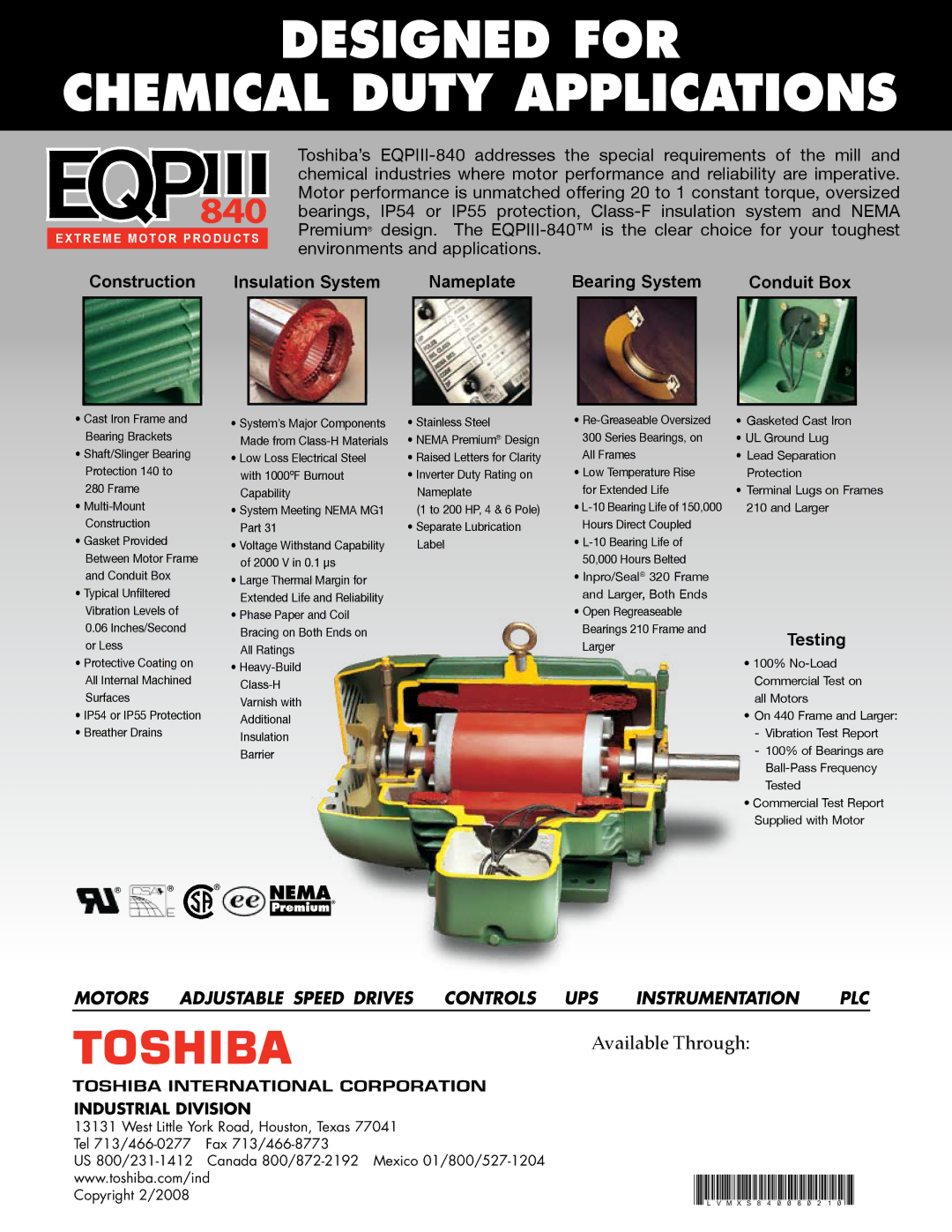

Designed for

chemical duty applications

Toshiba’s

EXTREME MOTOR PRODUCTS Premium® design. The

Construction | Insulation System | Nameplate | Bearing System | Conduit Box | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Cast Iron Frame and Bearing Brackets

•Shaft/Slinger Bearing Protection 140 to 280 Frame

•

•Gasket Provided Between Motor Frame and Conduit Box

•Typical Unfiltered Vibration Levels of

0.06Inches/Second or Less

•Protective Coating on All Internal Machined Surfaces

•IP54 or IP55 Protection

•Breather Drains

•System’s Major Components Made from

•Low Loss Electrical Steel with 1000ºF Burnout Capability

•System Meeting NEMA MG1 Part 31

•Voltage Withstand Capability of 2000 V in 0.1 µs

•Large Thermal Margin for Extended Life and Reliability

•Phase Paper and Coil Bracing on Both Ends on All Ratings

•

•Stainless Steel

•NEMA Premium® Design

•Raised Letters for Clarity

•Inverter Duty Rating on Nameplate

(1 to 200 HP, 4 & 6 Pole)

•Separate Lubrication Label

•Re-Greaseable Oversized 300 Series Bearings, on All Frames

•Low Temperature Rise for Extended Life

•

•

•Inpro/Seal® 320 Frame and Larger, Both Ends

•Open Regreaseable Bearings 210 Frame and Larger

•Gasketed Cast Iron

•UL Ground Lug

•Lead Separation Protection

•Terminal Lugs on Frames 210 and Larger

Testing

•100%

•On 440 Frame and Larger:

-Vibration Test Report

-100% of Bearings are

•Commercial Test Report Supplied with Motor

MOTORS ADJUSTABLE SPEED DRIVES CONTROLS UPS | INSTRUMENTATION | PLC |

INDUSTRIAL DIVISION

13131 West Little York Road, Houston, Texas 77041 Tel

US

Copyright 2/2008

Available Through:

*LVMXS840080210*