Care & Maintenance

3

!

Always disconnect machine from power before performing maintenance or serious personal injury may result.

6 |

5 |

4 |

7 |

For optimum performance from your chuck, follow the maintenance schedule below, and never hammer on the chuck, jaws, or a workpiece clamped in the chuck. Never subject the chuck to abrasives, flame, or water.

Daily:

•Check/correct loose mounting bolts.

•Keep the chuck clean and oiled.

•Use a vacuum, rag, or brush to clean the chuck after use. Never use air pressure to clean chips away from a chuck.

•Avoid leaving the chuck clamped on a workpiece, unload the chuck jaws daily.

•Make sure the chuck key is removed from the chuck when not using the key.

If the chuck ever becomes stiff to operate, it may have been contaminated with metal chips or abrasives from neglect or poor service practices. The chuck must be dissembled, cleaned, and re- lubricated.

To disassemble the chuck for a full cleaning and lubrication service:

1.UNPLUG THE MACHINE FROM POWER!

2.Mark the chuck and the mounting plate where they mate to ensure that when reassembled both halves line up. Next, unbolt the chuck and separate both halves.

3.Insert and rotate the chuck key counterclockwise until the

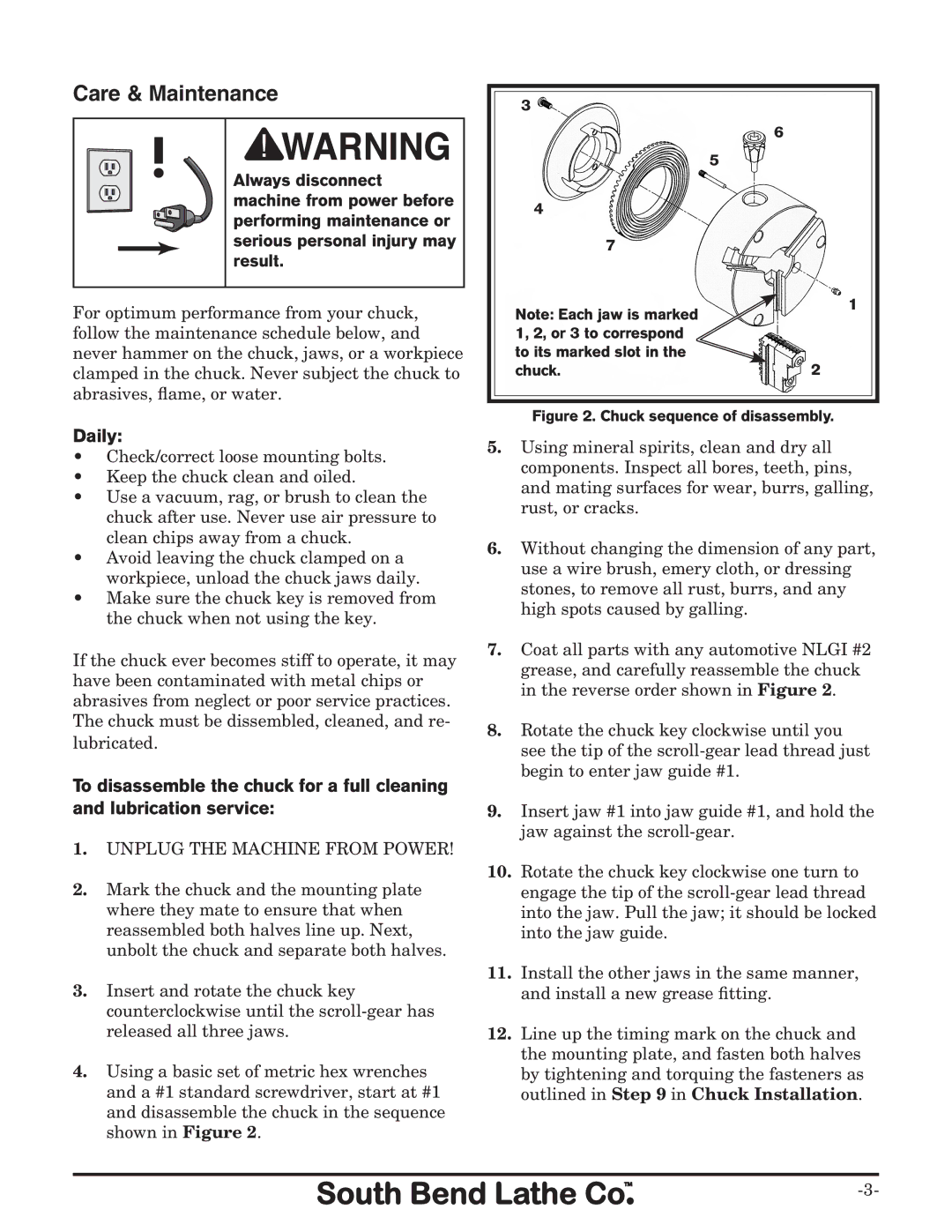

4.Using a basic set of metric hex wrenches and a #1 standard screwdriver, start at #1 and disassemble the chuck in the sequence shown in Figure 2.

Note: Each jaw is marked | 1 |

|

1, 2, or 3 to correspond to its marked slot in the

chuck.2

Figure 2. Chuck sequence of disassembly.

5.Using mineral spirits, clean and dry all components. Inspect all bores, teeth, pins, and mating surfaces for wear, burrs, galling, rust, or cracks.

6.Without changing the dimension of any part, use a wire brush, emery cloth, or dressing stones, to remove all rust, burrs, and any high spots caused by galling.

7.Coat all parts with any automotive NLGI #2 grease, and carefully reassemble the chuck in the reverse order shown in Figure 2.

8.Rotate the chuck key clockwise until you see the tip of the

9.Insert jaw #1 into jaw guide #1, and hold the jaw against the

10.Rotate the chuck key clockwise one turn to engage the tip of the

11.Install the other jaws in the same manner, and install a new grease fitting.

12.Line up the timing mark on the chuck and the mounting plate, and fasten both halves by tightening and torquing the fasteners as outlined in Step 9 in Chuck Installation.