FADER CLEANING

The SK FOUR faders may need lubrication from time to time. This will extend the fader life and eliminate any potential damage due to extended heavy usage. Follow the instruction below the lubricate your faders:

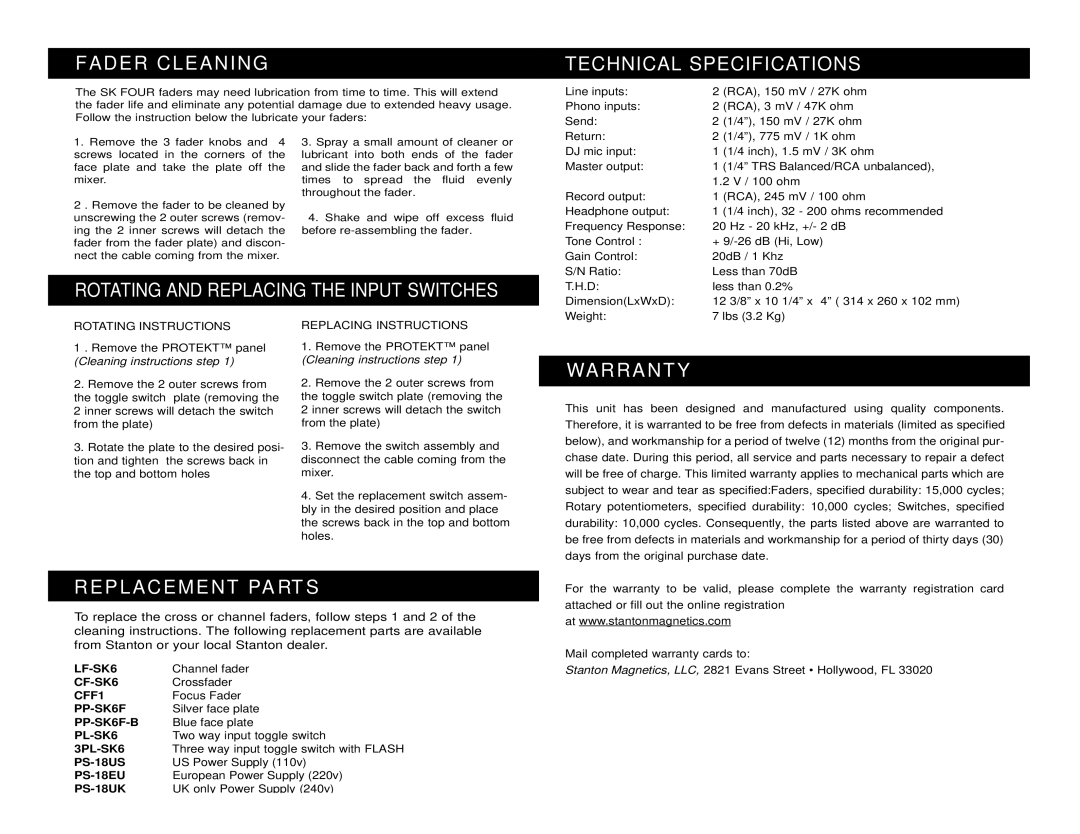

TECHNICAL SPECIFICATIONS

Line inputs: | 2 | (RCA), 150 mV / 27K ohm | |

Phono inputs: | 2 (RCA), 3 mV / 47K ohm | ||

Send: | 2 (1/4”), | 150 mV / 27K ohm | |

Return: | 2 | (1/4”), | 775 mV / 1K ohm |

1.Remove the 3 fader knobs and 4 screws located in the corners of the face plate and take the plate off the mixer.

2 . Remove the fader to be cleaned by unscrewing the 2 outer screws (remov- ing the 2 inner screws will detach the fader from the fader plate) and discon- nect the cable coming from the mixer.

3.Spray a small amount of cleaner or lubricant into both ends of the fader and slide the fader back and forth a few times to spread the fluid evenly throughout the fader.

4.Shake and wipe off excess fluid before

DJ mic input: | 1 | (1/4 inch), 1.5 mV / 3K ohm |

Master output: | 1 | (1/4” TRS Balanced/RCA unbalanced), |

| 1.2 V / 100 ohm | |

Record output: | 1 | (RCA), 245 mV / 100 ohm |

Headphone output: | 1 | (1/4 inch), 32 - 200 ohms recommended |

Frequency Response: | 20 Hz - 20 kHz, +/- 2 dB | |

Tone Control : | + | |

Gain Control: | 20dB / 1 Khz | |

S/N Ratio: | Less than 70dB | |

ROTATING AND REPLACING THE INPUT SWITCHES

T.H.D: | less than 0.2% |

Dimension(LxWxD): | 12 3/8” x 10 1/4” x 4” ( 314 x 260 x 102 mm) |

Weight: | 7 lbs (3.2 Kg) |

ROTATING INSTRUCTIONS

1 . Remove the PROTEKT™ panel (Cleaning instructions step 1)

2.Remove the 2 outer screws from the toggle switch plate (removing the

2inner screws will detach the switch from the plate)

3.Rotate the plate to the desired posi- tion and tighten the screws back in the top and bottom holes

REPLACING INSTRUCTIONS

1.Remove the PROTEKT™ panel (Cleaning instructions step 1)

2.Remove the 2 outer screws from the toggle switch plate (removing the

2inner screws will detach the switch from the plate)

3.Remove the switch assembly and disconnect the cable coming from the mixer.

4.Set the replacement switch assem- bly in the desired position and place the screws back in the top and bottom holes.

WA R R A N T Y

This unit has been designed and manufactured using quality components. Therefore, it is warranted to be free from defects in materials (limited as specified below), and workmanship for a period of twelve (12) months from the original pur- chase date. During this period, all service and parts necessary to repair a defect will be free of charge. This limited warranty applies to mechanical parts which are subject to wear and tear as specified:Faders, specified durability: 15,000 cycles; Rotary potentiometers, specified durability: 10,000 cycles; Switches, specified durability: 10,000 cycles. Consequently, the parts listed above are warranted to be free from defects in materials and workmanship for a period of thirty days (30) days from the original purchase date.

R E P L A C E M E N T PA RT S

To replace the cross or channel faders, follow steps 1 and 2 of the cleaning instructions. The following replacement parts are available from Stanton or your local Stanton dealer.

Channel fader | |

Crossfader | |

CFF1 | Focus Fader |

Silver face plate | |

Blue face plate | |

Two way input toggle switch | |

Three way input toggle switch with FLASH | |

US Power Supply (110v) | |

European Power Supply (220v) | |

| UK only Power Supply (240v) |

For the warranty to be valid, please complete the warranty registration card attached or fill out the online registration

at www.stantonmagnetics.com

Mail completed warranty cards to:

Stanton Magnetics, LLC, 2821 Evans Street • Hollywood, FL 33020