Figure 3b: Wiring Diagram, 4W-B and 4WT-B

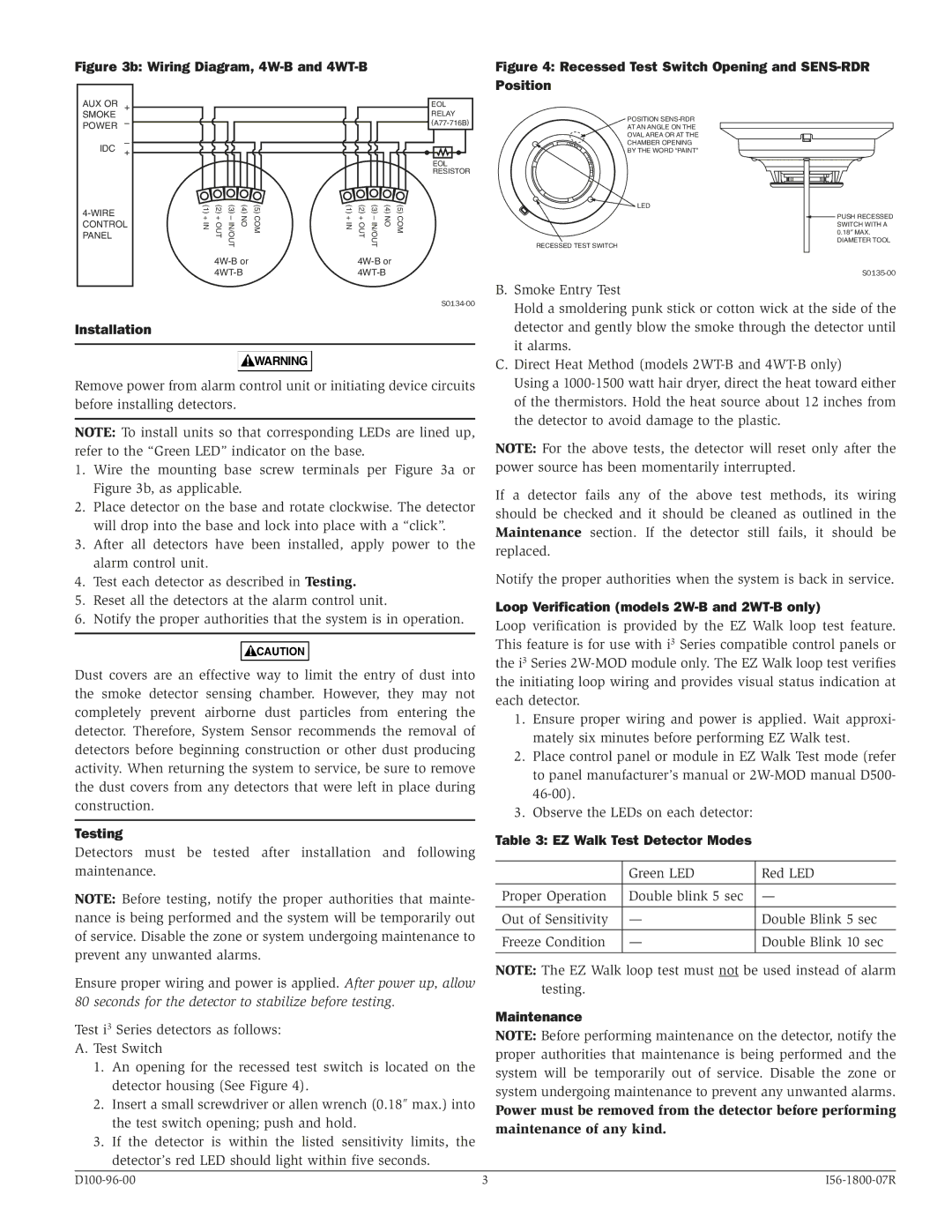

Figure 4: Recessed Test Switch Opening and SENS-RDR Position

AUX OR | + |

| EOL |

SMOKE | – |

| RELAY |

POWER |

| ||

IDC | – |

|

|

+ |

|

| |

|

|

| EOL |

|

|

| RESISTOR |

| (5) (4) (3) (2) (1) | (5) (4) (3) (2) (1) | |

| COM NO – IN/OUT + OUT + IN | COM NO – IN/OUT + OUT + IN | |

CONTROL | |||

PANEL |

| ||

|

| ||

|

|

| |

POSITION

AT AN ANGLE ON THE

OVAL AREA OR AT THE

CHAMBER OPENING

BY THE WORD “PAINT”

LED

RECESSED TEST SWITCH

![]() PUSH RECESSED SWITCH WITH A 0.18″ MAX.

PUSH RECESSED SWITCH WITH A 0.18″ MAX.

DIAMETER TOOL

Installation

![]()

![]() WARNING

WARNING

Remove power from alarm control unit or initiating device circuits before installing detectors.

NOTE: To install units so that corresponding LEDs are lined up, refer to the “Green LED” indicator on the base.

1.Wire the mounting base screw terminals per Figure 3a or Figure 3b, as applicable.

2.Place detector on the base and rotate clockwise. The detector will drop into the base and lock into place with a “click”.

3.After all detectors have been installed, apply power to the alarm control unit.

4.Test each detector as described in Testing.

5.Reset all the detectors at the alarm control unit.

6.Notify the proper authorities that the system is in operation.

![]()

![]() CAUTION

CAUTION

Dust covers are an effective way to limit the entry of dust into the smoke detector sensing chamber. However, they may not completely prevent airborne dust particles from entering the detector. Therefore, System Sensor recommends the removal of detectors before beginning construction or other dust producing activity. When returning the system to service, be sure to remove the dust covers from any detectors that were left in place during construction.

Testing

Detectors must be tested after installation and following maintenance.

NOTE: Before testing, notify the proper authorities that mainte- nance is being performed and the system will be temporarily out of service. Disable the zone or system undergoing maintenance to prevent any unwanted alarms.

Ensure proper wiring and power is applied. After power up, allow 80 seconds for the detector to stabilize before testing.

Test i3 Series detectors as follows:

A. Test Switch

1.An opening for the recessed test switch is located on the detector housing (See Figure 4).

2.Insert a small screwdriver or allen wrench (0.18″ max.) into the test switch opening; push and hold.

3.If the detector is within the listed sensitivity limits, the detector’s red LED should light within five seconds.

B.Smoke Entry Test

Hold a smoldering punk stick or cotton wick at the side of the detector and gently blow the smoke through the detector until it alarms.

C.Direct Heat Method (models

Using a

NOTE: For the above tests, the detector will reset only after the power source has been momentarily interrupted.

If a detector fails any of the above test methods, its wiring should be checked and it should be cleaned as outlined in the Maintenance section. If the detector still fails, it should be replaced.

Notify the proper authorities when the system is back in service.

Loop Verification (models 2W-B and 2WT-B only)

Loop verification is provided by the EZ Walk loop test feature. This feature is for use with i3 Series compatible control panels or the i3 Series

1.Ensure proper wiring and power is applied. Wait approxi- mately six minutes before performing EZ Walk test.

2.Place control panel or module in EZ Walk Test mode (refer to panel manufacturer’s manual or

3.Observe the LEDs on each detector:

Table 3: EZ Walk Test Detector Modes

| Green LED | Red LED |

|

|

|

Proper Operation | Double blink 5 sec | — |

|

|

|

Out of Sensitivity | — | Double Blink 5 sec |

|

|

|

Freeze Condition | — | Double Blink 10 sec |

|

|

|

NOTE: The EZ Walk loop test must not be used instead of alarm testing.

Maintenance

NOTE: Before performing maintenance on the detector, notify the proper authorities that maintenance is being performed and the system will be temporarily out of service. Disable the zone or system undergoing maintenance to prevent any unwanted alarms.

Power must be removed from the detector before performing maintenance of any kind.

3 |