Section 3 – ADJUSTMENTS & REPAIR

3.1 SERVICE PARTS & ASSISTANCE

To retain the original quality of your Tiller, use only genuine SNAPPER replacement parts. Specify the model and serial number as found on the nameplate of your Tiller when contacting your SNAPPER Dealer for parts or service assistance.

3.2 STANDING THE TILLER ON END

WARNING

DO NOT attempt any adjustments, maintenance, service, or repairs with the engine running. Stop tines and engine. Remove spark plug wire and secure wire away from spark plug. DO NOT stand Tiller on end with the engine running! To avoid fuel leakage and potential FIRE HAZARD the fuel tank must be drained before standing tiller on end. Allow engine to cool for at least ten minutes before draining or refilling fuel. Wipe off any spilled fuel before starting engine. Take all necessary precautions to prevent fuel leakage BEFORE standing the Tiller on end. Any draining of fuel must be done outside with the engine cool and away from ignition sources. If the Tiller is stored on end for any length of time, check it frequently for signs of fuel and/or oil leakage. Use approved fuel container. DO NOT smoke near open fuel container. DO NOT drain or fill fuel tank indoors or when engine is running. DO NOT run engine indoors..

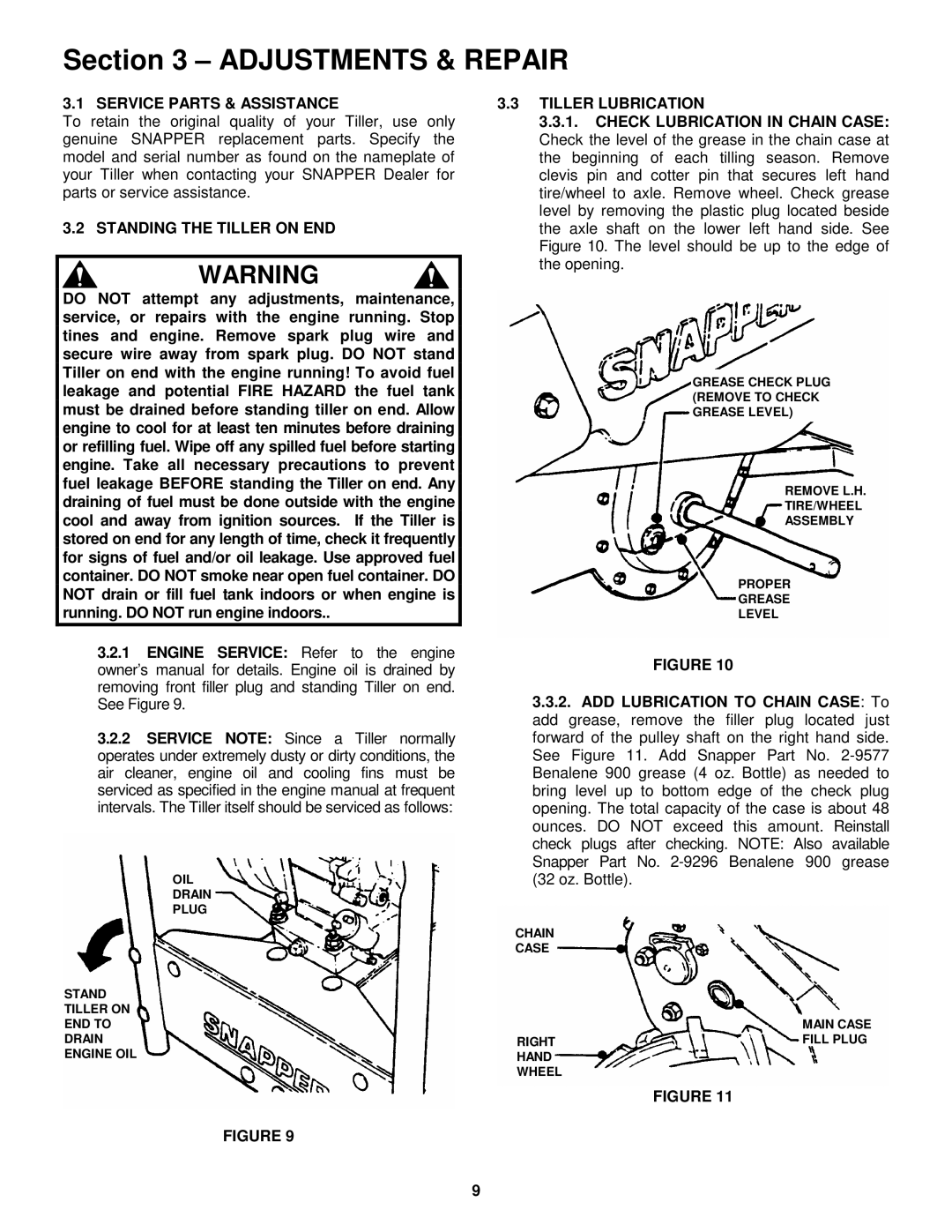

3.2.1ENGINE SERVICE: Refer to the engine owner’s manual for details. Engine oil is drained by removing front filler plug and standing Tiller on end. See Figure 9.

3.2.2SERVICE NOTE: Since a Tiller normally operates under extremely dusty or dirty conditions, the air cleaner, engine oil and cooling fins must be serviced as specified in the engine manual at frequent intervals. The Tiller itself should be serviced as follows:

OIL

DRAIN

PLUG

STAND

TILLER ON

END TO

DRAIN

ENGINE OIL

3.3TILLER LUBRICATION

3.3.1. CHECK LUBRICATION IN CHAIN CASE: Check the level of the grease in the chain case at the beginning of each tilling season. Remove clevis pin and cotter pin that secures left hand tire/wheel to axle. Remove wheel. Check grease level by removing the plastic plug located beside the axle shaft on the lower left hand side. See Figure 10. The level should be up to the edge of the opening.

GREASE CHECK PLUG (REMOVE TO CHECK GREASE LEVEL)

REMOVE L.H.

TIRE/WHEEL

ASSEMBLY

PROPER

GREASE

LEVEL

FIGURE 10

3.3.2.ADD LUBRICATION TO CHAIN CASE: To add grease, remove the filler plug located just forward of the pulley shaft on the right hand side. See Figure 11. Add Snapper Part No.

CHAIN

CASE

MAIN CASE

RIGHTFILL PLUG HAND

WHEEL

FIGURE 11

FIGURE 9

9