SERVICING INSTRUCTIONS

REPLACING PARTS

8.MAIN INJECTOR

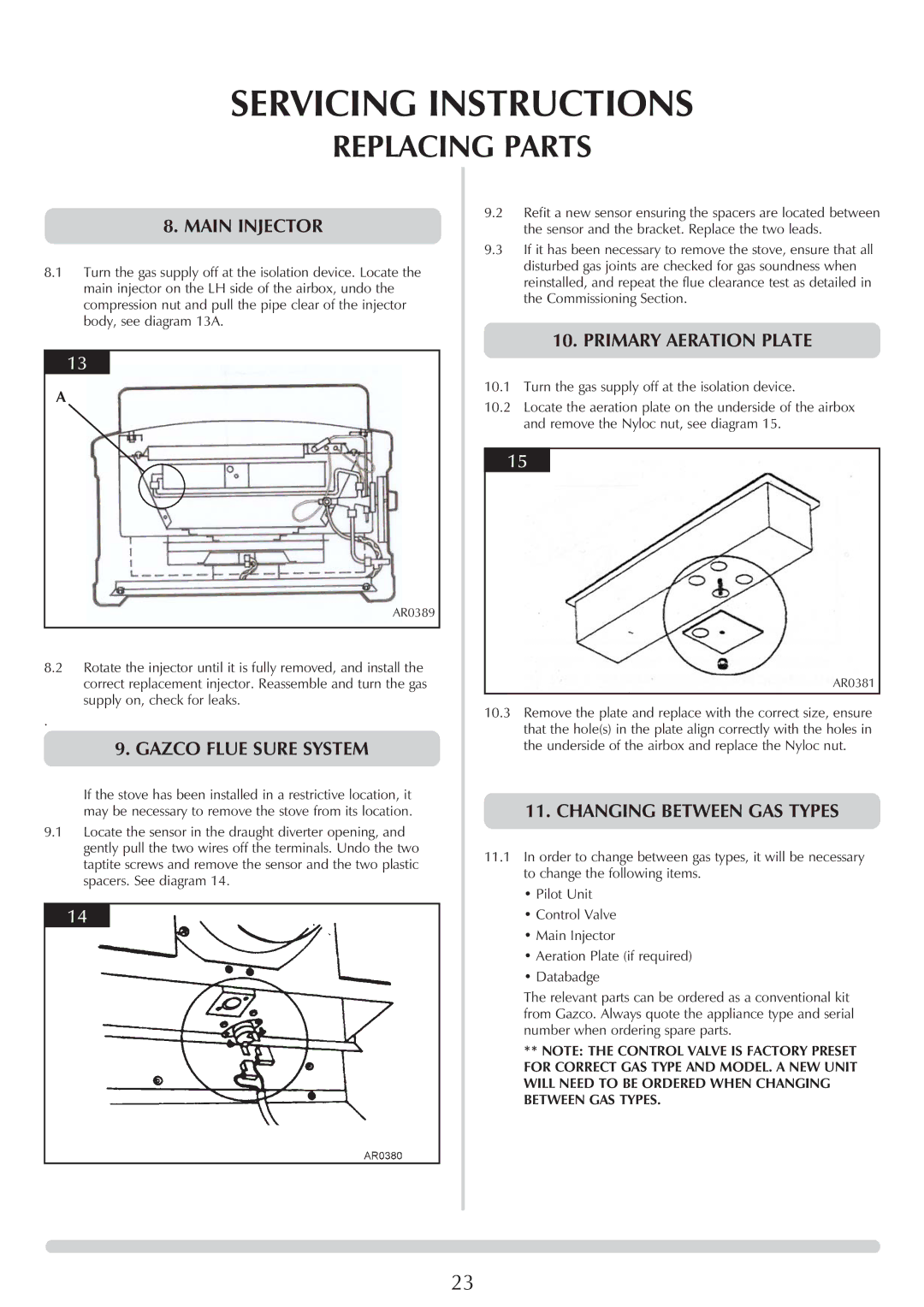

8.1Turn the gas supply off at the isolation device. Locate the main injector on the LH side of the airbox, undo the compression nut and pull the pipe clear of the injector body, see diagram 13A.

13

A

AR0389

8.2Rotate the injector until it is fully removed, and install the correct replacement injector. Reassemble and turn the gas supply on, check for leaks.

.

9. GAZCO FLUE SURE SYSTEM

If the stove has been installed in a restrictive location, it may be necessary to remove the stove from its location.

9.1Locate the sensor in the draught diverter opening, and gently pull the two wires off the terminals. Undo the two taptite screws and remove the sensor and the two plastic spacers. See diagram 14.

14

9.2Refit a new sensor ensuring the spacers are located between the sensor and the bracket. Replace the two leads.

9.3If it has been necessary to remove the stove, ensure that all disturbed gas joints are checked for gas soundness when reinstalled, and repeat the flue clearance test as detailed in the Commissioning Section.

10.PRIMARY AERATION PLATE

10.1Turn the gas supply off at the isolation device.

10.2Locate the aeration plate on the underside of the airbox and remove the Nyloc nut, see diagram 15.

15

AR0381

10.3Remove the plate and replace with the correct size, ensure that the hole(s) in the plate align correctly with the holes in the underside of the airbox and replace the Nyloc nut.

11.CHANGING BETWEEN GAS TYPES

11.1In order to change between gas types, it will be necessary to change the following items.

•Pilot Unit

•Control Valve

•Main Injector

•Aeration Plate (if required)

•Databadge

The relevant parts can be ordered as a conventional kit from Gazco. Always quote the appliance type and serial number when ordering spare parts.

**NOTE: THE CONTROL VALVE IS FACTORY PRESET FOR CORRECT GAS TYPE AND MODEL. A NEW UNIT WILL NEED TO BE ORDERED WHEN CHANGING BETWEEN GAS TYPES.

23