SECTION2: ASSEMBLY

WARNING: To prevent

personal injury or property damage,do not start the engine until all assemblysteps are complete andyou have read and understandthe safety and operating instructions in this manual.

INTRODUCTION

Carefully follow these assemblysteps to correctly prepareyour tiller for use. It is recommendedthatyou readthis Sectionin its entirety before beginning assembly.

NOTE: Various rifler models are presented in this Manual. Use only the information appropriate for your tiller model. Engine styles vary by model, Your engine may appear differently than those illustrated in this manual.

INSPECTUNIT

Inspect the unit and carton for damageim- mediatelyafter delivery.Contactthe carrier (trucking company) if you find or suspect damage. Inform them of the damageand request instructions for filing a claim. To protect your rights, put your claim in writ- ing and mail a copyto the carrier within 15 days after the unit has beendelivered.

TOOLS/ MATERIALSNEEDED

(2) 1/2"

(2) 9/16"

(1) 3/8"

(1)Largeadjustable wrench (Models 644A only)

(1) Scissors (to trim plastic ties)

(1) Ruler (for belt tension check)

(1)Block of wood (to support tiller when removing wheels)

(1)Tire pressure gauge (for models with pneumatic tires)

(1) Cleanoil funnel

(1)Motor oil. Referto the EngineOwner's Manualfor oil specificationsand quantity required.

* Adjustable wrenches may be used.

ASSEMBLYSTEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE:While unpacking, do not severely bend any control cables.

1.The tiller weighs approximately 133 Ibs. Do not attempt to remove it from the ship- ping platform until instructed to do so in these Assembly steps.

2.Removeany packagingmaterial from

the carton. Removeany staples from the bottom of the carton and removethe car- ton from the shipping platform.

3.Removeall unassembled parts andthe separatehardware bag from the carton. Checkthat you havethe items listed in the Loose Parts List (contactyour local dealer or the factory items are missing or dam- aged).

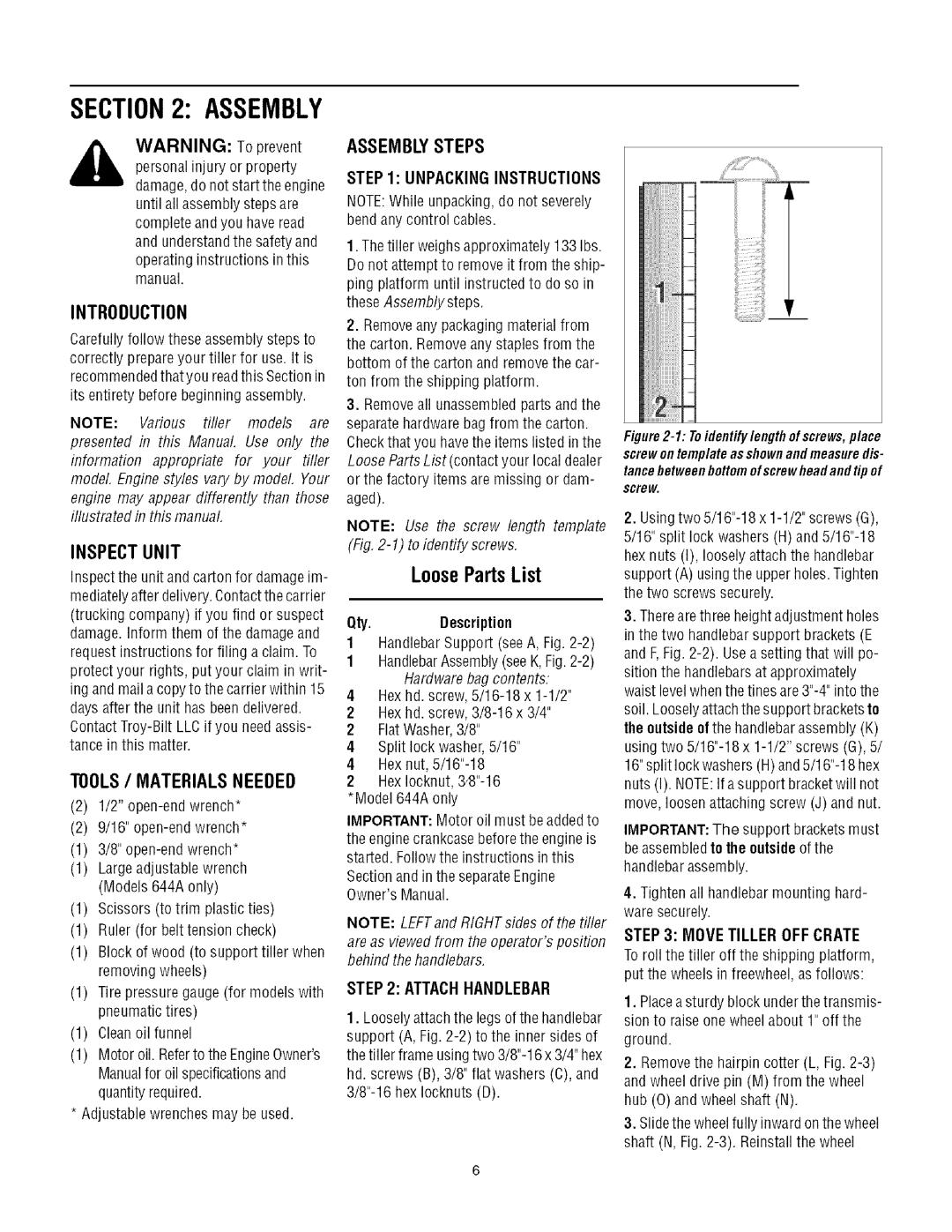

NOTE: Use the screw length template (Fig,

LooseParts List

Qty.Description

1HandlebarSupport (seeA, Fig.

1HandlebarAssembly(seeK,

4Hexhd. screw,

2Hexhd. screw,

2 FlatWasher,3/8"

4Split lock washer,5/16"

4Hex nut,

2HexIocknut,

IMPORTANT: Motor oil must beaddedto

the enginecrankcasebefore the engine is started. Followthe instructions inthis

Sectionand in the separateEngine Owner'sManual.

NOTE: LEFTand RIGHTsides of the tiller

are as viewed from the operator's position behind the handlebars.

STEP 2: ATTACH HANDLEBAR

1.Looselyattachthe legs of the handlebar support (A, Fig.

_iiii

Figure2-1: Toidentifylengthofscrews,place screwontemplateasshownandmeasuredis- tancebetweenbottomofscrewheadandtip of

screw.

2.Usingtwo

3.Therearethree height adjustment holes in the two handlebar support brackets (E and F,Fig.

the outsideofthe handlebarassembly (K) using two

IMPORTANT: The support bracketsmust beassembled to the outsideof the handlebarassembly.

4.Tightenall handlebarmounting hard- ware securely.

STEP 3: MOVE TILLER OFF CRATE To roll the tiller off the shipping platform, put the wheels in freewheel, as follows:

1.Placeasturdy block underthe transmis- sion to raise one wheel about 1" off the

ground.

2, Removethe hairpin cotter (L, Fig.

3.Slidethe wheelfully inward onthe wheel shaft (N, Fig.