True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

LOCATING

TOOLS REQUIRED:

•Phillips screw driver

•3/8” socket or 3/8” wrench

Step 2

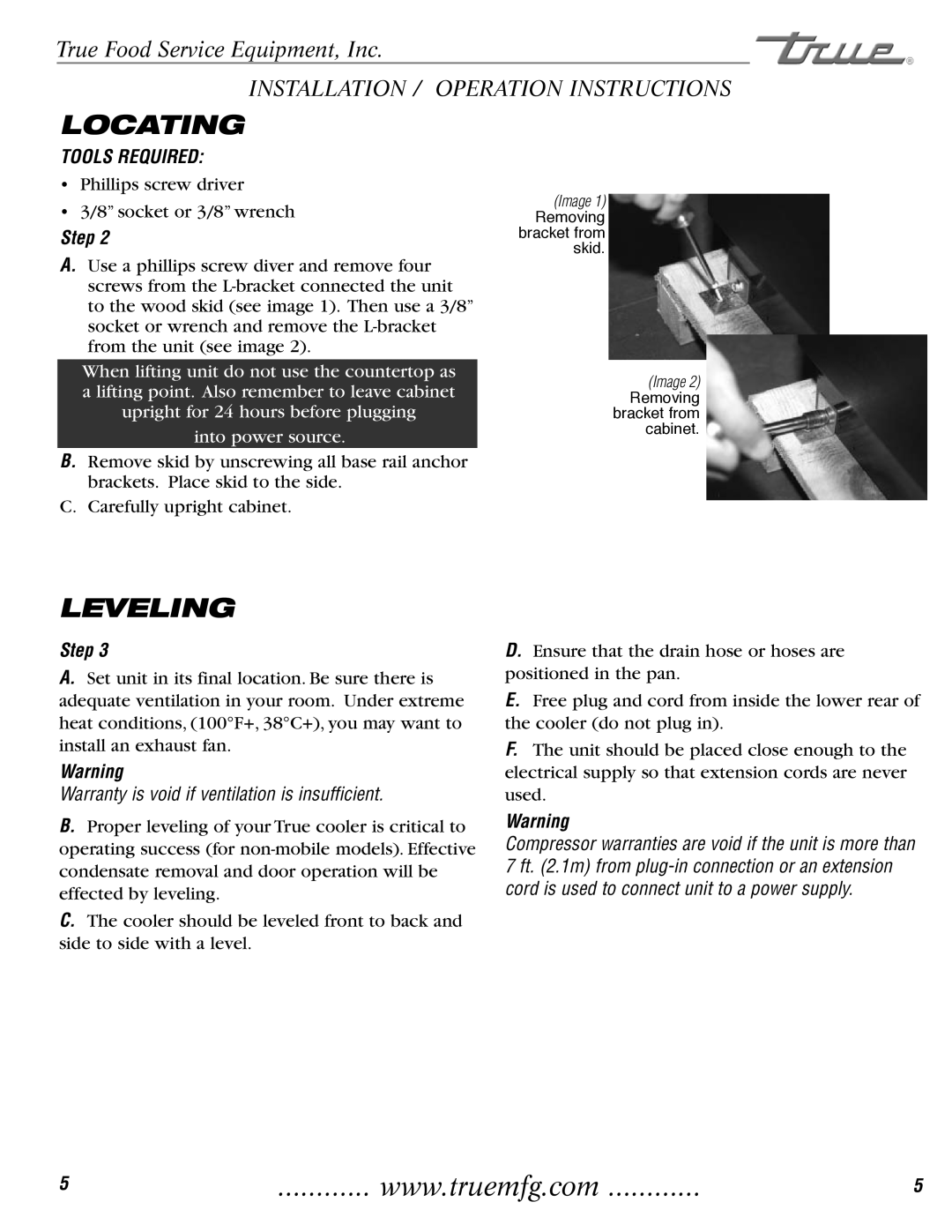

A.Use a phillips screw diver and remove four screws from the

When lifting unit do not use the countertop as a lifting point. Also remember to leave cabinet upright for 24 hours before plugging

into power source.

B.Remove skid by unscrewing all base rail anchor brackets. Place skid to the side.

C.Carefully upright cabinet.

(Image 1) Removing bracket from skid.

(Image 2) Removing bracket from cabinet.

LEVELING

Step 3

A.Set unit in its final location. Be sure there is adequate ventilation in your room. Under extreme heat conditions, (100°F+, 38°C+), you may want to install an exhaust fan.

Warning

Warranty is void if ventilation is insufficient.

B.Proper leveling of your True cooler is critical to operating success (for

C.The cooler should be leveled front to back and side to side with a level.

D.Ensure that the drain hose or hoses are positioned in the pan.

E.Free plug and cord from inside the lower rear of the cooler (do not plug in).

F.The unit should be placed close enough to the electrical supply so that extension cords are never used.

Warning

Compressor warranties are void if the unit is more than 7 ft. (2.1m) from

5 | www.truemfg.com | 5 |