TOB-120,TOB-300

Lubrication and Maintenance

Owner’s Manual

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any

Your Tanaka Dealer will be happy to provide any service required to keep your Outboard Motor operating at peak efficiency.

CAUTION: Stop motor, wait for moving parts to stop and disconnect spark plug wire before attempting any lubrication or maintenance procedures.

CAUTION: DO NOT touch motor or drive parts which might be hot from operation. Allow such parts to cool before servicing unit.

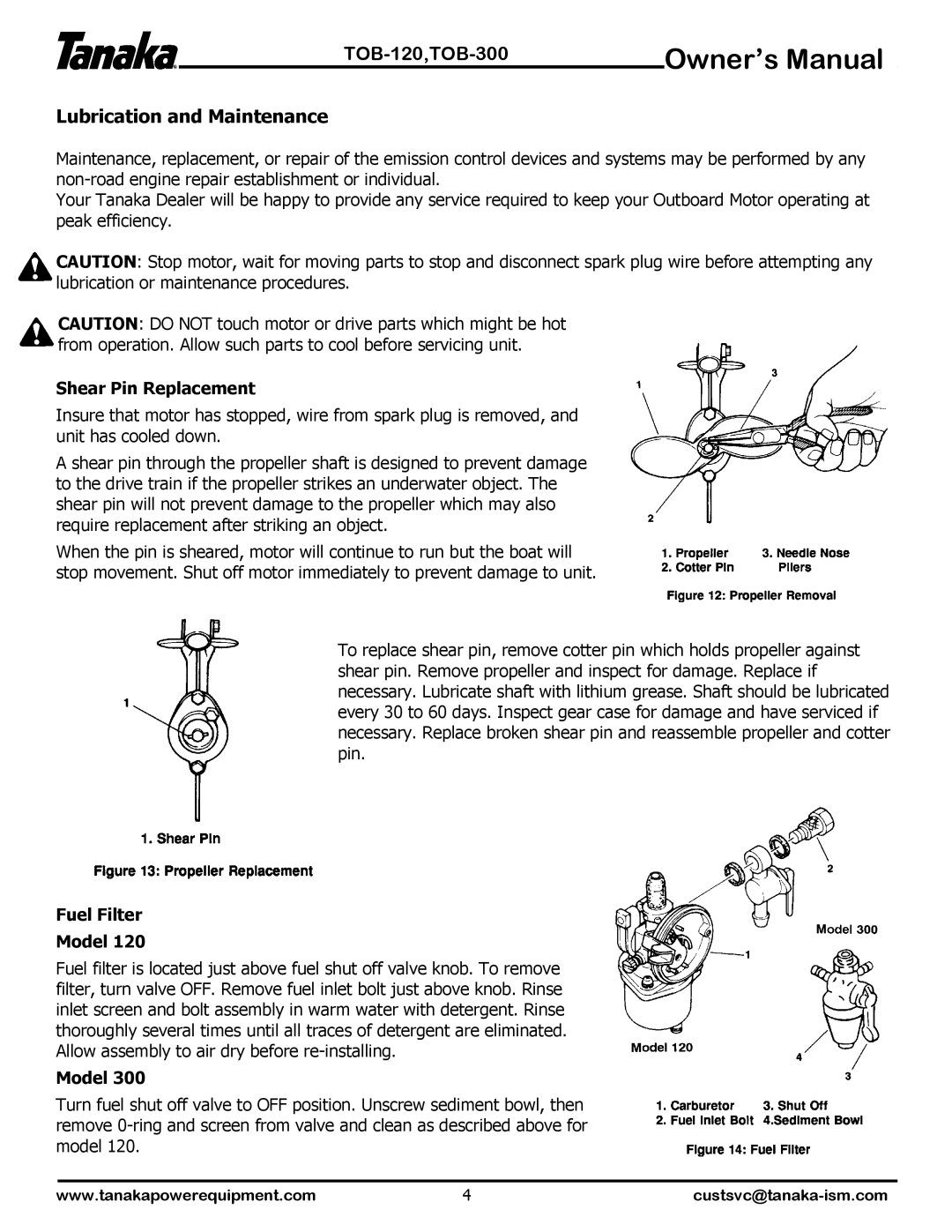

Shear Pin Replacement

Insure that motor has stopped, wire from spark plug is removed, and unit has cooled down.

A shear pin through the propeller shaft is designed to prevent damage to the drive train if the propeller strikes an underwater object. The shear pin will not prevent damage to the propeller which may also require replacement after striking an object.

When the pin is sheared, motor will continue to run but the boat will stop movement. Shut off motor immediately to prevent damage to unit.

To replace shear pin, remove cotter pin which holds propeller against shear pin. Remove propeller and inspect for damage. Replace if necessary. Lubricate shaft with lithium grease. Shaft should be lubricated every 30 to 60 days. Inspect gear case for damage and have serviced if necessary. Replace broken shear pin and reassemble propeller and cotter pin.

Fuel Filter

Model 120

Fuel filter is located just above fuel shut off valve knob. To remove filter, turn valve OFF. Remove fuel inlet bolt just above knob. Rinse inlet screen and bolt assembly in warm water with detergent. Rinse thoroughly several times until all traces of detergent are eliminated. Allow assembly to air dry before

Model 300

Turn fuel shut off valve to OFF position. Unscrew sediment bowl, then remove

www.tanakapowerequipment.com | 4 |