2. Lubrication

Lubrication is very important to maintain optimum performance and to prevent trouble.

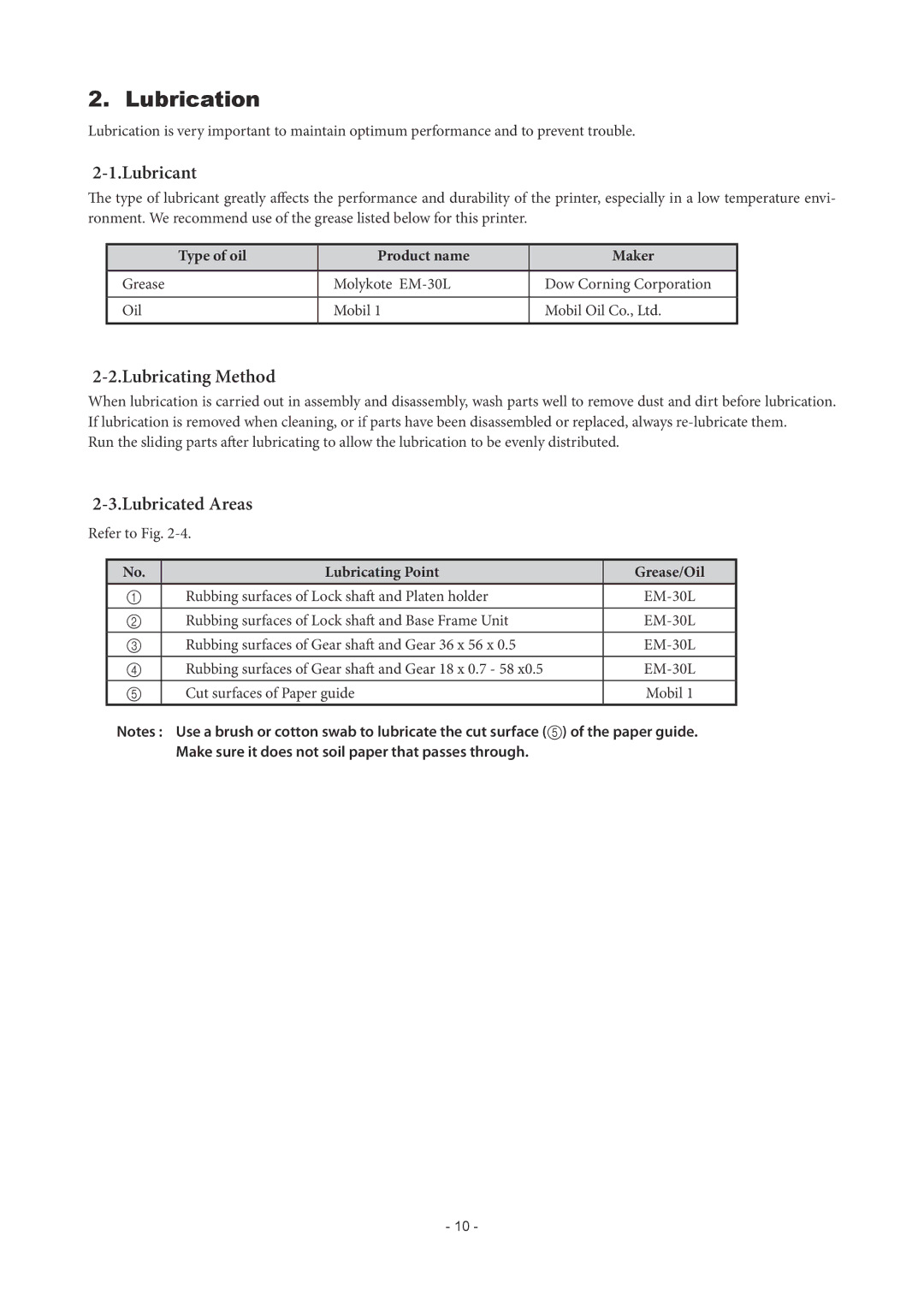

2-1.Lubricant

The type of lubricant greatly affects the performance and durability of the printer, especially in a low temperature envi ronment. We recommend use of the grease listed below for this printer.

Type of oil | Product name | Maker |

Grease | Molykote | Dow Corning Corporation |

|

|

|

Oil | Mobil 1 | Mobil Oil Co., Ltd. |

2-2.Lubricating Method

When lubrication is carried out in assembly and disassembly, wash parts well to remove dust and dirt before lubrication. If lubrication is removed when cleaning, or if parts have been disassembled or replaced, always

Run the sliding parts after lubricating to allow the lubrication to be evenly distributed.

2-3.Lubricated Areas

Refer to Fig.

No. | Lubricating Point | Grease/Oil |

1 | Rubbing surfaces of Lock shaft and Platen holder | |

2 | Rubbing surfaces of Lock shaft and Base Frame Unit | |

3 | Rubbing surfaces of Gear shaft and Gear 36 x 56 x 0.5 | |

4 | Rubbing surfaces of Gear shaft and Gear 18 x 0.7 - 58 x0.5 | |

5 | Cut surfaces of Paper guide | Mobil 1 |

Notes : Use a brush or cotton swab to lubricate the cut surface (5) of the paper guide.

Make sure it does not soil paper that passes through.

- 10 -