SECTION 6 - BATTERY SERVICE & TESTING

6.5 NEW BATTERY PREPARATION

1.Remove battery from carton.

2.Place battery in a well ventilated area on a level non- concrete surface.

3.Remove battery cell caps. Fill cells as required with electrolyte (purchased separately) to proper level. Filling battery with electrolyte will bring the battery to 80% charged state.

4.With cell caps removed, connect battery charger to battery terminals; RED to positive (+) and BLACK to negative

IMPORTANT: DO NOT place anything in battery other than specified electrolyte.

WARNING

DO NOT OVERFILL!

WARNING

Shield the positive terminal with terminal cover located on battery harness. This prevents metal from touching the positive terminal, which could cause sparks. Cables must be connected to battery terminals in the proper position. RED (Positive) cable must go to the ( + ) terminal. BLACK (Negative) cable must go to the ( - ) terminal.

WARNING

DO NOT attempt to service or charge the battery while it is installed in the machine. DO NOT use “BOOST” chargers on the battery.

5.Slow charge the battery at 1 amp for 2 hours to bring the battery to full charge.

6.After charging, check level of electrolyte and add as needed to bring to proper level.

7.Reinstall cell caps.

8.Install battery into power unit.

9.Connect positive (+) cable (red) first, from wiring harness to the positive terminal (+) on battery using bolt and nut provided in hardware bag. Connect negative

10.Install battery retainer and positive terminal cover.

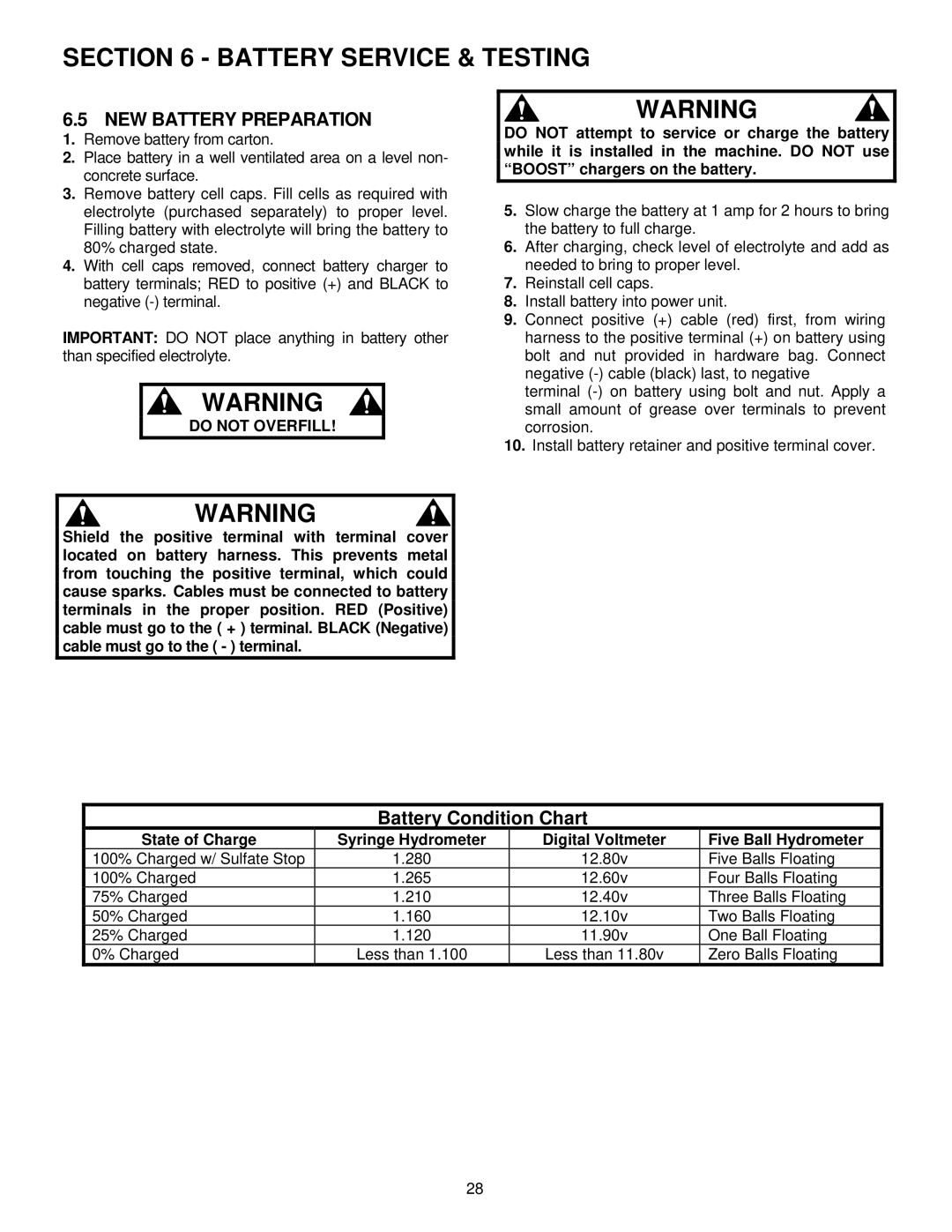

Battery Condition Chart

| State of Charge | Syringe Hydrometer | Digital Voltmeter | Five Ball Hydrometer |

100% | Charged w/ Sulfate Stop | 1.280 | 12.80v | Five Balls Floating |

100% | Charged | 1.265 | 12.60v | Four Balls Floating |

75% Charged | 1.210 | 12.40v | Three Balls Floating | |

50% Charged | 1.160 | 12.10v | Two Balls Floating | |

25% Charged | 1.120 | 11.90v | One Ball Floating | |

0% Charged | Less than 1.100 | Less than 11.80v | Zero Balls Floating | |

28