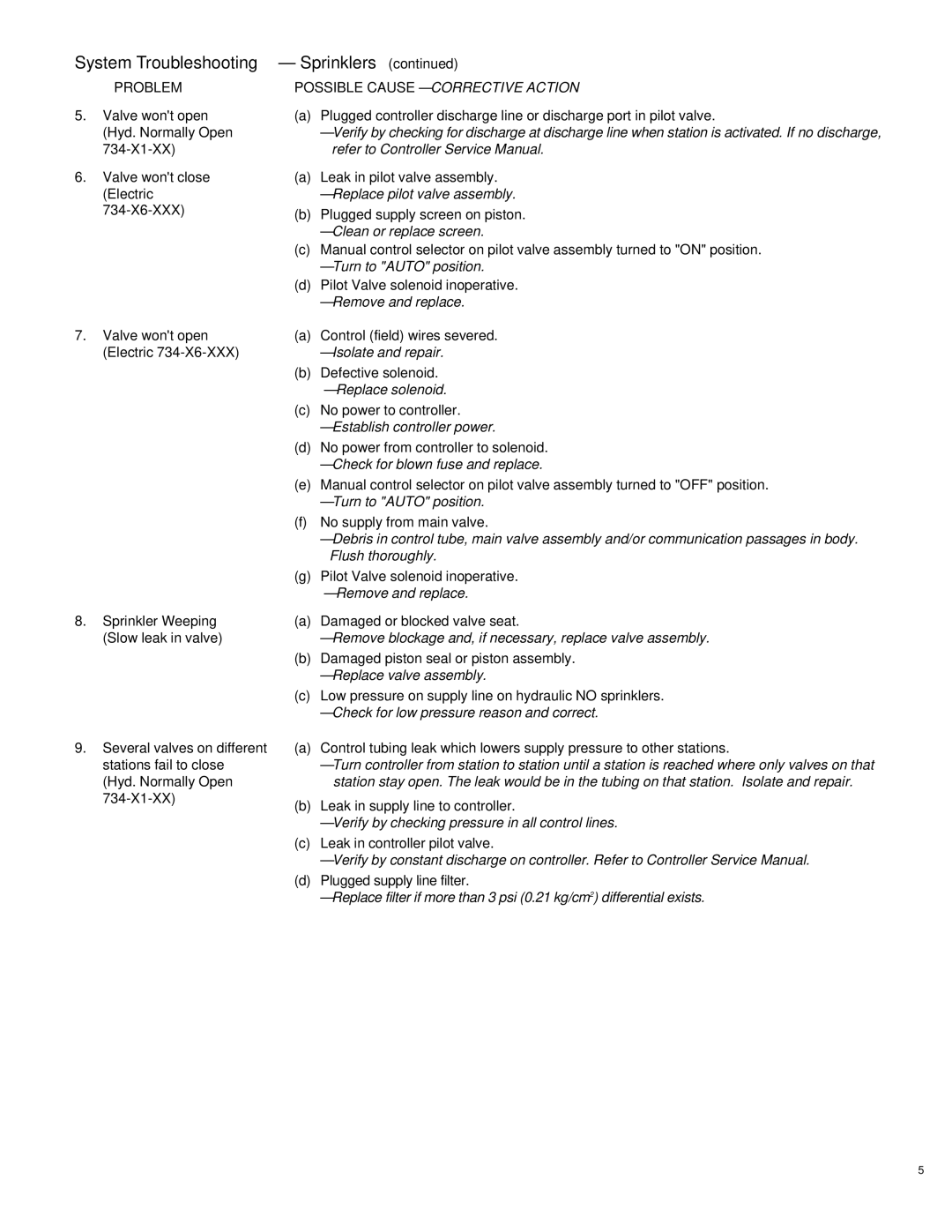

System Troubleshooting — Sprinklers (continued)

PROBLEM

5.Valve won't open (Hyd. Normally Open

6.Valve won't close (Electric

POSSIBLE CAUSE – CORRECTIVE ACTION

(a)Plugged controller discharge line or discharge port in pilot valve.

–Verify by checking for discharge at discharge line when station is activated. If no discharge, refer to Controller Service Manual.

(a)Leak in pilot valve assembly.

–Replace pilot valve assembly.

(b)Plugged supply screen on piston.

–Clean or replace screen.

(c)Manual control selector on pilot valve assembly turned to "ON" position.

–Turn to "AUTO" position.

(d)Pilot Valve solenoid inoperative.

–Remove and replace.

7. | Valve won't open | (a) | Control (field) wires severed. |

| (Electric |

| – Isolate and repair. |

|

| (b) | Defective solenoid. |

|

|

| – Replace solenoid. |

|

| (c) | No power to controller. |

|

|

| – Establish controller power. |

|

| (d) | No power from controller to solenoid. |

|

|

| – Check for blown fuse and replace. |

|

| (e) | Manual control selector on pilot valve assembly turned to "OFF" position. |

|

|

| – Turn to "AUTO" position. |

|

| (f) | No supply from main valve. |

|

|

| – Debris in control tube, main valve assembly and/or communication passages in body. |

|

|

| Flush thoroughly. |

|

| (g) | Pilot Valve solenoid inoperative. |

|

|

| – Remove and replace. |

8. | Sprinkler Weeping | (a) | Damaged or blocked valve seat. |

| (Slow leak in valve) |

| – Remove blockage and, if necessary, replace valve assembly. |

|

| (b) | Damaged piston seal or piston assembly. |

|

|

| – Replace valve assembly. |

|

| (c) | Low pressure on supply line on hydraulic NO sprinklers. |

|

|

| – Check for low pressure reason and correct. |

9.Several valves on different stations fail to close (Hyd. Normally Open

(a)Control tubing leak which lowers supply pressure to other stations.

–Turn controller from station to station until a station is reached where only valves on that station stay open. The leak would be in the tubing on that station. Isolate and repair.

(b)Leak in supply line to controller.

–Verify by checking pressure in all control lines.

(c)Leak in controller pilot valve.

–Verify by constant discharge on controller. Refer to Controller Service Manual.

(d)Plugged supply line filter.

–Replace filter if more than 3 psi (0.21 kg/cm2) differential exists.

5