PBV200 LE specifications

The Poulan PBV200 LE is a powerful and versatile leaf blower designed for homeowners and professionals alike, making outdoor maintenance tasks more efficient and hassle-free. With its robust engine and thoughtful design, this blower stands out in a crowded market, appealing to those looking for both performance and ease of use.One of the key features of the PBV200 LE is its 200cc engine, delivering an impressive airflow speed of up to 200 mph. This robust engine not only provides strong suction and blowing performance, but it also ensures a quicker clean-up of leaves, grass clippings, and other debris, making yard work a breeze. The engine is designed with a focus on fuel efficiency, allowing users to work for extended periods without frequent refueling.

In terms of ergonomics, the PBV200 LE showcases a lightweight design, making it easy to maneuver around the yard. Weighing in at just 11.5 pounds, it minimizes user fatigue during extended use. The blower also features an adjustable handle and padded straps, allowing for a customized fit that ensures comfort and stability, even during long durations of operation.

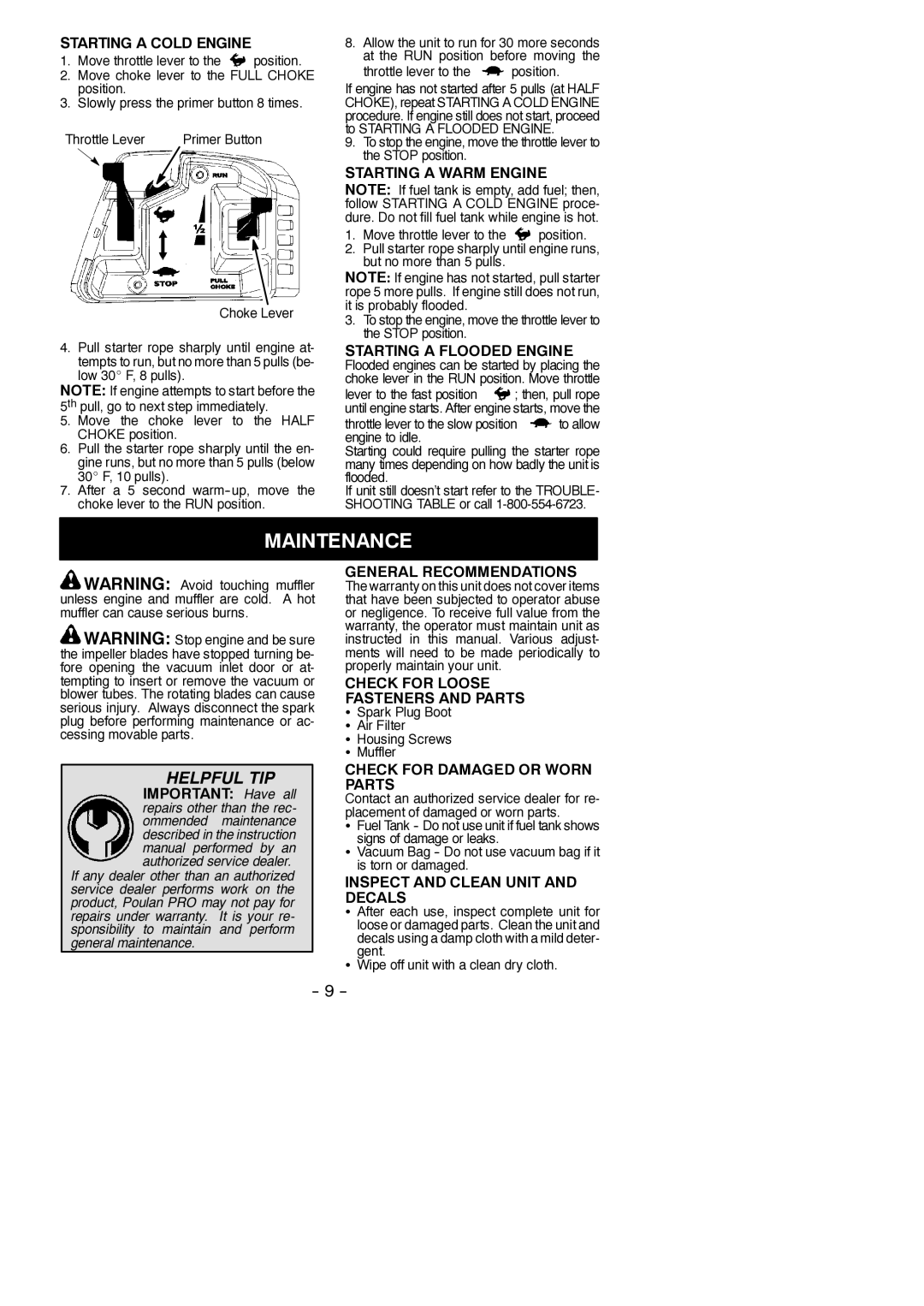

The technology incorporated into the PBV200 LE enhances its usability. An easy-start system enables quick ignition, while the low-vibration function reduces user fatigue and increases control, allowing for precise maneuvering. Additionally, the blower features a vacuum and mulching function, which allows for dual-use applications. This versatility not only saves time but also promotes efficient yard waste management by shredding leaves into mulch.

Not to be overlooked is the PBV200 LE's environmentally friendly design. It meets or exceeds EPA emissions standards, providing peace of mind to users who are conscious of their environmental footprint. This commitment to sustainability without sacrificing performance makes it an ideal choice for eco-conscious homeowners.

With its combination of power, comfort, and eco-friendly design, the Poulan PBV200 LE is a reliable leaf blower that meets the demands of outdoor cleaning tasks. Whether tackling seasonal leaf fall or maintaining garden spaces, this model delivers exceptional performance and convenience that enhances any landscaping strategy.