PORTO-SCREED PSH — MAINTENANCE

MAINTENANCE

See the engine manual supplied with your machine for appropriate engine maintenance schedule and troubleshooting guide for problems.

CAUTION

ALWAYS allow the engine to cool before servicing. NEVER attempt any maintenance work on a hot! engine.

WARNING

BA

C

E

D

Whenever assembling, lubricating, cleaning or adjusting any part of the screed, make certain the engine is stopped with the spark plug wire disconnected and secured away from contact with the spark plug.

Lubrication

A.Engine: Lubricate the

B.Clutch: A few drops of lightweight oil occasionally squirted between the clutch mechanism cover and the floating cone will help keep the mechanism free of debris and is the only clutch maintenance required

C.Pillow Block Bearings: After every 40 hours of operation, remove the belt guard (Item B, Figure 18) and grease each bearing (Item D) with quality grade multi- purpose grease.

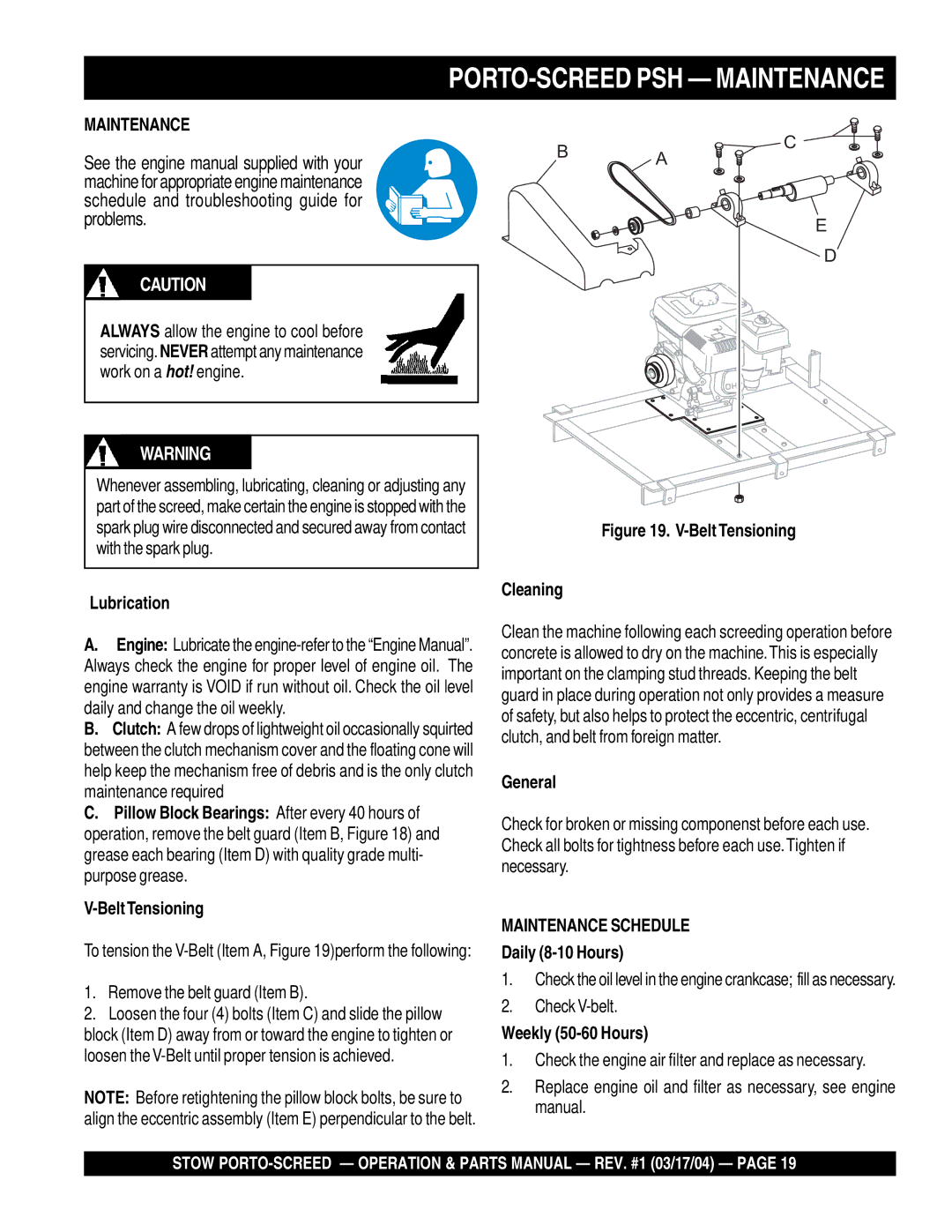

V-BeltTensioning

To tension the

1.Remove the belt guard (Item B).

2.Loosen the four (4) bolts (Item C) and slide the pillow block (Item D) away from or toward the engine to tighten or loosen the

NOTE: Before retightening the pillow block bolts, be sure to align the eccentric assembly (Item E) perpendicular to the belt.

Figure 19. V-Belt Tensioning

Cleaning

Clean the machine following each screeding operation before concrete is allowed to dry on the machine.This is especially important on the clamping stud threads. Keeping the belt guard in place during operation not only provides a measure of safety, but also helps to protect the eccentric, centrifugal clutch, and belt from foreign matter.

General

Check for broken or missing componenst before each use. Check all bolts for tightness before each use.Tighten if necessary.

MAINTENANCE SCHEDULE

Daily

1.Check the oil level in the engine crankcase; fill as necessary.

2.Check

Weekly (50-60 Hours)

1.Check the engine air filter and replace as necessary.

2.Replace engine oil and filter as necessary, see engine manual.

STOW