True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

TEMPERATURE

•Correct temperature is a key factor to consider in storing and dispensing draft beer. Too cool or too warm may cause flavor loss, off taste and dispensing problems.

Helpful Hints on Controlling Temperature

•Keep a thermometer handy

•Monitor temperature of draft in your cooler and at the tap

•Keep cooler door closed as much as possible to avoid temperature fluctuation

•Regular maintenance of refrigeration equipment is recommended

PRESSURE

Dispensing pressures differ according to:

•The type of draft dispensing system

•The length of draft dispensing line

•The actual product - some require more, some require less

•The temperature of the product

•The pressurizing agent: air pressure, CO2 or special blended gases.

Helpful Hints On Maintaining The Correct Pressure:

•Know which pressurizing agent to use on which product and why.

•Monitor your regulators to ensure applied pressure remains constant

•Keep equipment in good repair

TAPPING

Do not agitate the kegs unnecessarily. If excessive agitation occurs allow kegs to settle for 1 to 2 hours before tapping.

Prior to tapping the keg, ensure that all beer faucet in the serving location are in the off position. Completely remove the dust cover (identification cap) from the keg.

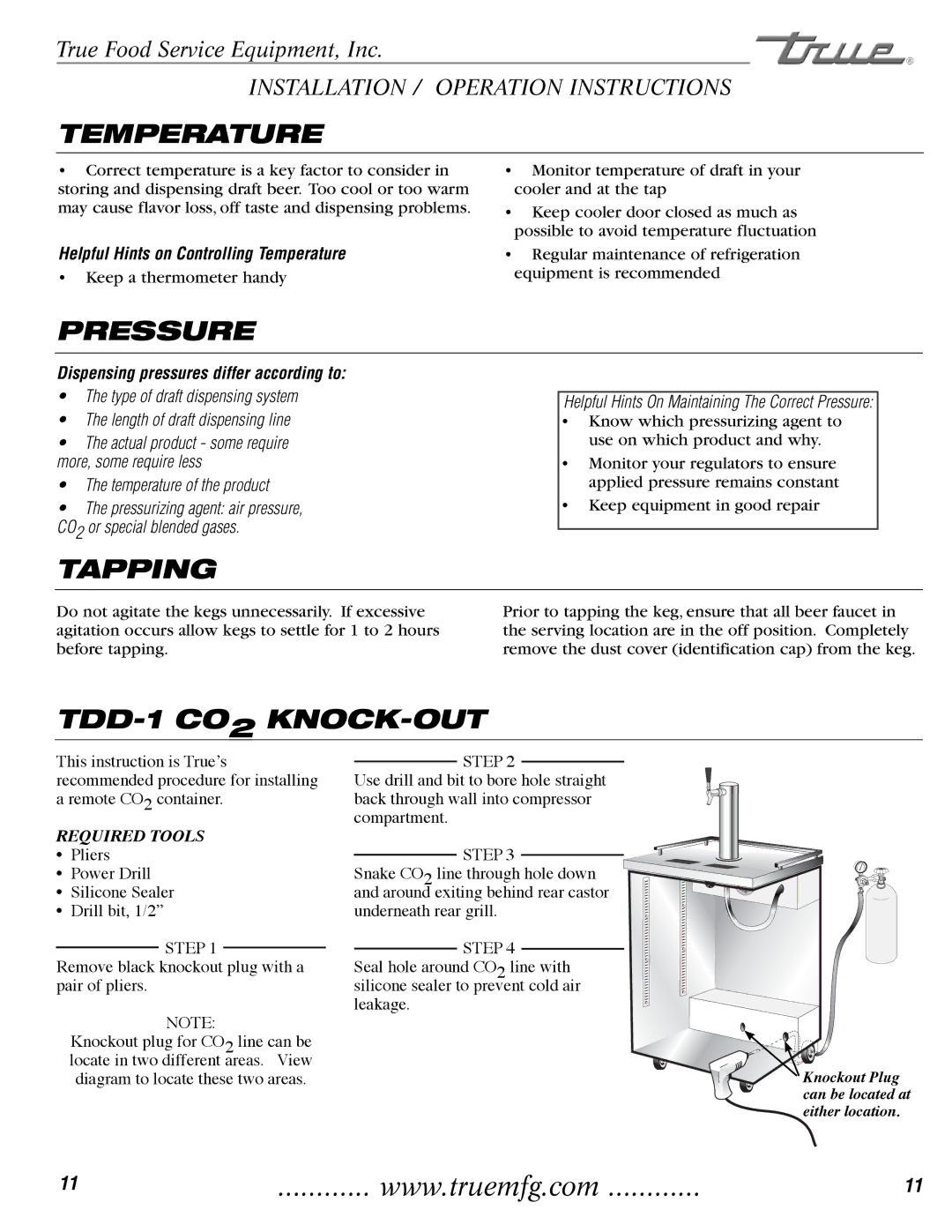

TDD-1 CO2 KNOCK-OUT

This instruction is True’s recommended procedure for installing a remote CO2 container.

REQUIRED TOOLS

•Pliers

•Power Drill

•Silicone Sealer

•Drill bit, 1/2”

STEP 1

Remove black knockout plug with a pair of pliers.

NOTE:

Knockout plug for CO2 line can be locate in two different areas. View diagram to locate these two areas.

STEP 2

Use drill and bit to bore hole straight back through wall into compressor compartment.

STEP 3 ![]()

![]()

![]()

![]()

![]() Snake CO2 line through hole down

Snake CO2 line through hole down ![]()

![]() and around exiting behind rear castor

and around exiting behind rear castor ![]()

![]()

![]() underneath rear grill.

underneath rear grill.![]()

![]()

![]()

STEP 4

Seal hole around CO2 line with silicone sealer to prevent cold air leakage.

8 | 3 |

| 4 |

| 5 |

Knockout Plug can be located at either location.

11 | www.truemfg.com | 11 |