ASSEMBLY INSTRUCTIONS/OPERATIONS

adifferent process and can not be achieved with the Floor Planer.

4) The The Floor Planer features a "down feed" type design for the flail drum. The flail drum rotates forward and towards the front of the machine before the flails impact the work surface and remove material. The rotational direction of the drum produces a "self- propelled" effect that assists the operator when pushing the machine forward. Conversely, when the operator pulls the machine back towards himself, he must exert an additional force to overcome the "self- propelling" force.

ALWAYS MAINTAIN PROPER CONTROL OF THE FLOOR PLANER. IF AN OPERATOR LOOSES CONTROL OF THE MACHINE, A "RUNAWAY" FLOOR PLANER CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY. BECAUSE OF THE UNIQUE OPERATING CHARACTERISTICS OF THE FLOOR PLANER, THERE IS NO PROVISION FOR THE ELECTRIC MOTOR/ENGINE TO AUTOMATICALLY STOP IF THE OPERATOR FAILS TO MAINTAIN PROPER CONTROL.

![]() DANGER

DANGER

WHEN OPERATING THE FLOOR PLANER ON ABOVE GROUND LEVELS, EXERCISE EXTREME CAUTION TO PREVENT LOSS OF CONTROL THAT COULD ALLOW THE MACHINE AND/OR OPERATOR TO FALL DOWN TO LOWER LEVELS. SUCH AN OCCURRENCE CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

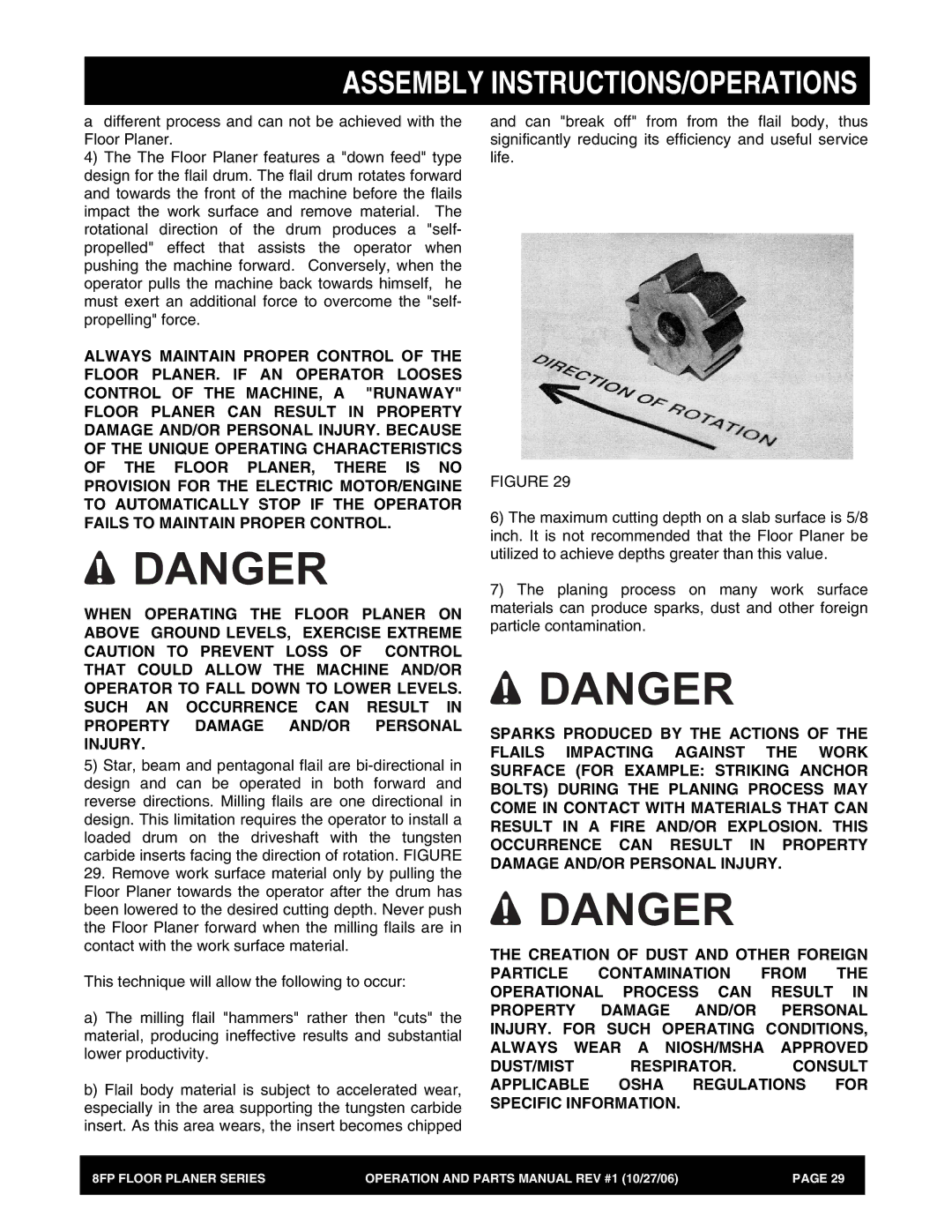

5)Star, beam and pentagonal flail are

This technique will allow the following to occur:

a)The milling flail "hammers" rather then "cuts" the material, producing ineffective results and substantial lower productivity.

b)Flail body material is subject to accelerated wear, especially in the area supporting the tungsten carbide insert. As this area wears, the insert becomes chipped

and can "break off" from from the flail body, thus significantly reducing its efficiency and useful service life.

FIGURE 29

6)The maximum cutting depth on a slab surface is 5/8 inch. It is not recommended that the Floor Planer be utilized to achieve depths greater than this value.

7)The planing process on many work surface materials can produce sparks, dust and other foreign particle contamination.

![]() DANGER

DANGER

SPARKS PRODUCED BY THE ACTIONS OF THE FLAILS IMPACTING AGAINST THE WORK SURFACE (FOR EXAMPLE: STRIKING ANCHOR BOLTS) DURING THE PLANING PROCESS MAY COME IN CONTACT WITH MATERIALS THAT CAN RESULT IN A FIRE AND/OR EXPLOSION. THIS OCCURRENCE CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

![]() DANGER

DANGER

THE CREATION OF DUST AND OTHER FOREIGN PARTICLE CONTAMINATION FROM THE OPERATIONAL PROCESS CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY. FOR SUCH OPERATING CONDITIONS, ALWAYS WEAR A NIOSH/MSHA APPROVED

DUST/MIST RESPIRATOR. CONSULT APPLICABLE OSHA REGULATIONS FOR SPECIFIC INFORMATION.

8FP FLOOR PLANER SERIES | OPERATION AND PARTS MANUAL REV #1 (10/27/06) | PAGE 29 |

|

|

|