ENGLISH

5.8AFTER USE

1.Check for loose or damaged parts. If required, change damaged parts.

2.Tighten loose screws and nuts.

3.Brush all the snow from the machine.

4.Move all the controls backwards and forwards a few times.

5.Put the choke in position ![]()

6.Disconnect the starting cable from the spark plug.

Do not cover the machine while the engine and silencer are still warm.

6MAINTENANCE

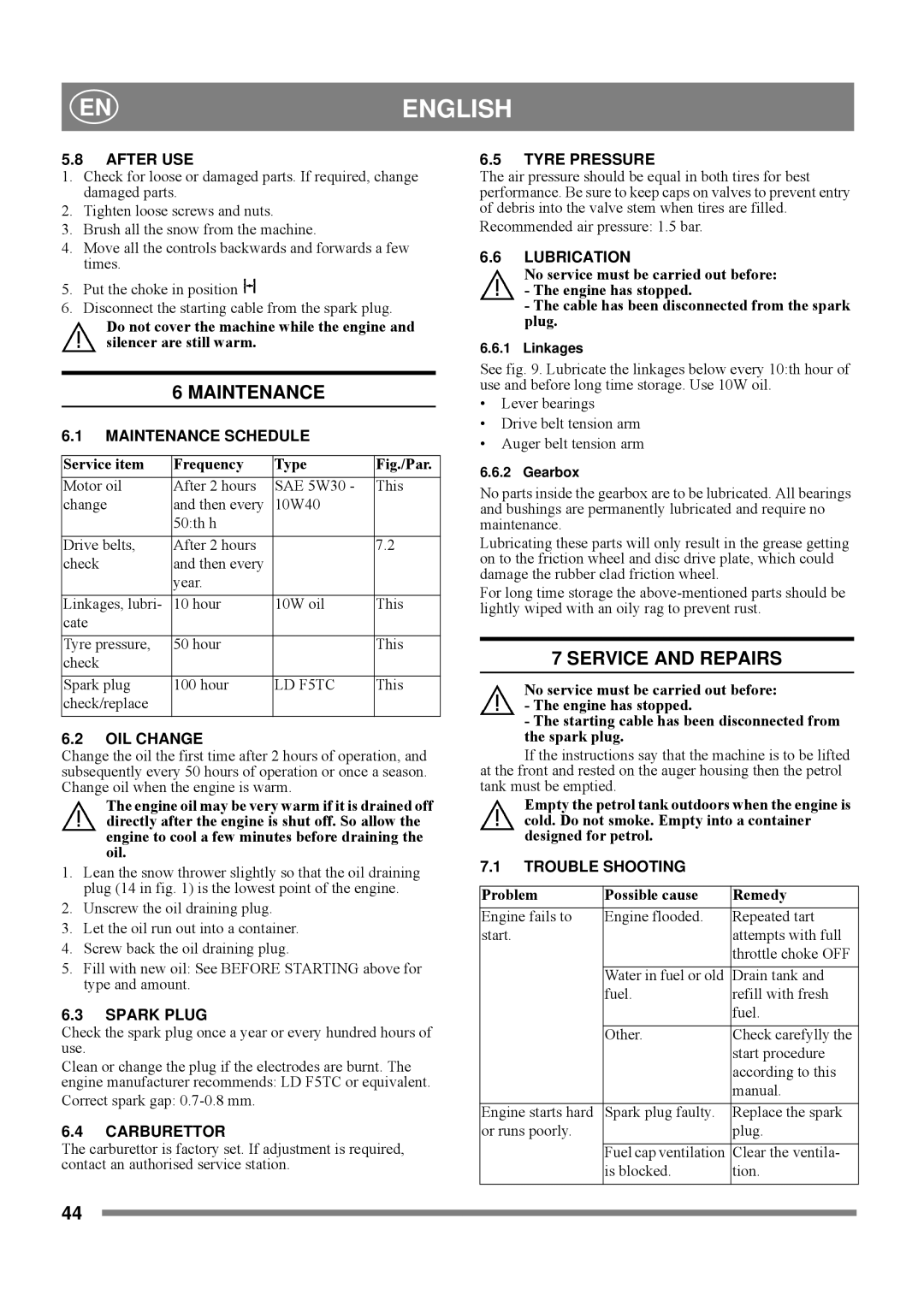

6.1MAINTENANCE SCHEDULE

Service item | Frequency | Type | Fig./Par. |

Motor oil | After 2 hours | SAE 5W30 - | This |

change | and then every | 10W40 |

|

| 50:th h |

|

|

|

|

|

|

Drive belts, | After 2 hours |

| 7.2 |

check | and then every |

|

|

| year. |

|

|

|

|

|

|

Linkages, lubri- | 10 hour | 10W oil | This |

cate |

|

|

|

|

|

|

|

Tyre pressure, | 50 hour |

| This |

check |

|

|

|

|

|

|

|

Spark plug | 100 hour | LD F5TC | This |

check/replace |

|

|

|

|

|

|

|

6.2OIL CHANGE

Change the oil the first time after 2 hours of operation, and subsequently every 50 hours of operation or once a season. Change oil when the engine is warm.

The engine oil may be very warm if it is drained off directly after the engine is shut off. So allow the engine to cool a few minutes before draining the oil.

1.Lean the snow thrower slightly so that the oil draining plug (14 in fig. 1) is the lowest point of the engine.

2.Unscrew the oil draining plug.

3.Let the oil run out into a container.

4.Screw back the oil draining plug.

5.Fill with new oil: See BEFORE STARTING above for type and amount.

6.3SPARK PLUG

Check the spark plug once a year or every hundred hours of use.

Clean or change the plug if the electrodes are burnt. The engine manufacturer recommends: LD F5TC or equivalent.

Correct spark gap:

6.4CARBURETTOR

The carburettor is factory set. If adjustment is required, contact an authorised service station.

44

6.5TYRE PRESSURE

The air pressure should be equal in both tires for best performance. Be sure to keep caps on valves to prevent entry of debris into the valve stem when tires are filled.

Recommended air pressure: 1.5 bar.

6.6LUBRICATION

No service must be carried out before:

-The engine has stopped.

-The cable has been disconnected from the spark plug.

6.6.1 Linkages

See fig. 9. Lubricate the linkages below every 10:th hour of use and before long time storage. Use 10W oil.

•Lever bearings

•Drive belt tension arm

•Auger belt tension arm

6.6.2 Gearbox

No parts inside the gearbox are to be lubricated. All bearings and bushings are permanently lubricated and require no maintenance.

Lubricating these parts will only result in the grease getting on to the friction wheel and disc drive plate, which could damage the rubber clad friction wheel.

For long time storage the

7 SERVICE AND REPAIRS

No service must be carried out before:

-The engine has stopped.

-The starting cable has been disconnected from the spark plug.

If the instructions say that the machine is to be lifted at the front and rested on the auger housing then the petrol tank must be emptied.

Empty the petrol tank outdoors when the engine is cold. Do not smoke. Empty into a container designed for petrol.

7.1TROUBLE SHOOTING

Problem | Possible cause | Remedy |

Engine fails to | Engine flooded. | Repeated tart |

start. |

| attempts with full |

|

| throttle choke OFF |

|

|

|

| Water in fuel or old | Drain tank and |

| fuel. | refill with fresh |

|

| fuel. |

|

|

|

| Other. | Check carefylly the |

|

| start procedure |

|

| according to this |

|

| manual. |

|

|

|

Engine starts hard | Spark plug faulty. | Replace the spark |

or runs poorly. |

| plug. |

|

|

|

| Fuel cap ventilation | Clear the ventila- |

| is blocked. | tion. |

|

|

|