600 specifications

SPX Cooling Technologies, a leader in thermal management solutions, has designed the SPX Cooling Technologies 600, a cutting-edge cooling system that addresses the growing demands of industrial and commercial applications. This advanced cooling tower is engineered to enhance efficiency, reduce environmental impact, and deliver reliable performance across various settings.One of the standout features of the SPX Cooling Technologies 600 is its compact and modular design, which allows for easy installation and maintenance. Its scalable configurations make it versatile, enabling it to adapt to a wide range of cooling requirements without compromising performance. The unit is built with high-quality materials that ensure durability and resistance to corrosion, making it suitable for long-term operation in harsh environments.

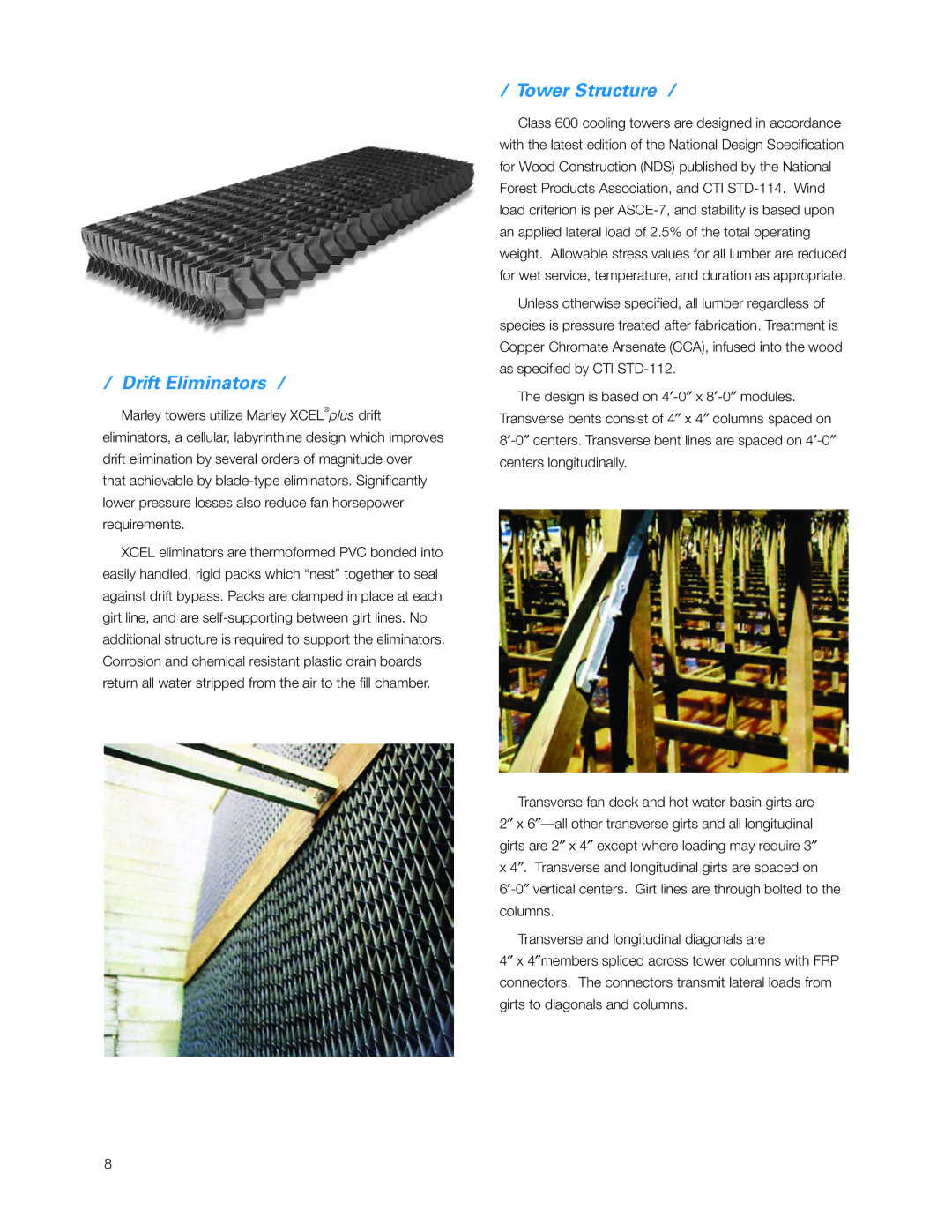

The cooling system incorporates advanced technology such as the latest in evaporative cooling principles. It utilizes a crossflow design that maximizes airflow and enhances heat exchange, resulting in improved energy efficiency. The innovative fan design, coupled with high-efficiency motors, reduces electrical consumption while maintaining optimal cooling capacities.

Another key characteristic of the SPX Cooling Technologies 600 is its exceptional noise reduction capabilities. The unit is designed to operate quietly, which is particularly beneficial in urban environments or in applications where noise pollution is a concern. The integration of sound-dampening features further enhances its appeal for sensitive installations.

The cooling tower is also equipped with smart controls that allow for real-time monitoring and adjustments. This intelligent system can optimize operations based on environmental conditions and load requirements, ensuring that the cooling process is as efficient as possible. Additionally, the SPX Cooling Technologies 600 supports integration with existing building management systems, providing seamless operation and data analytics capabilities.

For improved water management, the SPX Cooling Technologies 600 features advanced water treatment options that minimize scaling and microbiological growth. This design not only extends the lifespan of the unit but also contributes to reduced maintenance costs.

In summary, the SPX Cooling Technologies 600 is a state-of-the-art cooling solution that combines innovative design, energy efficiency, and enhanced performance. With its modular construction, advanced technologies, and smart controls, it sets a new standard for industrial and commercial cooling applications, ensuring reliable operation while meeting stringent environmental regulations.