Application Guide

Match Battery Amp-Hour Capacity to Your Application

Select a battery or system of batteries that will provide your Inverter with proper DC voltage and an adequate

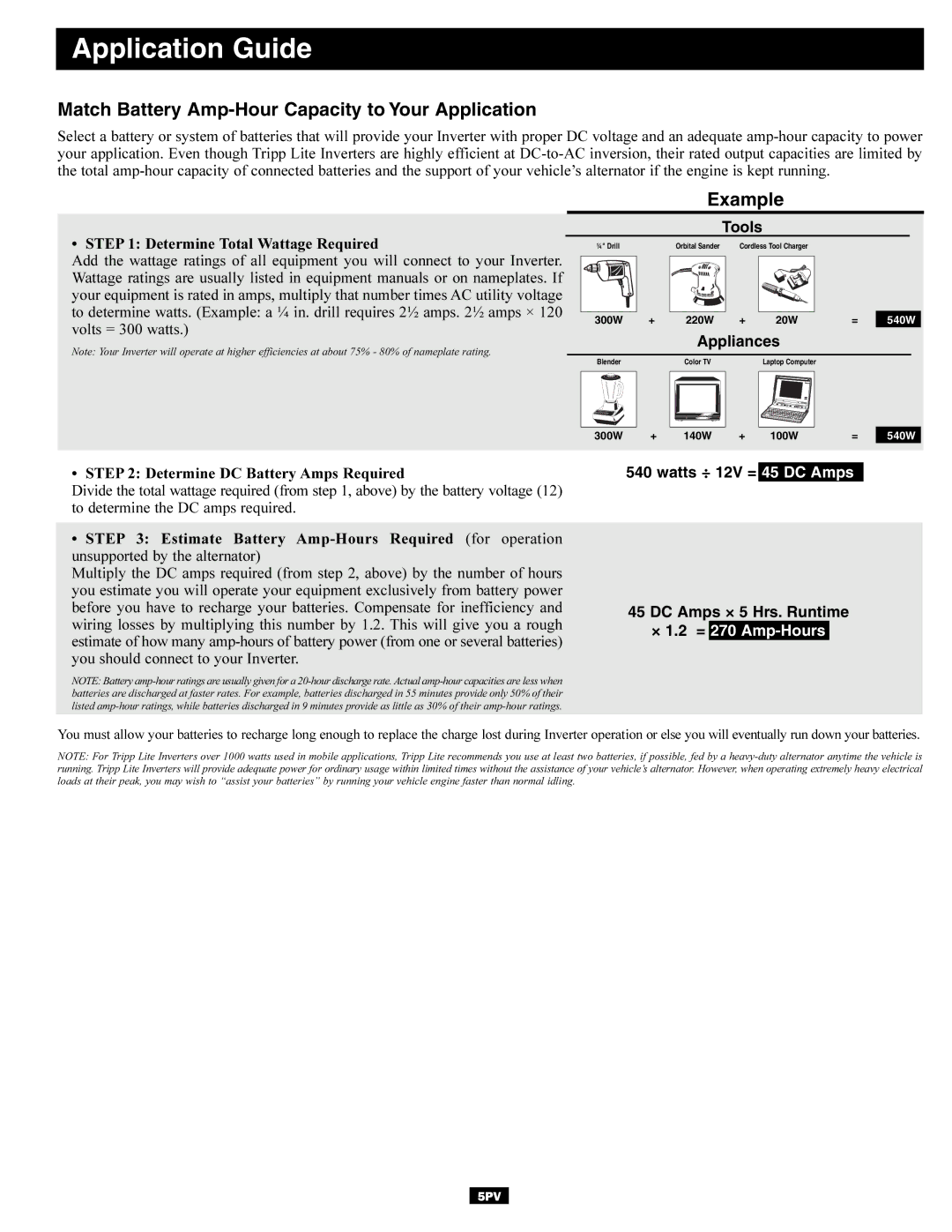

Example

• STEP 1: Determine Total Wattage Required

Add the wattage ratings of all equipment you will connect to your Inverter. Wattage ratings are usually listed in equipment manuals or on nameplates. If your equipment is rated in amps, multiply that number times AC utility voltage to determine watts. (Example: a ¼ in. drill requires 2½ amps. 2½ amps × 120 volts = 300 watts.)

Note: Your Inverter will operate at higher efficiencies at about 75% - 80% of nameplate rating.

Tools

¼" Drill | Orbital Sander | Cordless Tool Charger |

300W | + | 220W | + | 20W | = | 540W |

|

| Appliances |

|

| ||

Blender |

| Color TV |

| Laptop Computer |

|

|

300W | + | 140W | + | 100W | = | 540W |

• STEP 2: Determine DC Battery Amps Required

Divide the total wattage required (from step 1, above) by the battery voltage (12) to determine the DC amps required.

•STEP 3: Estimate Battery

Multiply the DC amps required (from step 2, above) by the number of hours you estimate you will operate your equipment exclusively from battery power before you have to recharge your batteries. Compensate for inefficiency and wiring losses by multiplying this number by 1.2. This will give you a rough estimate of how many

NOTE: Battery

540 watts ÷ 12V = 45 DC Amps

45 DC Amps × 5 Hrs. Runtime

× 1.2 = 270 Amp-Hours

You must allow your batteries to recharge long enough to replace the charge lost during Inverter operation or else you will eventually run down your batteries.

NOTE: For Tripp Lite Inverters over 1000 watts used in mobile applications, Tripp Lite recommends you use at least two batteries, if possible, fed by a

5PV