TONE ARM AND CARTRIDGE SETTING

The major cause of problems in sound and skipping on the vinyl is the lack of proper set up of the needle and turntable adjustments. The needle is designed to operate at a specific angle to the vinyl. The T.92 USB has several adjustments to correctly position the needle to the vinyl.

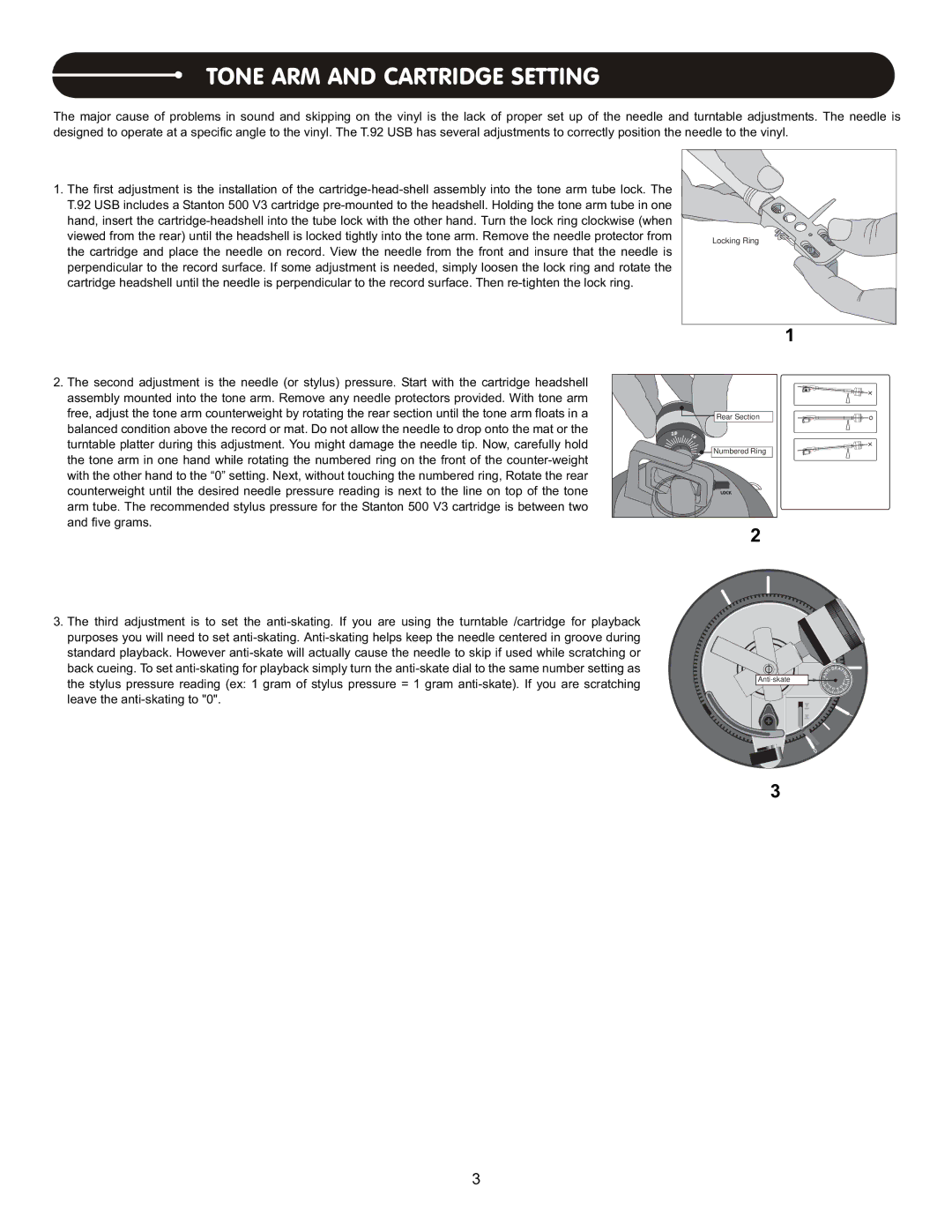

1. The first adjustment is the installation of the |

|

| |

T.92 USB includes a Stanton 500 V3 cartridge |

|

| |

hand, insert the |

|

| |

viewed from the rear) until the headshell is locked tightly into the tone arm. Remove the needle protector from |

| Locking Ring | |

the cartridge and place the needle on record. View the needle from the front and insure that the needle is |

|

| |

perpendicular to the record surface. If some adjustment is needed, simply loosen the lock ring and rotate the |

|

| |

cartridge headshell until the needle is perpendicular to the record surface. Then |

|

|

|

|

|

| 1 |

2. The second adjustment is the needle (or stylus) pressure. Start with the cartridge headshell |

|

|

|

assembly mounted into the tone arm. Remove any needle protectors provided. With tone arm |

|

|

|

free, adjust the tone arm counterweight by rotating the rear section until the tone arm floats in a |

|

| Rear Section |

balanced condition above the record or mat. Do not allow the needle to drop onto the mat or the | 2.0 | 1. |

|

turntable platter during this adjustment. You might damage the needle tip. Now, carefully hold |

| 0 |

|

|

| Numbered Ring | |

the tone arm in one hand while rotating the numbered ring on the front of the |

| 0 | |

|

|

| |

with the other hand to the “0” setting. Next, without touching the numbered ring, Rotate the rear |

|

|

|

counterweight until the desired needle pressure reading is next to the line on top of the tone |

|

|

|

arm tube. The recommended stylus pressure for the Stanton 500 V3 cartridge is between two |

|

|

|

and five grams. |

|

| 2 |

|

|

| |

3.The third adjustment is to set the

3

3