Installer’s Guide

2BASEPAN TAB REMOVAL

ture to prevent excess roof

4.The top discharge area must be unrestricted for at least five (5) feet above the unit.

5.When the outdoor unit is mounted on a roof, be sure the roof will support the unit’s weight. Properly selected isolation is recommended to prevent transmission to the building structure.

6.The maximum length of refrigerant lines from outdoor to indoor unit should NOT exceed sixty (60) feet.

7.If outdoor unit is mounted above the air handler, maxi- mum lift should not exceed sixty (60) feet (suction line). If air handler is mounted above condensing unit, maxi- mum lift should not exceed sixty (60) feet (liquid line).

8.Locate and install indoor coil or air handler in accor- dance with instruction included with that unit.

C.ACCUTRON™ FLOW CONTROL VALVE

If the indoor unit System Refrigerant Flow control is an Accutron™ orifice and check valve assembly, an orifice size change may be necessary.

The outdoor model determines the required orifice size. Check the listed orifice size on nameplate of the selected outdoor model. If the indoor unit is factory shipped with a different orifice size, the orifice must be changed to obtain system rated performance.

IMPORTANT:

The outdoor unit is shipped with the proper size orifice and a

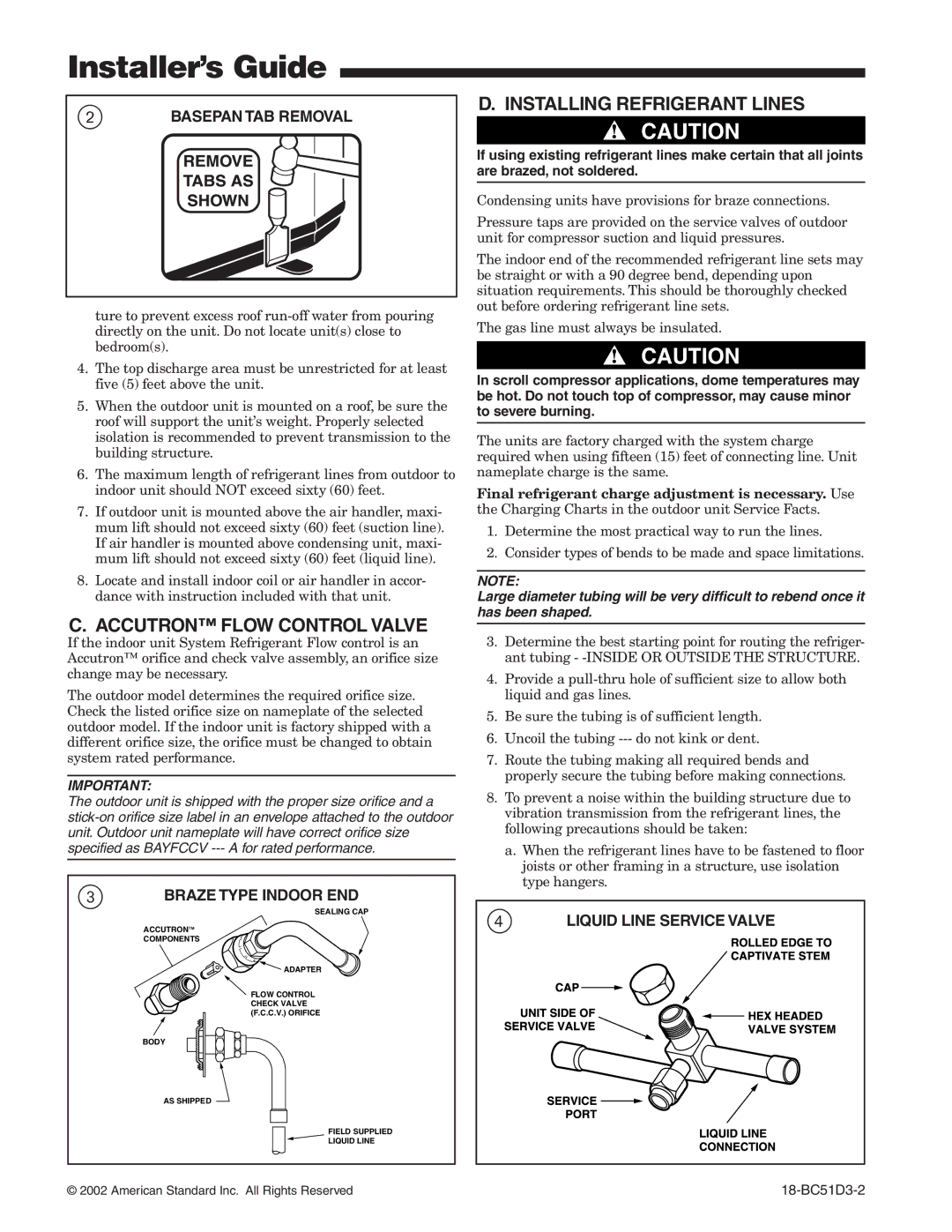

3BRAZE TYPE INDOOR END

SEALING CAP

ACCUTRONTM

COMPONENTS

![]() ADAPTER

ADAPTER

FLOW CONTROL CHECK VALVE (F.C.C.V.) ORIFICE

BODY

AS SHIPPED

FIELD SUPPLIED

LIQUID LINE

D. INSTALLING REFRIGERANT LINES

▲! CAUTION

If using existing refrigerant lines make certain that all joints are brazed, not soldered.

Condensing units have provisions for braze connections.

Pressure taps are provided on the service valves of outdoor unit for compressor suction and liquid pressures.

The indoor end of the recommended refrigerant line sets may be straight or with a 90 degree bend, depending upon situation requirements. This should be thoroughly checked out before ordering refrigerant line sets.

The gas line must always be insulated.

▲! CAUTION

In scroll compressor applications, dome temperatures may be hot. Do not touch top of compressor, may cause minor to severe burning.

The units are factory charged with the system charge required when using fifteen (15) feet of connecting line. Unit nameplate charge is the same.

Final refrigerant charge adjustment is necessary. Use the Charging Charts in the outdoor unit Service Facts.

1.Determine the most practical way to run the lines.

2.Consider types of bends to be made and space limitations.

NOTE:

Large diameter tubing will be very difficult to rebend once it has been shaped.

3.Determine the best starting point for routing the refriger- ant tubing -

4.Provide a

5.Be sure the tubing is of sufficient length.

6.Uncoil the tubing

7.Route the tubing making all required bends and properly secure the tubing before making connections.

8.To prevent a noise within the building structure due to vibration transmission from the refrigerant lines, the following precautions should be taken:

a.When the refrigerant lines have to be fastened to floor joists or other framing in a structure, use isolation type hangers.

4LIQUID LINE SERVICE VALVE

© 2002 American Standard Inc. All Rights Reserved |