Section 2 - OPERATING INSTRUCTIONS

2.1PRE-START CHECK LIST

Make the following checks and perform the service required before each

2.1.1.Check tires and add or release air as needed to bring pressure in drive tires to: 12 psi (Turf Type Tires), 5 psi (All Terrain Type Tires) and 25 psi in rear caster tires. Pressure in front deck caster wheels should be 25 psi.

2.1.2.Check guards, deflectors and covers to make sure all are in place and securely tightened.

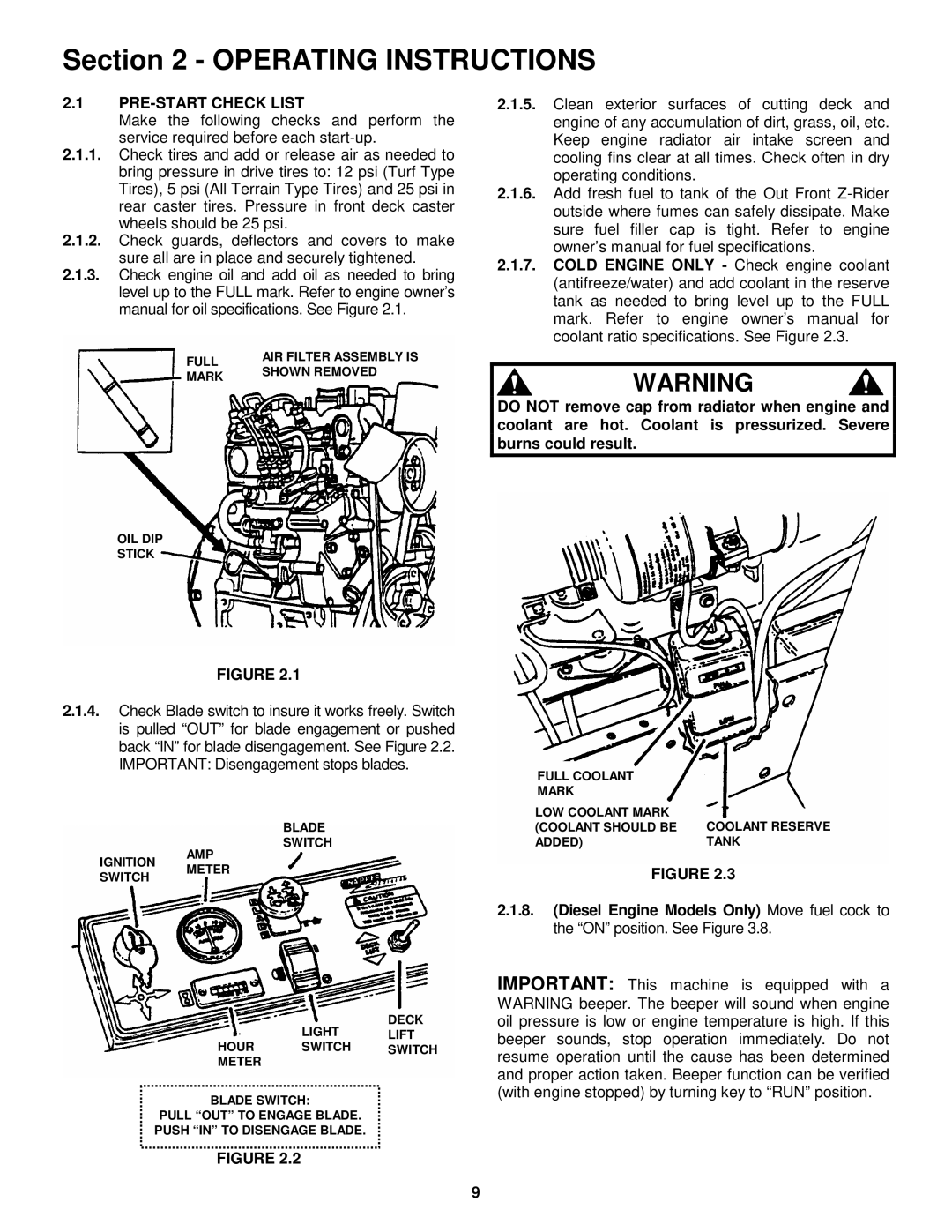

2.1.3.Check engine oil and add oil as needed to bring level up to the FULL mark. Refer to engine owner’s manual for oil specifications. See Figure 2.1.

FULL | AIR FILTER ASSEMBLY IS | |

SHOWN REMOVED | ||

MARK | ||

|

OIL DIP

STICK

FIGURE 2.1

2.1.4.Check Blade switch to insure it works freely. Switch is pulled “OUT” for blade engagement or pushed back “IN” for blade disengagement. See Figure 2.2. IMPORTANT: Disengagement stops blades.

2.1.5.Clean exterior surfaces of cutting deck and engine of any accumulation of dirt, grass, oil, etc. Keep engine radiator air intake screen and cooling fins clear at all times. Check often in dry operating conditions.

2.1.6.Add fresh fuel to tank of the Out Front

2.1.7.COLD ENGINE ONLY - Check engine coolant (antifreeze/water) and add coolant in the reserve tank as needed to bring level up to the FULL mark. Refer to engine owner’s manual for coolant ratio specifications. See Figure 2.3.

WARNING

DO NOT remove cap from radiator when engine and coolant are hot. Coolant is pressurized. Severe burns could result.

FULL COOLANT

MARK

IGNITION

BLADE

SWITCH

AMP

LOW COOLANT MARK | COOLANT RESERVE |

(COOLANT SHOULD BE | |

ADDED) | TANK |

SWITCH

METER

DECK

LIGHT LIFT

HOUR SWITCH SWITCH METER

BLADE SWITCH:

FIGURE 2.3

2.1.8.(Diesel Engine Models Only) Move fuel cock to the “ON” position. See Figure 3.8.

IMPORTANT: This machine is equipped with a WARNING beeper. The beeper will sound when engine oil pressure is low or engine temperature is high. If this beeper sounds, stop operation immediately. Do not resume operation until the cause has been determined and proper action taken. Beeper function can be verified (with engine stopped) by turning key to “RUN” position.

PULL “OUT” TO ENGAGE BLADE. PUSH “IN” TO DISENGAGE BLADE.

FIGURE 2.2

9