Service Manual | MX300 | |

|

|

|

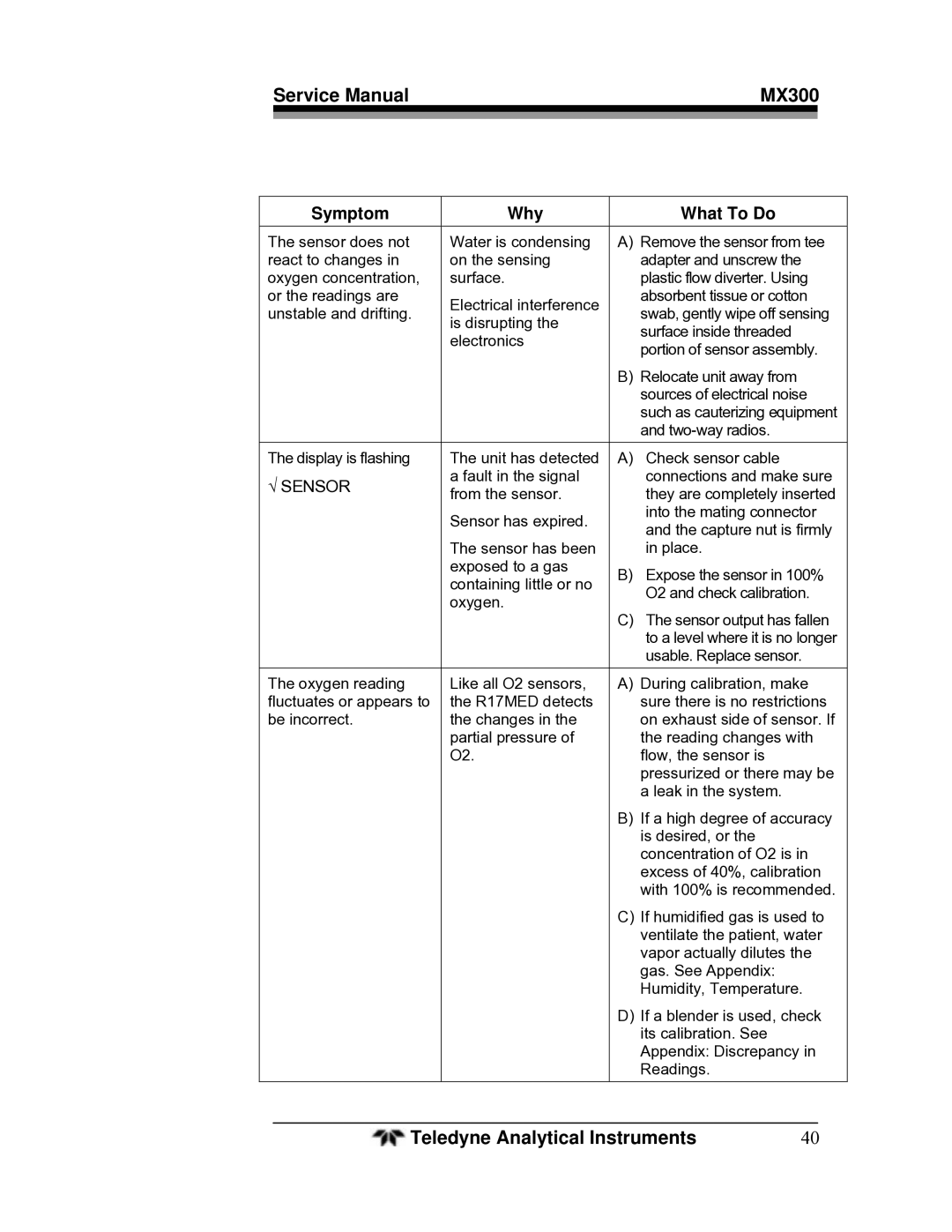

Symptom | Why | What To Do | |

The sensor does not | Water is condensing | A) Remove the sensor from tee | |

react to changes in | on the sensing | adapter and unscrew the | |

oxygen concentration, | surface. | plastic flow diverter. Using | |

or the readings are | Electrical interference | absorbent tissue or cotton | |

unstable and drifting. | swab, gently wipe off sensing | ||

is disrupting the | |||

| surface inside threaded | ||

| electronics | ||

| portion of sensor assembly. | ||

|

| ||

|

| B) Relocate unit away from | |

|

| sources of electrical noise | |

|

| such as cauterizing equipment | |

|

| and | |

The display is flashing | The unit has detected | A) Check sensor cable | |

√ SENSOR | a fault in the signal | connections and make sure | |

from the sensor. | they are completely inserted | ||

| |||

| Sensor has expired. | into the mating connector | |

| and the capture nut is firmly | ||

|

| ||

| The sensor has been | in place. | |

| exposed to a gas | B) Expose the sensor in 100% | |

| containing little or no | ||

| O2 and check calibration. | ||

| oxygen. | ||

| C) The sensor output has fallen | ||

|

| ||

|

| to a level where it is no longer | |

|

| usable. Replace sensor. | |

The oxygen reading | Like all O2 sensors, | A) During calibration, make | |

fluctuates or appears to | the R17MED detects | sure there is no restrictions | |

be incorrect. | the changes in the | on exhaust side of sensor. If | |

| partial pressure of | the reading changes with | |

| O2. | flow, the sensor is | |

|

| pressurized or there may be | |

|

| a leak in the system. | |

|

| B) If a high degree of accuracy | |

|

| is desired, or the | |

|

| concentration of O2 is in | |

|

| excess of 40%, calibration | |

|

| with 100% is recommended. | |

|

| C) If humidified gas is used to | |

|

| ventilate the patient, water | |

|

| vapor actually dilutes the | |

|

| gas. See Appendix: | |

|

| Humidity, Temperature. | |

|

| D) If a blender is used, check | |

|

| its calibration. See | |

|

| Appendix: Discrepancy in | |

|

| Readings. |

Teledyne Analytical Instruments | 40 |