TOB-120,TOB-300

Motor Cooling

Owner’s Manual

The motor is air cooled, and air must circulate freely around motor and over cooling fins on cylinder head to prevent overheating.

Once a year or every one hundred (100) operating hours, more often if conditions require) clean fins and external surfaces of motor of dust, dirt and oil deposits which can contribute to improper cooling.

IMPORTANT: DO NOT operate motor with motor shroud or muffler guard removed as this will cause overheating and motor damage.

Spark Plug

Spark plug should be cleaned or replaced (if necessary) and gap reset to

.023" (.6 mm) every 100 hours of operation or yearly whichever comes first.

To clean, remove any oil or dirt from area around spark plug base, remove spark plug from motor. In a smooth running motor, plug will have brown colored electrodes. Scrape and wash with a commercial solvent. Allow to air dry. Do not sand blast clean.

NOTE: Arcing can occur if wire terminal does not fit firmly on spark plug. Reform or replace terminal as needed.

Test for faulty ignition system by removing spark plug from engine. Connect plug wire and hold plug electrode against bare metal part of motor (away from spark plug hole). Pull recoil starter rope several times. If spark jumps gap of electrode, ignition system is in good condition.

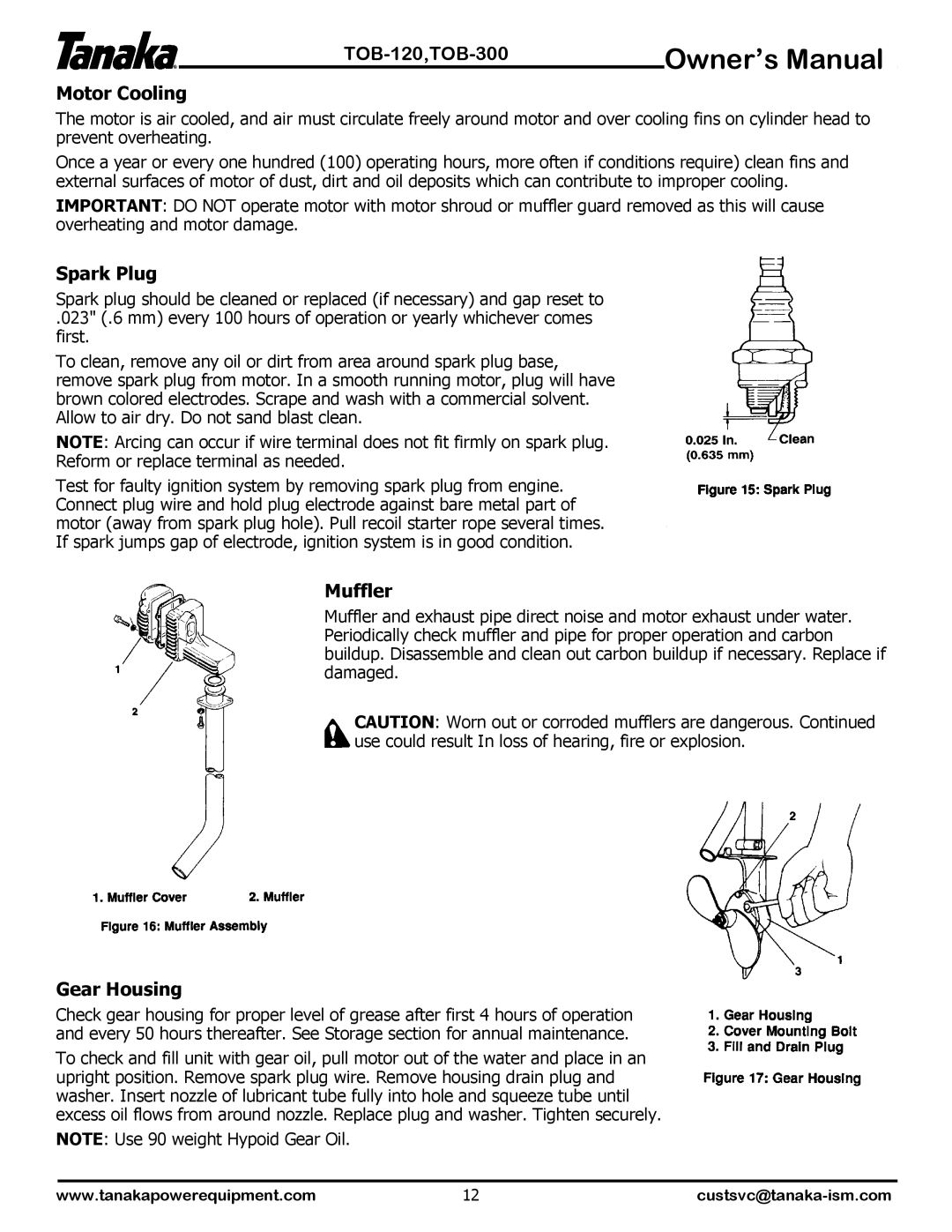

Muffler

Muffler and exhaust pipe direct noise and motor exhaust under water. Periodically check muffler and pipe for proper operation and carbon buildup. Disassemble and clean out carbon buildup if necessary. Replace if damaged.

CAUTION: Worn out or corroded mufflers are dangerous. Continued use could result In loss of hearing, fire or explosion.

Gear Housing

Check gear housing for proper level of grease after first 4 hours of operation and every 50 hours thereafter. See Storage section for annual maintenance.

To check and fill unit with gear oil, pull motor out of the water and place in an upright position. Remove spark plug wire. Remove housing drain plug and washer. Insert nozzle of lubricant tube fully into hole and squeeze tube until excess oil flows from around nozzle. Replace plug and washer. Tighten securely.

NOTE: Use 90 weight Hypoid Gear Oil.

www.tanakapowerequipment.com | 12 |