Ignition Module System

Before calling your service agent, the following checklist should be examined to eliminate obvious problems from those requiring replacement or servicing.

•Check that “main manual gas shutoff valve” is fully open and that gas service has not been interrupted.

•Check that after following the appliance OPERATING INSTRUCTIONS, the “Top Knob” of the appliance gas valve is in “ON” position.

•Check electrical supply to the appliance for possible blown (or tripped) fusing or power interruption. Also check the 3 amp fuse on the front of the digital thermostat (Fig. 2).

•Is the water temperature in tank below the thermostat dial setting on the appliance thermostat (calling for heat)?

•It is possible that the high limit (E.C.O.) has functioned to shut off the appliance. See High Limit page 7 - High Limit Switch for reset procedure. Contact your service agent if limit continues to function to shut off appliance.

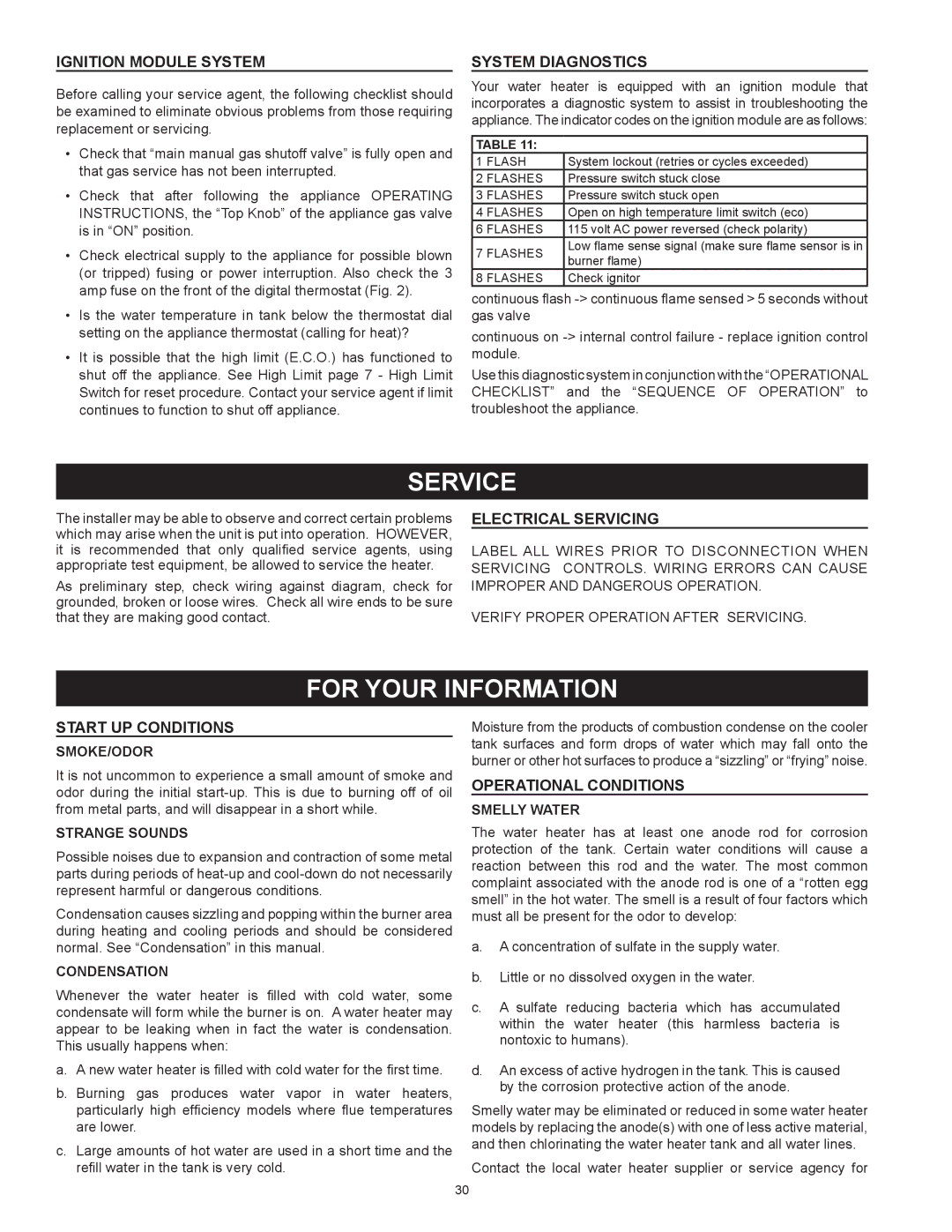

System Diagnostics

Your water heater is equipped with an ignition module that incorporates a diagnostic system to assist in troubleshooting the appliance. The indicator codes on the ignition module are as follows:

TABLE 11:

1 FLASH | System lockout (retries or cycles exceeded) | |

2 FLASHES | Pressure switch stuck close | |

3 FLASHES | Pressure switch stuck open | |

4 FLASHES | Open on high temperature limit switch (eco) | |

6 FLASHES | 115 volt AC power reversed (check polarity) | |

7 FLASHES | Low flame sense signal (make sure flame sensor is in | |

burner flame) | ||

| ||

8 FLASHES | Check ignitor |

continuous flash

continuous on

Use this diagnostic system in conjunction with the “OPERATIONAL CHECKLIST” and the “SEQUENCE OF OPERATION” to troubleshoot the appliance.

SERVICE

The installer may be able to observe and correct certain problems which may arise when the unit is put into operation. HOWEVER, it is recommended that only qualified service agents, using appropriate test equipment, be allowed to service the heater.

As preliminary step, check wiring against diagram, check for grounded, broken or loose wires. Check all wire ends to be sure that they are making good contact.

Electrical Servicing

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

for your information

Start Up Conditions

SMOKE/ODOR

It is not uncommon to experience a small amount of smoke and odor during the initial

STRANGE SOUNDS

Possible noises due to expansion and contraction of some metal parts during periods of

Condensation causes sizzling and popping within the burner area during heating and cooling periods and should be considered normal. See “Condensation” in this manual.

CONDENSATION

Whenever the water heater is filled with cold water, some condensate will form while the burner is on. A water heater may appear to be leaking when in fact the water is condensation. This usually happens when:

a.A new water heater is filled with cold water for the first time.

b.Burning gas produces water vapor in water heaters, particularly high efficiency models where flue temperatures are lower.

c.Large amounts of hot water are used in a short time and the refill water in the tank is very cold.

Moisture from the products of combustion condense on the cooler tank surfaces and form drops of water which may fall onto the burner or other hot surfaces to produce a “sizzling” or “frying” noise.

Operational Conditions

SMELLY WATER

The water heater has at least one anode rod for corrosion protection of the tank. Certain water conditions will cause a reaction between this rod and the water. The most common complaint associated with the anode rod is one of a “rotten egg smell” in the hot water. The smell is a result of four factors which must all be present for the odor to develop:

a.A concentration of sulfate in the supply water.

b.Little or no dissolved oxygen in the water.

c.A sulfate reducing bacteria which has accumulated within the water heater (this harmless bacteria is nontoxic to humans).

d.An excess of active hydrogen in the tank. This is caused by the corrosion protective action of the anode.

Smelly water may be eliminated or reduced in some water heater models by replacing the anode(s) with one of less active material, and then chlorinating the water heater tank and all water lines.

Contact the local water heater supplier or service agency for

30