| Section 2: Assembly | 9 |

|

|

|

|

|

|

STEP 6: CHECK LEVEL OF TRANSMISSION GEAR OIL

The transmission was filled with gear oil at the factory. However, you should check the gear oil level at this time to make cer- tain it is correct.

IMPORTANT: Do not operate the tiller if the gear oil level is low. Doing so will result in severe damage to the transmis- sion components.

1.With the tiller on level ground, pull the Depth Regulator Lever (FF, Fig.

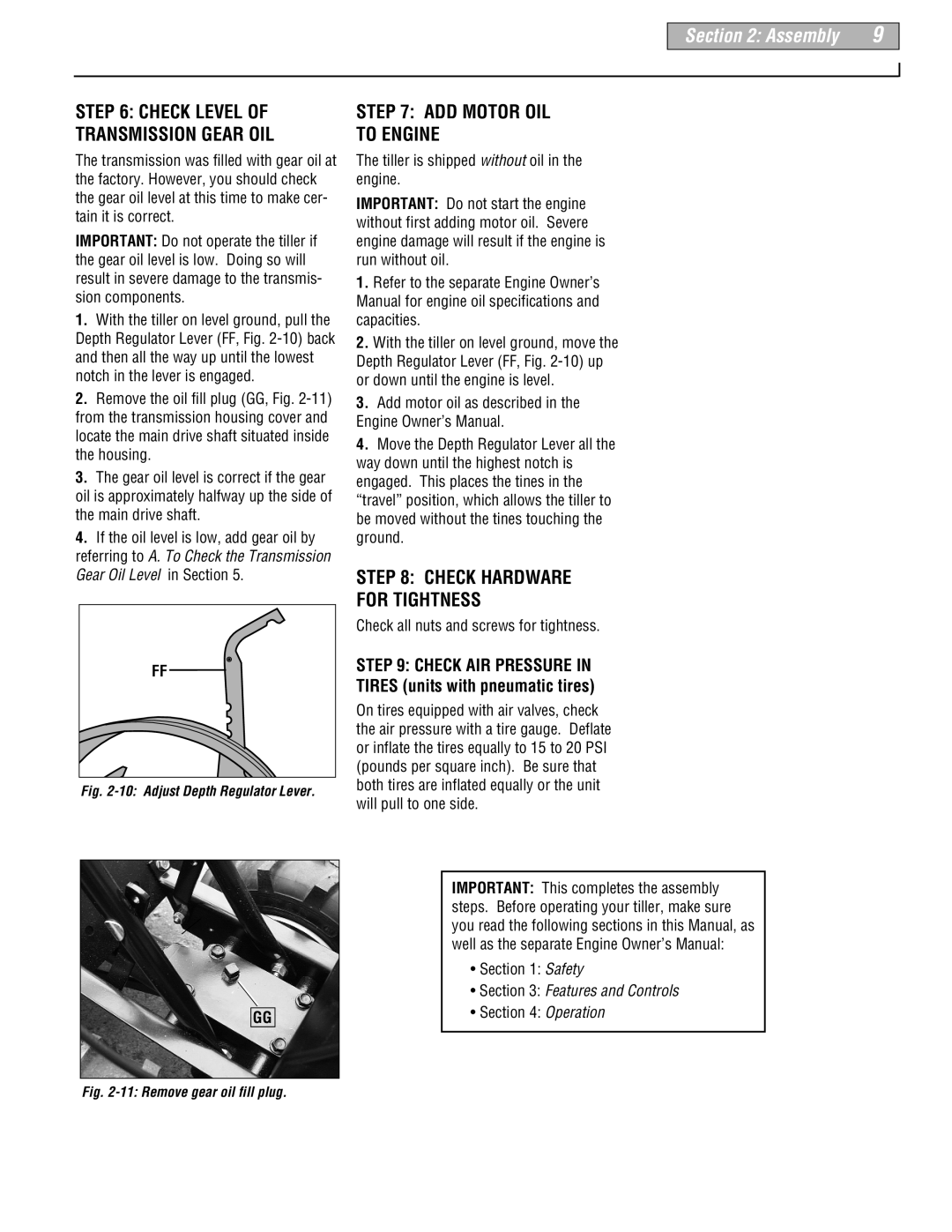

2.Remove the oil fill plug (GG, Fig.

3.The gear oil level is correct if the gear oil is approximately halfway up the side of the main drive shaft.

4.If the oil level is low, add gear oil by referring to A. To Check the Transmission Gear Oil Level in Section 5.

FF

Fig. 2-10: Adjust Depth Regulator Lever.

GG

STEP 7: ADD MOTOR OIL

TO ENGINE

The tiller is shipped without oil in the engine.

IMPORTANT: Do not start the engine without first adding motor oil. Severe engine damage will result if the engine is run without oil.

1.Refer to the separate Engine Owner’s Manual for engine oil specifications and capacities.

2.With the tiller on level ground, move the Depth Regulator Lever (FF, Fig.

3.Add motor oil as described in the Engine Owner’s Manual.

4.Move the Depth Regulator Lever all the way down until the highest notch is engaged. This places the tines in the “travel” position, which allows the tiller to be moved without the tines touching the ground.

STEP 8: CHECK HARDWARE

FOR TIGHTNESS

Check all nuts and screws for tightness.

STEP 9: CHECK AIR PRESSURE IN

TIRES (units with pneumatic tires)

On tires equipped with air valves, check the air pressure with a tire gauge. Deflate or inflate the tires equally to 15 to 20 PSI (pounds per square inch). Be sure that both tires are inflated equally or the unit will pull to one side.

IMPORTANT: This completes the assembly steps. Before operating your tiller, make sure you read the following sections in this Manual, as well as the separate Engine Owner’s Manual:

•Section 1: Safety

•Section 3: Features and Controls

•Section 4: Operation