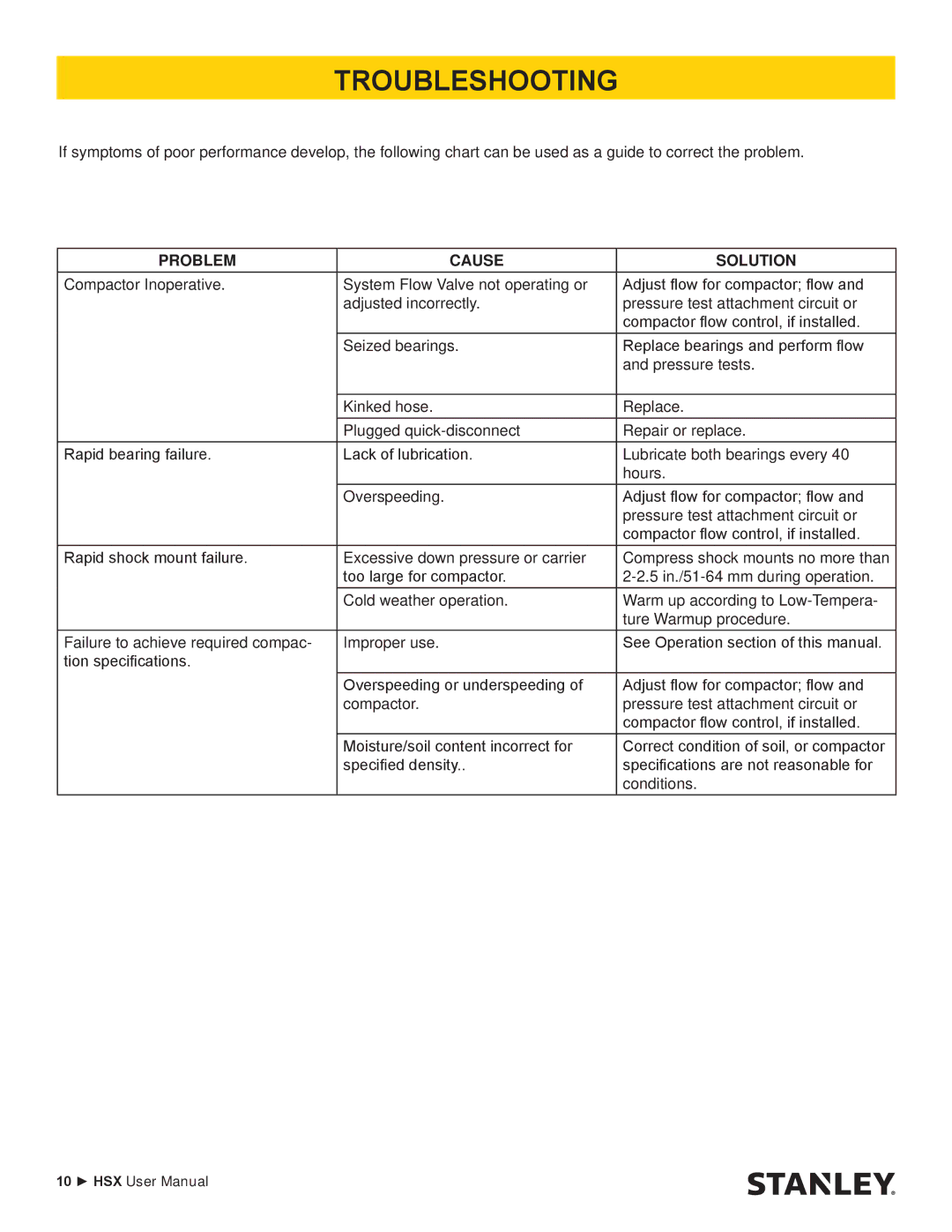

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

PROBLEM | CAUSE | SOLUTION |

Compactor Inoperative. | System Flow Valve not operating or | Adjust flow for compactor; flow and |

| adjusted incorrectly. | pressure test attachment circuit or |

|

| compactor flow control, if installed. |

| Seized bearings. | Replace bearings and perform flow |

|

| and pressure tests. |

|

|

|

| Kinked hose. | Replace. |

| Plugged | Repair or replace. |

Rapid bearing failure. | Lack of lubrication. | Lubricate both bearings every 40 |

|

| hours. |

| Overspeeding. | Adjust flow for compactor; flow and |

|

| pressure test attachment circuit or |

|

| compactor flow control, if installed. |

Rapid shock mount failure. | Excessive down pressure or carrier | Compress shock mounts no more than |

| too large for compactor. | |

| Cold weather operation. | Warm up according to |

|

| ture Warmup procedure. |

Failure to achieve required compac- | Improper use. | See Operation section of this manual. |

tion specifications. |

|

|

| Overspeeding or underspeeding of | Adjust flow for compactor; flow and |

| compactor. | pressure test attachment circuit or |

|

| compactor flow control, if installed. |

| Moisture/soil content incorrect for | Correct condition of soil, or compactor |

| specified density.. | specifications are not reasonable for |

|

| conditions. |

10 ► HSX User Manual