearing. Refer to Section “REAR

AXLE BEARING – LUBRICATION”.

3.Mower Blade Spindle. Refer to Section

“MOWER BLADE SPINDLE – LUBRICATION”.

4.Shift Lever. Refer to Section “SHIFT LEVER –

LUBRICATION”.

3.3SERVICE - EVERY 25 OPERATING HOURS

3.3.1.Perform all service required after the first 5 hours of operation. Refer to Section “SERVICE – AFTER 5 HOURS”.

WARNING

DO NOT attempt any adjustments, maintenance, service or repairs with the engine running. Stop engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. Fuel Filler Cap and Vent must be closed securely to prevent fuel spillage.

3.3.1. CHECK ENGINE

1. Engine Cooling System

The engine cooling system consists of an engine shroud and engine fins. These should be kept clean and free of debris as needed or cleaned.

2. Engine Oil

Change engine oil. See Section on CHANGE ENGINE OIL. Refer to engine owner’s manual for oil specifications.

3. Oil Filter

Change engine oil filter. Refer to engine owner’s manual for filter specifications.

4. Fuel Filter

Refer to engine owner’s manual for service instructions.

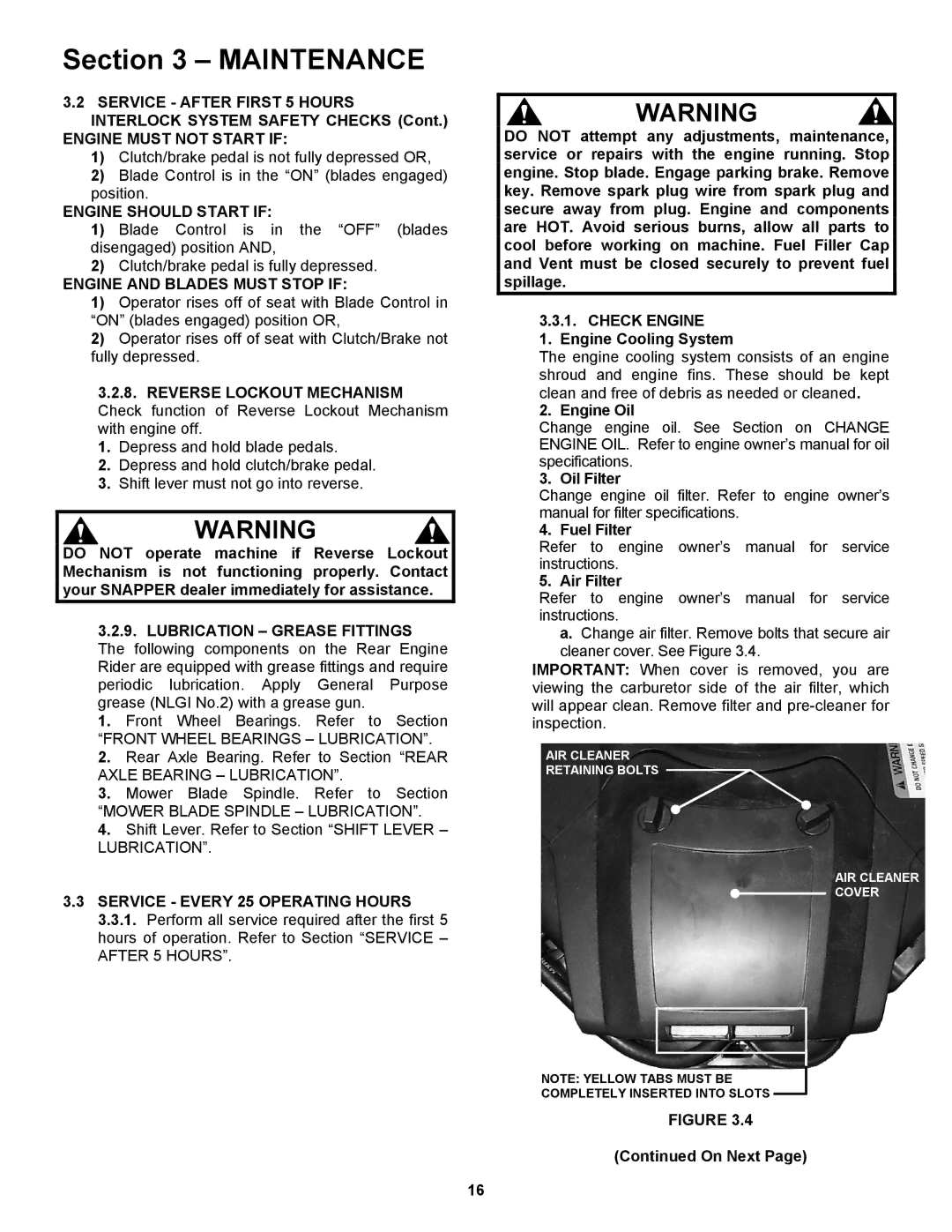

5. Air Filter

Refer to engine owner’s manual for service instructions.

a.Change air filter. Remove bolts that secure air cleaner cover. See Figure 3.4.

IMPORTANT: When cover is removed, you are viewing the carburetor side of the air filter, which will appear clean. Remove filter and

AIR CLEANER

RETAINING BOLTS

AIR CLEANER

![]() COVER

COVER

NOTE: YELLOW TABS MUST BE

COMPLETELY INSERTED INTO SLOTS

FIGURE 3.4

(Continued On Next Page)

16