Connecting Hydraulic Control Tubing

1.Route control tubing from controller to sprinkler location(s).

NOTE:

❚Leave an 18" (45.7 cm) service loop of tubing at each sprinkler to facilitate movement of sprinkler and service operations.

❚Tubing runs in excess of 1,000' (304.8 m) are not advisable due to delayed response time.

❚The valve elevation for normally open

❚The valve elevation for normally closed

❚If connecting more than one VIH sprinkler per control tubing run, refer to the chart below.

| Recommended | Maximum |

1" VIH | 3 | 5 |

1.5" VIH | 2 | 3 |

2.Flush tubing thoroughly to remove all air and debris.

3.Remove tube retainer and poly cap from tubing adapter at base of sprinkler.

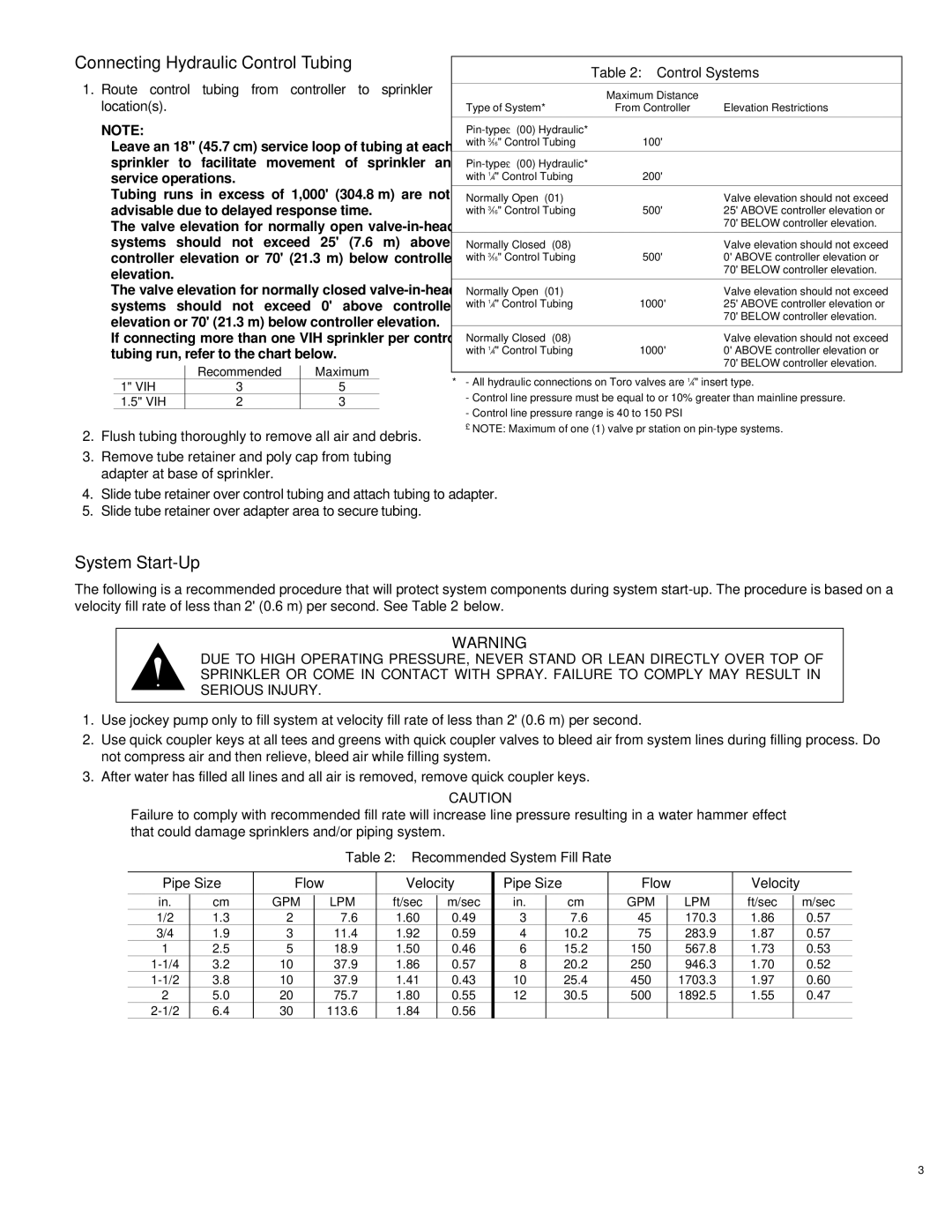

Table 2: Control Systems

| Maximum Distance |

|

Type of System* | From Controller | Elevation Restrictions |

|

|

|

|

| |

with 3⁄16" Control Tubing | 100' |

|

|

|

|

|

| |

with 1⁄4" Control Tubing | 200' |

|

|

|

|

Normally Open (01) |

| Valve elevation should not exceed |

with 3⁄16" Control Tubing | 500' | 25' ABOVE controller elevation or |

|

| 70' BELOW controller elevation. |

|

|

|

Normally Closed (08) |

| Valve elevation should not exceed |

with 3⁄16" Control Tubing | 500' | 0' ABOVE controller elevation or |

|

| 70' BELOW controller elevation. |

|

|

|

Normally Open (01) |

| Valve elevation should not exceed |

with 1⁄4" Control Tubing | 1000' | 25' ABOVE controller elevation or |

|

| 70' BELOW controller elevation. |

|

|

|

Normally Closed (08) |

| Valve elevation should not exceed |

with 1⁄4" Control Tubing | 1000' | 0' ABOVE controller elevation or |

|

| 70' BELOW controller elevation. |

*- All hydraulic connections on Toro valves are 1⁄4" insert type.

-Control line pressure must be equal to or 10% greater than mainline pressure.

-Control line pressure range is 40 to 150 PSI

£NOTE: Maximum of one (1) valve pr station on

4.Slide tube retainer over control tubing and attach tubing to adapter.

5.Slide tube retainer over adapter area to secure tubing.

System Start-Up

The following is a recommended procedure that will protect system components during system

WARNING

DUE TO HIGH OPERATING PRESSURE, NEVER STAND OR LEAN DIRECTLY OVER TOP OF SPRINKLER OR COME IN CONTACT WITH SPRAY. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY.

1.Use jockey pump only to fill system at velocity fill rate of less than 2' (0.6 m) per second.

2.Use quick coupler keys at all tees and greens with quick coupler valves to bleed air from system lines during filling process. Do not compress air and then relieve, bleed air while filling system.

3.After water has filled all lines and all air is removed, remove quick coupler keys.

CAUTION

Failure to comply with recommended fill rate will increase line pressure resulting in a water hammer effect that could damage sprinklers and/or piping system.

Table 2: Recommended System Fill Rate

Pipe Size | Flow | Velocity | Pipe Size | Flow | Velocity | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

in. | cm | GPM | LPM | ft/sec | m/sec | in. | cm | GPM | LPM | ft/sec | m/sec |

1/2 | 1.3 | 2 | 7.6 | 1.60 | 0.49 | 3 | 7.6 | 45 | 170.3 | 1.86 | 0.57 |

3/4 | 1.9 | 3 | 11.4 | 1.92 | 0.59 | 4 | 10.2 | 75 | 283.9 | 1.87 | 0.57 |

1 | 2.5 | 5 | 18.9 | 1.50 | 0.46 | 6 | 15.2 | 150 | 567.8 | 1.73 | 0.53 |

3.2 | 10 | 37.9 | 1.86 | 0.57 | 8 | 20.2 | 250 | 946.3 | 1.70 | 0.52 | |

3.8 | 10 | 37.9 | 1.41 | 0.43 | 10 | 25.4 | 450 | 1703.3 | 1.97 | 0.60 | |

2 | 5.0 | 20 | 75.7 | 1.80 | 0.55 | 12 | 30.5 | 500 | 1892.5 | 1.55 | 0.47 |

6.4 | 30 | 113.6 | 1.84 | 0.56 |

|

|

|

|

|

| |

3