SECTION 4

MECHANICAL ADJUSTMENTS

PRECAUTION

1. Wipe the following components with an absorbent cotton cloth moistened with alcohol before adjustment :

PB head | Pinch roller |

Idler | Rubber belt |

Capstan |

|

2. | Demagnetize the PB head using a head demagnetizer. |

3. | Be careful not to use a magnetized screwdriver. |

4. | After the adjustment is completed, lock the adjustment parts |

| using screws. |

SECTION 5

ELECTRICAL ADJUSTMENTS

See the adjustment location from on page 28 for the adjust- ment.

TAPE SECTION |

| 0 dB = 0.775 V |

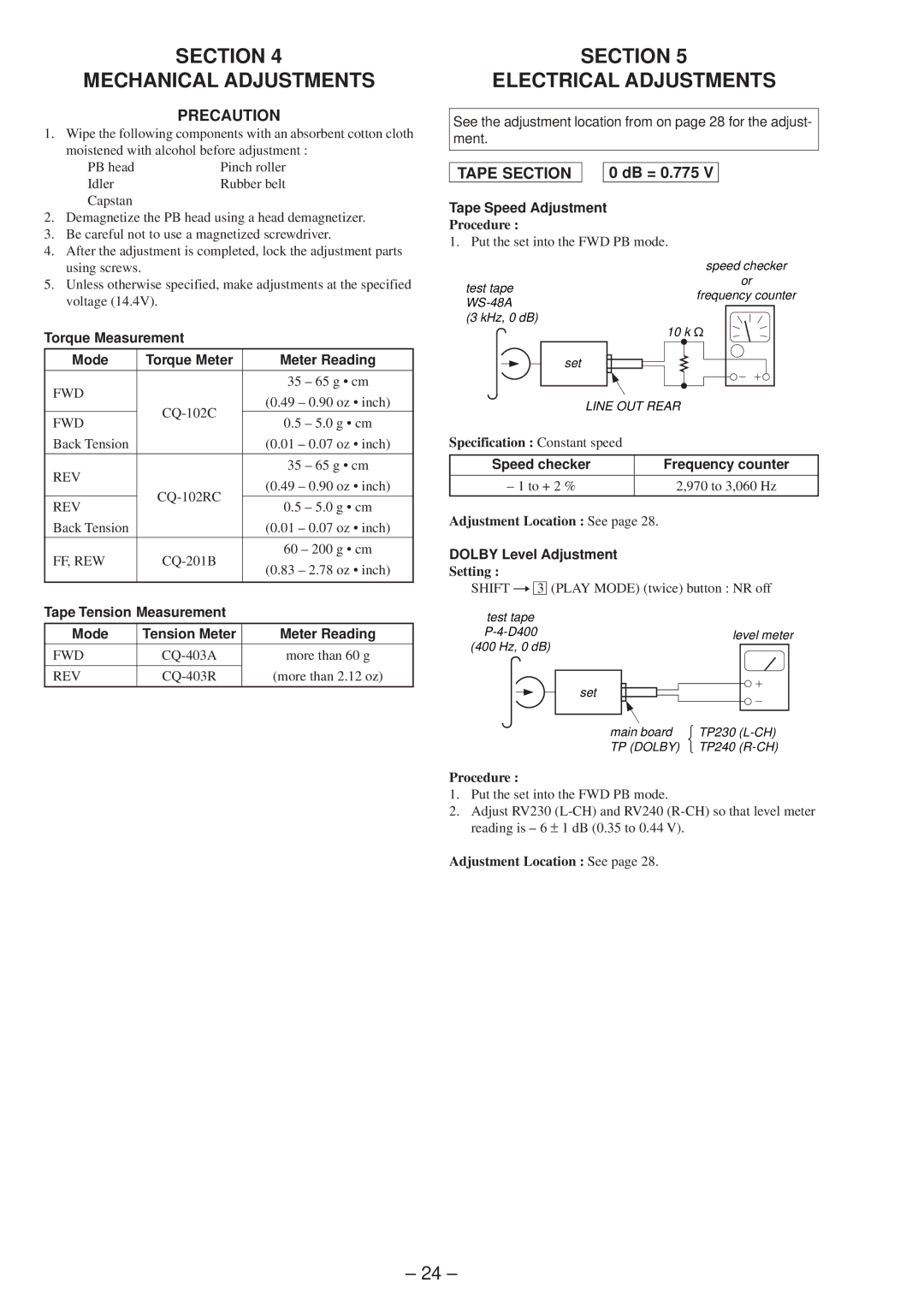

Tape Speed Adjustment

Procedure :

1. Put the set into the FWD PB mode.

speed checker

5. Unless otherwise specified, make adjustments at the specified |

test tape

or

voltage (14.4V). |

frequency counter

Torque Measurement

Mode | Torque Meter | Meter Reading | |

|

|

| |

FWD |

| 35 – 65 g • cm | |

| (0.49 – 0.90 oz • inch) | ||

| |||

|

| ||

FWD | 0.5 – 5.0 g • cm | ||

| |||

Back Tension |

| (0.01 – 0.07 oz • inch) | |

|

|

| |

REV |

| 35 – 65 g • cm | |

| (0.49 – 0.90 oz • inch) | ||

| |||

|

| ||

REV | 0.5 – 5.0 g • cm | ||

| |||

Back Tension |

| (0.01 – 0.07 oz • inch) | |

|

|

| |

FF, REW | 60 – 200 g • cm | ||

(0.83 – 2.78 oz • inch) | |||

|

| ||

|

|

| |

Tape Tension Measurement |

| ||

|

|

| |

Mode | Tension Meter | Meter Reading | |

FWD | more than 60 g | ||

|

|

| |

REV | (more than 2.12 oz) | ||

|

|

| |

(3 kHz, 0 dB)

| 10 k ½ |

set |

|

LINE OUT REAR | |

Specification : Constant speed |

|

Speed checker | Frequency counter |

– 1 to + 2 % | 2,970 to 3,060 Hz |

Adjustment Location : See page 28.

DOLBY Level Adjustment

Setting :

SHIFT n 3 (PLAY MODE) (twice) button : NR off

test tape

set

main board | TP230 | |

TP (DOLBY) | TP240 |

Procedure :

1.Put the set into the FWD PB mode.

2.Adjust RV230

Adjustment Location : See page 28.

– 24 –