ASSEMBLY INSTRUCTIONS/OPERATIONS

General Notes Regarding the Installation of Flails

1)Because of variance in material thickness and manufacturing tolerances, the specified number of spacer washers may not always fit within the narrow and wide sections. If this occurs, grinding a spacer washer to reduce its thickness is an option.

FIGURE 20

![]() CAUTION

CAUTION

Exercise caution when grinding a spacer washer to reduce its thickness. Wear safety eye wear and other, appropriate safety apparel to minimize the potential for personal injury.

2)Flails require sufficient free play to allow them to properly impact the work surface material. If the flails fit too tight on the drum, inconsistent material removal and accelerated flail wear will result. The formation of rust between the flail and spacer washer surfaces will affect proper free play. Excessive free play can also accelerate the wear of flails and rods. As a general rule, flails should be free to rotate by hand after being installed on the drum. If this is not possible, the flails should be disassembled and additional free play provided by reducing the thickness of a spacer washer.

3)All flails are

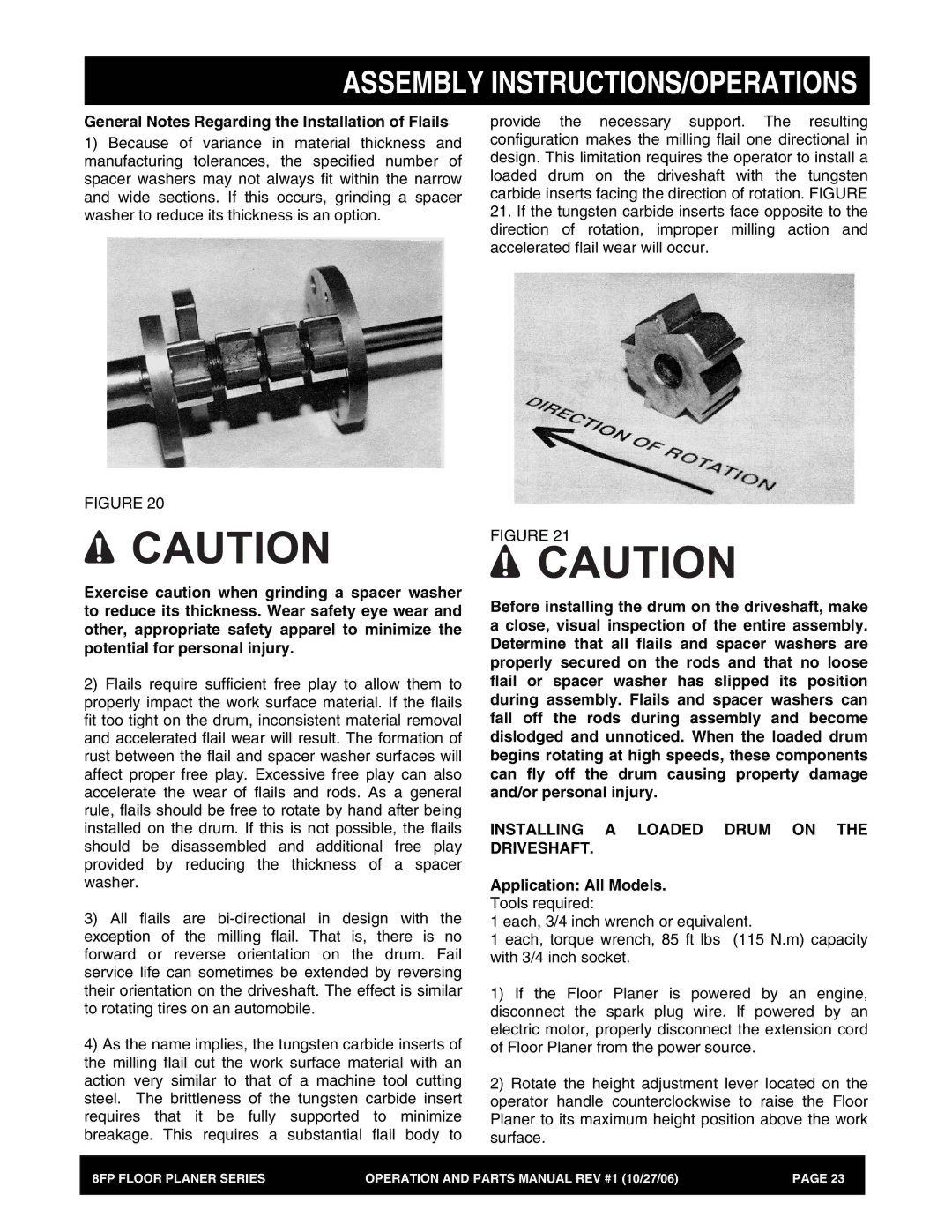

4)As the name implies, the tungsten carbide inserts of the milling flail cut the work surface material with an action very similar to that of a machine tool cutting steel. The brittleness of the tungsten carbide insert requires that it be fully supported to minimize breakage. This requires a substantial flail body to

provide the necessary support. The resulting configuration makes the milling flail one directional in design. This limitation requires the operator to install a loaded drum on the driveshaft with the tungsten carbide inserts facing the direction of rotation. FIGURE

21.If the tungsten carbide inserts face opposite to the direction of rotation, improper milling action and accelerated flail wear will occur.

FIGURE 21

![]() CAUTION

CAUTION

Before installing the drum on the driveshaft, make a close, visual inspection of the entire assembly. Determine that all flails and spacer washers are properly secured on the rods and that no loose flail or spacer washer has slipped its position during assembly. Flails and spacer washers can fall off the rods during assembly and become dislodged and unnoticed. When the loaded drum begins rotating at high speeds, these components can fly off the drum causing property damage and/or personal injury.

INSTALLING A LOADED DRUM ON THE DRIVESHAFT.

Application: All Models.

Tools required:

1 each, 3/4 inch wrench or equivalent.

1 each, torque wrench, 85 ft lbs (115 N.m) capacity with 3/4 inch socket.

1)If the Floor Planer is powered by an engine, disconnect the spark plug wire. If powered by an electric motor, properly disconnect the extension cord of Floor Planer from the power source.

2)Rotate the height adjustment lever located on the operator handle counterclockwise to raise the Floor Planer to its maximum height position above the work surface.

8FP FLOOR PLANER SERIES | OPERATION AND PARTS MANUAL REV #1 (10/27/06) | PAGE 23 |

|

|

|