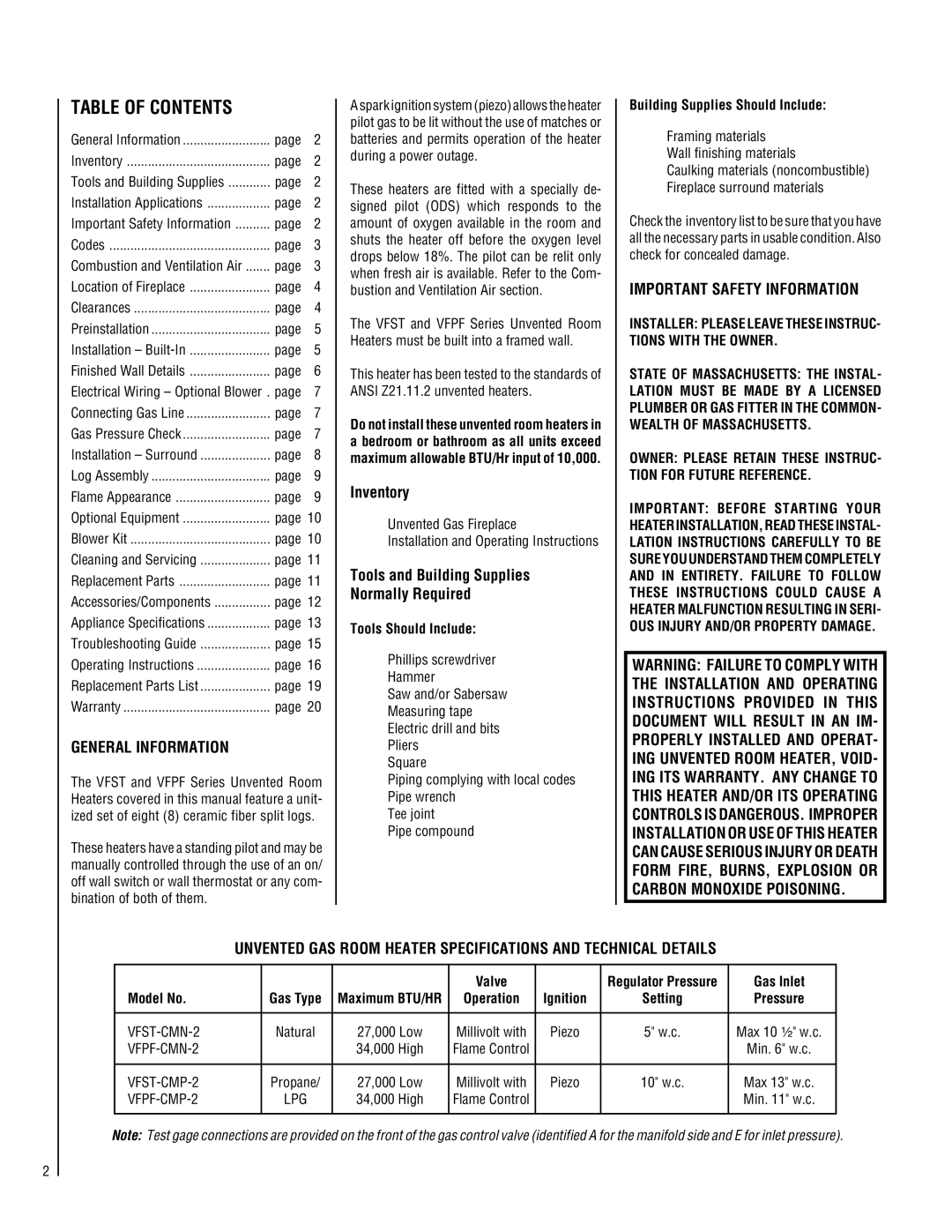

VFPF-CMP-2, VFPF-CMN-2, VFST-CMN-2, VFST-CMP-2 specifications

The Superior VFST-CMP-2, VFPF-CMN-2, VFPF-CMP-2, and VFST-CMN-2 represent a cutting-edge suite of products designed to meet the demands of modern applications in various industries, including telecommunications, data management, and industrial automation. Each of these models incorporates advanced features and technologies aimed at enhancing performance, reliability, and user experience.The VFST-CMP-2 is particularly focused on high-speed data processing. With an impressive throughput and low latency, it is engineered for tasks that require rapid data handling, making it suitable for applications in cloud computing and data centers. This model incorporates state-of-the-art error correction algorithms, ensuring data integrity during transmission and significantly reducing downtime.

In contrast, the VFPF-CMN-2 is tailored for network management and monitoring. It boasts a comprehensive interface that allows users to track network performance in real-time. The intuitive dashboard provides insights into traffic loads, bottlenecks, and overall system health. This model is equipped with cutting-edge analytics features that leverage machine learning to predict potential issues before they become critical, enhancing proactive maintenance capabilities.

The VFPF-CMP-2 combines features from both offerings, positioned as a hybrid solution that caters to versatile applications. It balances powerful data processing and efficient network management, making it an optimal choice for organizations looking to streamline operations across various platforms. With its modular architecture, users can easily scale their systems as demand increases without significant overhauls.

Finally, the VFST-CMN-2 excels in interoperability. Designed to integrate seamlessly with existing infrastructures, it supports a wide range of protocols and standards. This flexibility ensures that it can be deployed in diverse environments, minimizing compatibility issues. The device also emphasizes security, incorporating advanced encryption technologies to protect sensitive data during transmission.

In summary, the Superior VFST-CMP-2, VFPF-CMN-2, VFPF-CMP-2, and VFST-CMN-2 are exemplary models that bring together innovative features and technologies. Their unique characteristics make them well-suited for various applications, providing essential tools for enhanced data processing, network management, and operational efficiency. Organizations investing in these products are poised to benefit from improved performance and adaptability in an ever-evolving technological landscape.