ASSEMBLY INSTRUCTIONS FOR 29234

![]()

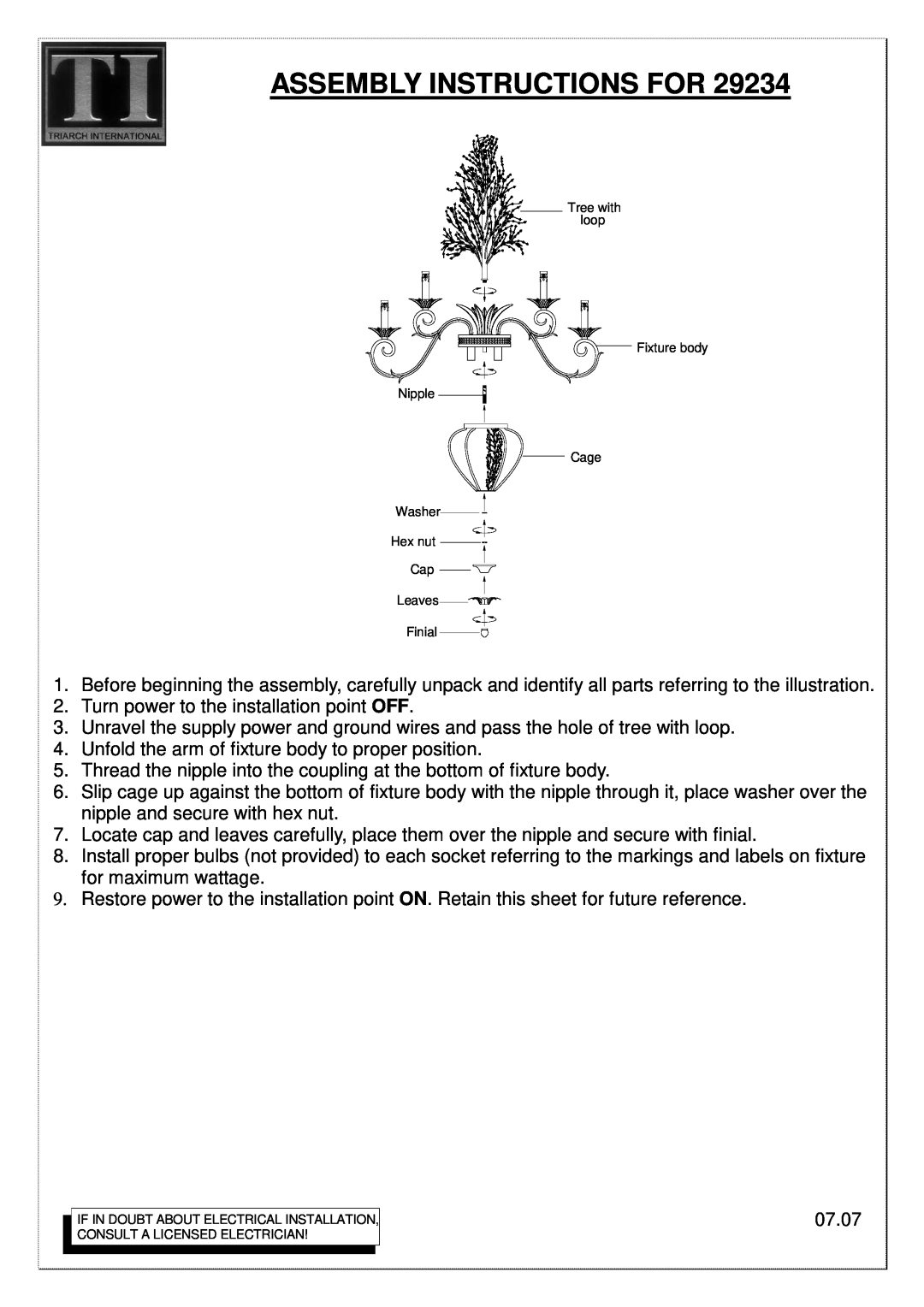

![]() Tree with

Tree with ![]()

![]()

![]() loop

loop

![]()

![]() Fixture body

Fixture body

Nipple

Cage

Washer

Hex nut

Cap

Leaves![]()

![]()

![]()

![]()

![]()

![]()

Finial

1.Before beginning the assembly, carefully unpack and identify all parts referring to the illustration.

2.Turn power to the installation point OFF.

3.Unravel the supply power and ground wires and pass the hole of tree with loop.

4.Unfold the arm of fixture body to proper position.

5.Thread the nipple into the coupling at the bottom of fixture body.

6.Slip cage up against the bottom of fixture body with the nipple through it, place washer over the nipple and secure with hex nut.

7.Locate cap and leaves carefully, place them over the nipple and secure with finial.

8.Install proper bulbs (not provided) to each socket referring to the markings and labels on fixture for maximum wattage.

9.Restore power to the installation point ON. Retain this sheet for future reference.

IF IN DOUBT ABOUT ELECTRICAL INSTALLATION, CONSULT A LICENSED ELECTRICIAN!

07.07