Maintenance (continued)

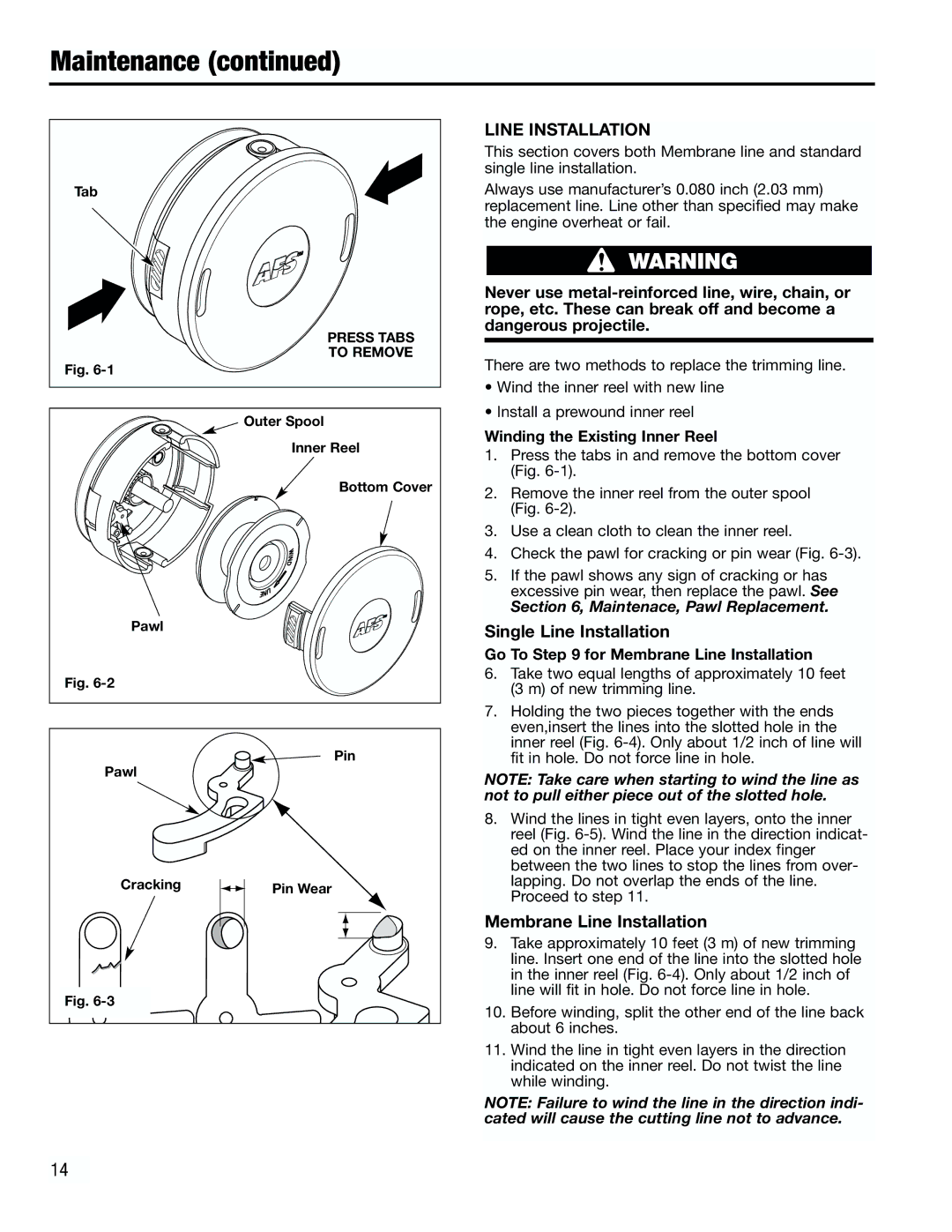

Tab |

PRESS TABS |

TO REMOVE |

Fig. |

Outer Spool

Inner Reel

Bottom Cover

Pawl |

|

Fig. |

|

Pawl | Pin |

| |

Cracking | Pin Wear |

| |

Fig. |

|

LINE INSTALLATION

This section covers both Membrane line and standard single line installation.

Always use manufacturer’s 0.080 inch (2.03 mm) replacement line. Line other than specified may make the engine overheat or fail.

Never use

There are two methods to replace the trimming line.

•Wind the inner reel with new line

•Install a prewound inner reel

Winding the Existing Inner Reel

1.Press the tabs in and remove the bottom cover (Fig.

2.Remove the inner reel from the outer spool (Fig.

3.Use a clean cloth to clean the inner reel.

4.Check the pawl for cracking or pin wear (Fig.

5.If the pawl shows any sign of cracking or has excessive pin wear, then replace the pawl. See

Section 6, Maintenace, Pawl Replacement.

Single Line Installation

Go To Step 9 for Membrane Line Installation

6.Take two equal lengths of approximately 10 feet (3 m) of new trimming line.

7.Holding the two pieces together with the ends even,insert the lines into the slotted hole in the inner reel (Fig.

NOTE: Take care when starting to wind the line as not to pull either piece out of the slotted hole.

8.Wind the lines in tight even layers, onto the inner reel (Fig.

Membrane Line Installation

9.Take approximately 10 feet (3 m) of new trimming line. Insert one end of the line into the slotted hole in the inner reel (Fig.

10.Before winding, split the other end of the line back about 6 inches.

11.Wind the line in tight even layers in the direction indicated on the inner reel. Do not twist the line while winding.

NOTE: Failure to wind the line in the direction indi- cated will cause the cutting line not to advance.

14