TROUBLESHOOTING

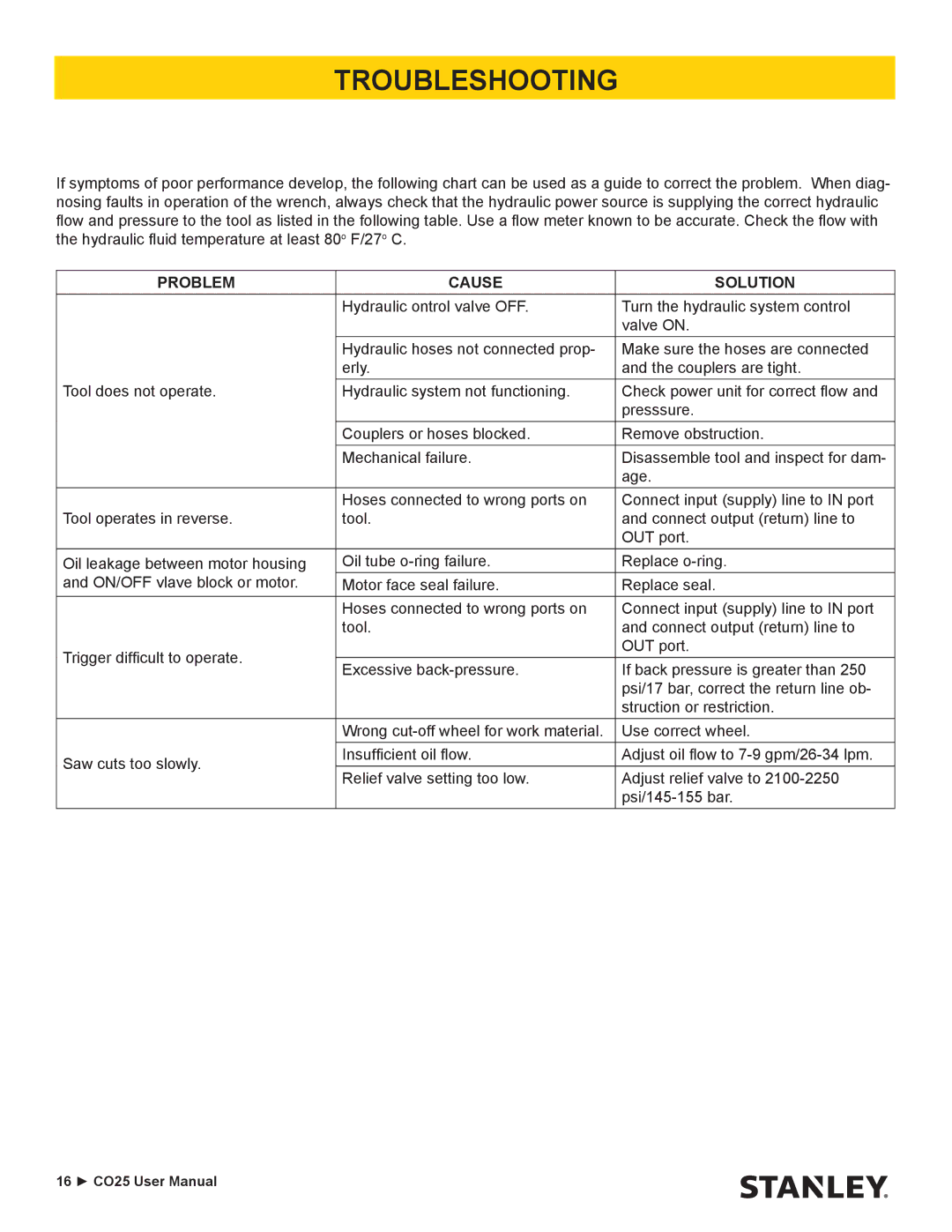

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem. When diag- nosing faults in operation of the wrench, always check that the hydraulic power source is supplying the correct hydraulic flow and pressure to the tool as listed in the following table. Use a flow meter known to be accurate. Check the flow with the hydraulic fluid temperature at least 80o F/27o C.

PROBLEM | CAUSE | SOLUTION | |

| Hydraulic ontrol valve OFF. | Turn the hydraulic system control | |

|

| valve ON. | |

| Hydraulic hoses not connected prop- | Make sure the hoses are connected | |

| erly. | and the couplers are tight. | |

Tool does not operate. | Hydraulic system not functioning. | Check power unit for correct flow and | |

|

| presssure. | |

| Couplers or hoses blocked. | Remove obstruction. | |

| Mechanical failure. | Disassemble tool and inspect for dam- | |

|

| age. | |

| Hoses connected to wrong ports on | Connect input (supply) line to IN port | |

Tool operates in reverse. | tool. | and connect output (return) line to | |

|

| OUT port. | |

Oil leakage between motor housing | Oil tube | Replace | |

and ON/OFF vlave block or motor. | Motor face seal failure. | Replace seal. | |

| Hoses connected to wrong ports on | Connect input (supply) line to IN port | |

| tool. | and connect output (return) line to | |

Trigger difficult to operate. |

| OUT port. | |

Excessive | If back pressure is greater than 250 | ||

| |||

|

| psi/17 bar, correct the return line ob- | |

|

| struction or restriction. | |

| Wrong | Use correct wheel. | |

Saw cuts too slowly. | Insufficient oil flow. | Adjust oil flow to | |

Relief valve setting too low. | Adjust relief valve to | ||

| |||

|

|

16 ► CO25 User Manual