135H specifications

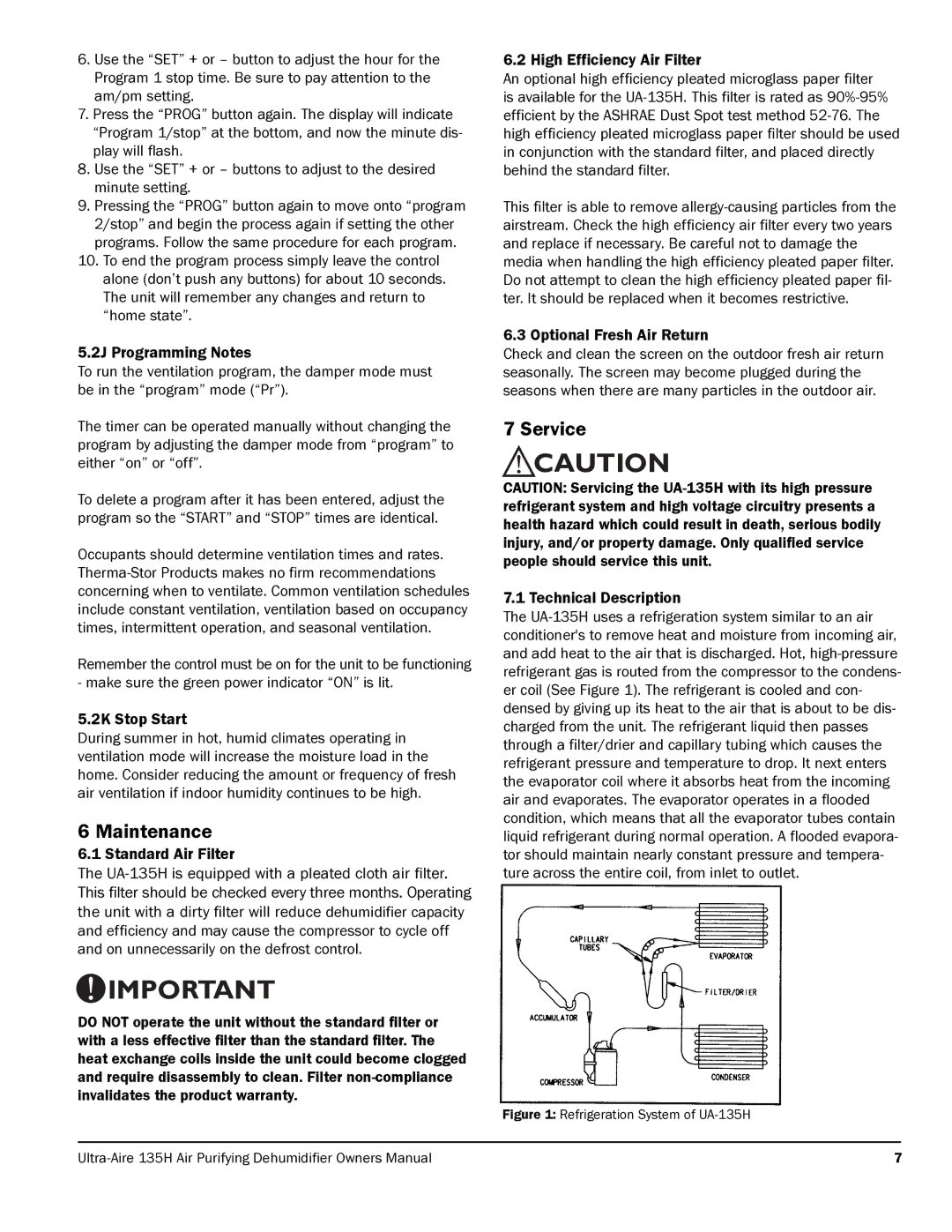

Therma-Stor Products Group has introduced the innovative 135H, a high-performance dehumidifier designed to meet the needs of various applications, including residential and commercial spaces. The 135H stands out for its advanced technology and several features that improve efficiency and user-friendliness.One of the key features of the 135H is its energy-efficient design. Utilizing a robust refrigerant system, this model ensures optimal moisture removal while maintaining low energy consumption, resulting in significant cost savings for users. The 135H is engineered to operate effectively in various humidity conditions, making it suitable for use in basements, crawl spaces, and other high-humidity environments.

The unit boasts a high-capacity water removal capability, making it one of the most effective dehumidifiers in its class. With a maximum extraction rate of up to 135 pints per day, it can tackle even the most humid situations, helping prevent mold growth, protect valuable electronics, and preserve structural integrity in homes and businesses.

In terms of user interface, the 135H features an intuitive digital control panel, allowing users to easily set their desired humidity levels. The integrated hygrometer keeps track of the current humidity, providing real-time feedback and enabling effortless adjustments. Additionally, the unit is equipped with a continuous drainage option, allowing for hassle-free operation without the need to frequently empty the water reservoir.

Durability is another hallmark of the 135H, as it is constructed from high-quality materials designed to withstand demanding environments. Its compact design allows for easy installation and portability, making it user-friendly for both residential and commercial applications.

Further enhancing the user experience, the 135H is designed with noise reduction technologies, ensuring quiet operation while maintaining high-performance levels. This feature makes it an ideal choice for living spaces, offices, or environments where minimal disruption is essential.

In conclusion, the Therma-Stor Products Group 135H dehumidifier represents a perfect blend of efficiency, technology, and user-centric design. Its powerful moisture removal capabilities, combined with energy efficiency and smart features, make it an excellent investment for anyone looking to maintain optimal humidity levels and improve indoor air quality. This model highlights Therma-Stor's commitment to providing high-quality solutions for environmental control, addressing the diverse needs of modern users.