Lubrication

WARNING: Before lubricating, repairing, or inspecting, always disengage PTO, set parking brake, stop engine and remove key to prevent unintended starting.

Engine

Refer to Engine on page 21 for instruction regarding all

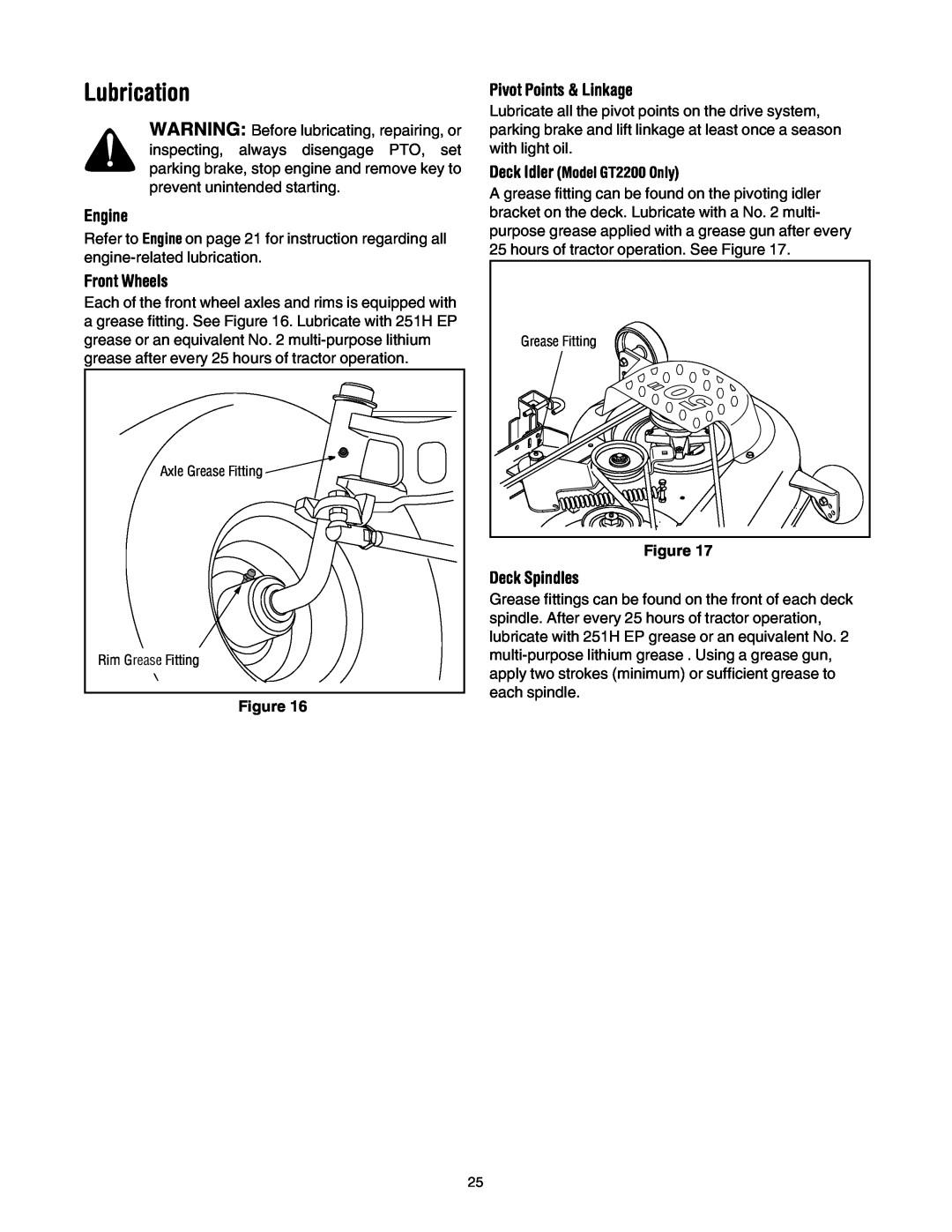

Front Wheels

Each of the front wheel axles and rims is equipped with a grease fitting. See Figure 16. Lubricate with 251H EP grease or an equivalent No. 2

Axle Grease Fitting |

Rim Grease Fitting |

Figure 16

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake and lift linkage at least once a season with light oil.

Deck Idler (Model GT2200 Only)

A grease fitting can be found on the pivoting idler bracket on the deck. Lubricate with a No. 2 multi- purpose grease applied with a grease gun after every 25 hours of tractor operation. See Figure 17.

Grease Fitting |

Figure 17

Deck Spindles

Grease fittings can be found on the front of each deck spindle. After every 25 hours of tractor operation, lubricate with 251H EP grease or an equivalent No. 2

25