Section 4 - REPAIR & ADJUSTMENTS

4.5.BATTERY SERVICE

4.5.1. NEW BATTERY PREPARATION 1. Remove battery from carton.

2. Place battery in a well ventilated area on a level

3. Remove battery cell caps. Fill cells as required with electrolyte (supplied with battery) to proper level. Filling battery with electrolyte will bring the battery to 80% charged state.

4. With cell caps removed, connect battery charger to battery terminals; RED to positive (+) and BLACK to negative

IMPORTANT: Never place anything in battery other than specified electrolyte.

5.Slow charge the battery at 1 amp for 2 hours to bring the battery to full charge.

6.After charging, check level of electrolyte and add as needed to bring to proper fluid level.

7.Reinstall cell caps.

8.Install battery into power unit.

9.Connect positive (+) cable (red) first, from wiring harness to the positive terminal (+) on battery using bolt and nut provided in hardware bag. Connect negative

WARNING

DO NOT over fill battery with electrolyte. Shield the positive terminal with terminal cover located on battery harness. This prevents metal from touching the positive terminal, which could cause sparks. The electrolyte (acid) produces a highly explosive gas. Keep all sparks, flame and fire away from area when charging battery or when handling electrolyte or battery. Electrolyte (acid) is a highly corrosive liquid. Wear eye protection. Wash affected areas immediately after having eye or skin contact with electrolyte (acid). Battery acid is corrosive. Rinse empty acid containers with water and mutilate before discarding. If acid is spilled on battery, bench, or clothing, etc., Flush with clear water and neutralize with baking soda. Never attempt to charge battery while installed on the walk behind. Never use “BOOST” chargers on the battery.

4.5.4.BATTERY TESTING

4.5.2.BATTERY SERVICE 1. Remove battery.

2. Place battery in a well ventilated area on a level surface.

3. Using distilled water, refill cells as required to cover cell plates.

4. With cell caps removed, connect battery charger to battery terminals. Red to positive (+) terminal and black to negative

5. Slow charge battery at 1 amp for 10 hours.

6. If battery will not accept charge or is partially charged after 10 hours of charging at 1 amp, replace with new battery.

4.5.3.BATTERY STORAGE

If Walk Behind is to be stored out of season on its rear bumper, it is recommended the battery be removed, charged and stored.

1.Remove battery.

2.Perform battery service.

3.Bring battery to full charge, if required.

4.Store battery in an area away from the Walk Behind on a wood surface. DO NOT STORE BATTERY ON A CONCRETE SURFACE.

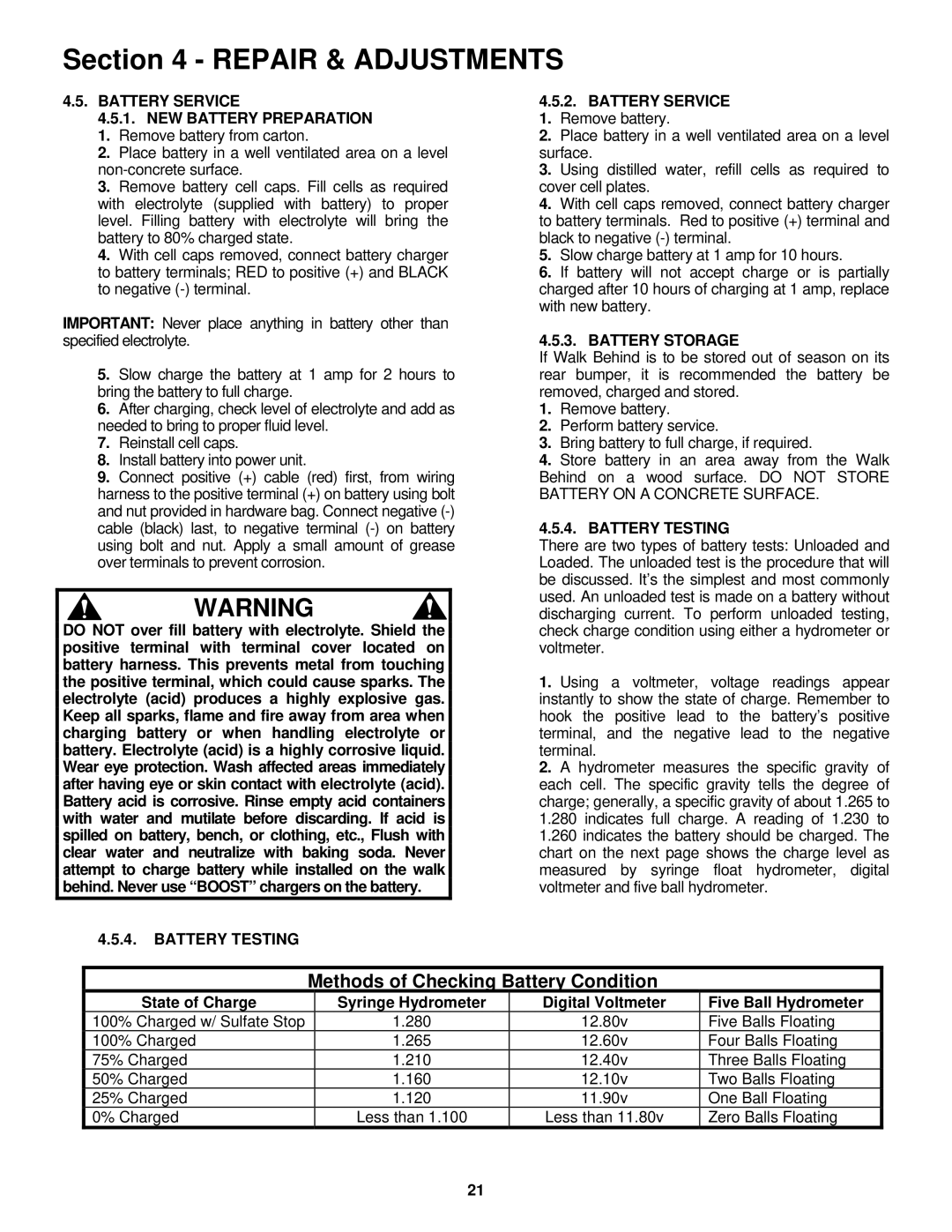

4.5.4. BATTERY TESTING

There are two types of battery tests: Unloaded and Loaded. The unloaded test is the procedure that will be discussed. It’s the simplest and most commonly used. An unloaded test is made on a battery without discharging current. To perform unloaded testing, check charge condition using either a hydrometer or voltmeter.

1.Using a voltmeter, voltage readings appear instantly to show the state of charge. Remember to hook the positive lead to the battery’s positive terminal, and the negative lead to the negative terminal.

2.A hydrometer measures the specific gravity of each cell. The specific gravity tells the degree of charge; generally, a specific gravity of about 1.265 to 1.280 indicates full charge. A reading of 1.230 to 1.260 indicates the battery should be charged. The chart on the next page shows the charge level as measured by syringe float hydrometer, digital voltmeter and five ball hydrometer.

Methods of Checking Battery Condition

| State of Charge | Syringe Hydrometer | Digital Voltmeter | Five Ball Hydrometer |

100% | Charged w/ Sulfate Stop | 1.280 | 12.80v | Five Balls Floating |

100% | Charged | 1.265 | 12.60v | Four Balls Floating |

75% Charged | 1.210 | 12.40v | Three Balls Floating | |

50% Charged | 1.160 | 12.10v | Two Balls Floating | |

25% Charged | 1.120 | 11.90v | One Ball Floating | |

0% Charged | Less than 1.100 | Less than 11.80v | Zero Balls Floating | |

21