DH500, Intelligent Air Duct Smoke Detector Housing specifications

The System Sensor DH500 is an advanced intelligent air duct smoke detector housing designed to effectively monitor and detect smoke within HVAC ducts. As smoke detection in air handling systems is critical to ensuring the safety of occupants, the DH500 utilizes cutting-edge technology to provide reliable performance and early warning capabilities.One of the main features of the DH500 is its intelligent detection capabilities. The device employs photoelectric sensing technology, which is well-suited for detecting the slow-burning fires that often generate more smoke than flames. This technology allows for prompt detection of smoke particles while minimizing false alarms caused by dust or other non-threatening particles. The DH500 is designed to operate efficiently in various environments, making it ideal for commercial and industrial settings.

The DH500 is equipped with a low-profile design, providing ease of installation and a more aesthetically pleasing appearance that blends seamlessly with existing ductwork. The housing is made from durable materials, ensuring long-lasting performance and resilience against environmental factors.

Another significant characteristic of the DH500 is its ability to accommodate multiple detectors. The housing can integrate with a variety of smoke detectors, allowing for installation flexibility depending on specific needs and applications. This modularity is particularly advantageous in large buildings where multiple air ducts may need simultaneous monitoring.

The device also incorporates advanced communication options, allowing for compatibility with various fire alarm control panels. This enables real-time monitoring and integration into broader building safety systems, enhancing overall emergency response capabilities. Moreover, the DH500 features an intuitive status indicator that provides visual confirmation of operational performance, making maintenance and monitoring straightforward.

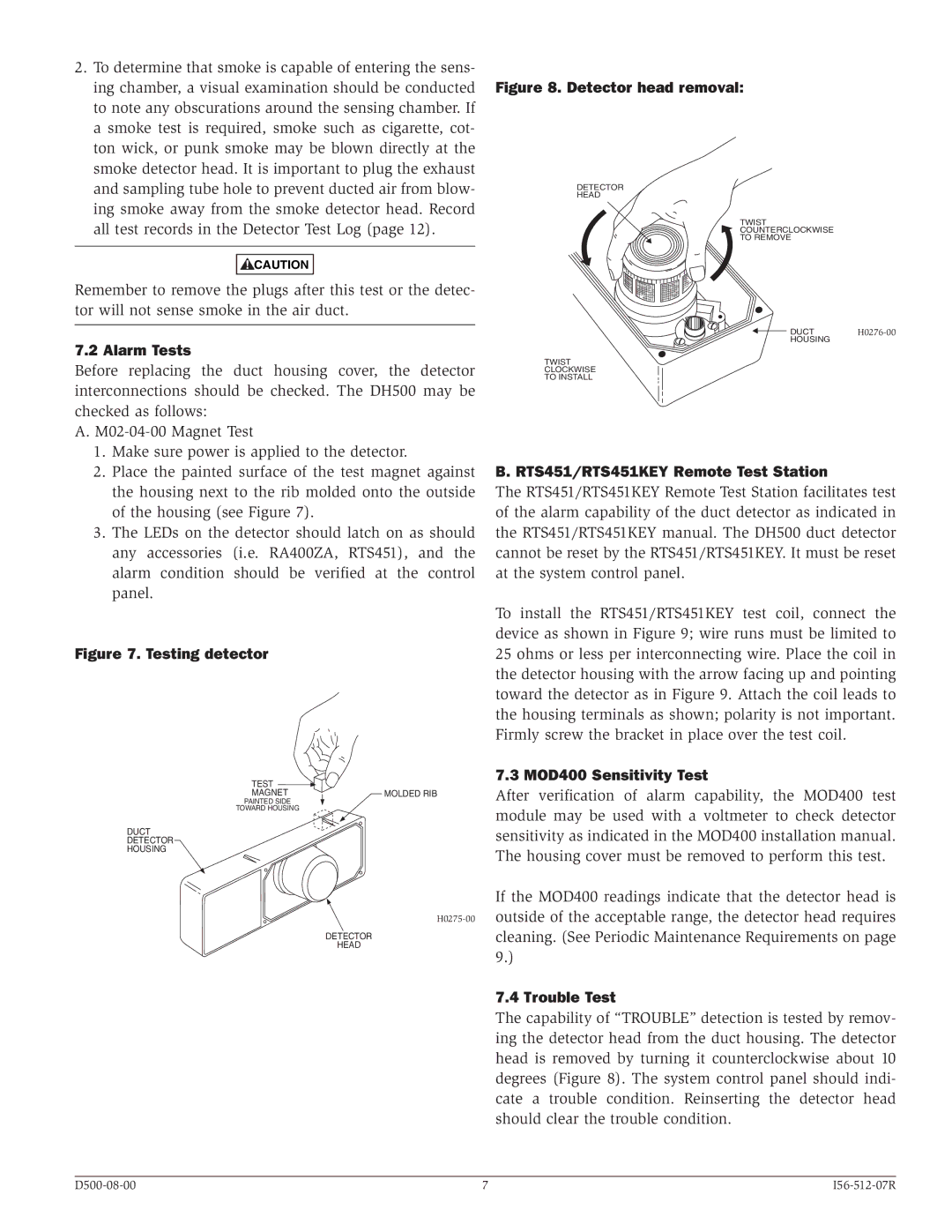

In terms of maintenance, the DH500 is designed for easy access to the smoke detectors, ensuring they can be inspected and cleaned regularly, optimizing their efficiency and longevity. Regular maintenance plays a crucial role in the reliability of smoke detection systems, and the DH500's user-friendly design supports this essential function.

In summary, the System Sensor DH500 intelligent air duct smoke detector housing stands out for its intelligent detection technology, low-profile design, compatibility with multiple detectors, and advanced communication capabilities. Its durable construction and focus on ease of maintenance further enhance its appeal for commercial and industrial applications, making it a reliable choice for effective smoke detection in air handling systems.